What Is PEEK Tubing?

PEEK tubing, made from poly ether ether ketone, is a high-performance engineering plastic known for its exceptional mechanical strength, pressure resistance, heat resistance, and chemical stability. It is widely used in the medical field, chemical analysis, and various industrial applications due to its robust properties.

Uses of PEEK Tubing

PEEK tubing finds applications in:

- Medical tubing for catheters and chemical delivery systems.

- High-performance liquid chromatography (HPLC) for separating chemical compounds.

- Protection tubes in semiconductor manufacturing and for optical fibers.

- Alternative to metal and glass tubes in laboratories and industrial settings.

Principle of PEEK Tubing

PEEK tubing is fabricated from poly ether ether ketone, a super-engineered plastic with a linear polymer structure, ensuring high tensile strength and resistance to extreme conditions such as high temperatures, pressures, and corrosive chemicals. Despite its high cost and difficulty in machining due to its strength, PEEK’s unique properties make it indispensable for critical applications.

Characteristics of PEEK Tubing

Key features include:

- High mechanical strength, suitable for high-pressure applications.

- Exceptional heat and chemical resistance, maintaining stability in acidic and alkaline environments.

- Conformity to safety and hygiene standards, including UL standards for steam resistance and flame retardance, as well as food safety regulations.

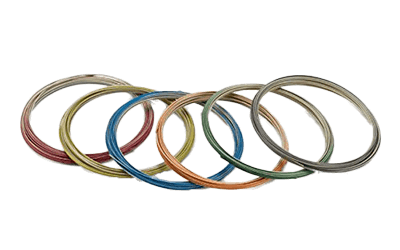

Types of PEEK Tubing

Available in various inner diameters, lengths, and colors to match specific application requirements, from ultra-thin tubes for precision work to thicker tubes for robust needs. Colored tubing aids in routing identification in complex setups.

Other Information on PEEK Tubing

1. How PEEK Tubing Is Manufactured

Manufactured primarily through extrusion, allowing for a wide range of sizes and shapes, including thin-walled tubes and custom configurations for specific applications.

2. The Future of PEEK Tubing

Continual development of PEEK tubing includes innovations like silicone rubber coatings for special conditions, enhancing its utility and performance in demanding environments.