What Is a Protractor?

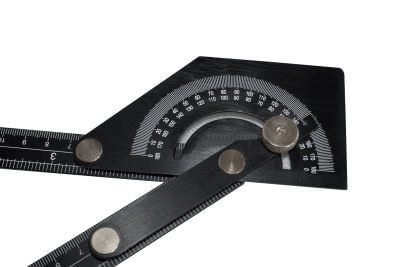

A protractor is a measuring instrument that combines a metal ruler and a protractor, used to measure angles on a workpiece. It is a type of angle meter for measuring and marking angles, with digital versions available that display angles digitally and can be zeroed at any desired angle. The scales are designed for clarity and low gloss for easy readability. Protractors are essential tools in construction sites for machine and mold assembly, measurement, plumbing, and construction work.

Uses of Protractors

Protractors are used for measuring angles and beveling on metal and wood. They feature a locknut to secure the ruler and protractor at a set angle during work. Protractors are versatile tools used in machining, mold making, jig setting, angle gauge machining, plumbing at construction sites, and building construction. They measure internal and external angles and are used in welding operations to measure the bevel angles of welded joints.

Principle of Protractors

Standard protractors are metal instruments combining a ruler and a protractor, suited for measuring outside angles. Inside protractors have two arms forming a triangle for measuring inside angles. Gauge-type protractors measure small angles such as weld bevel angles by inserting directly into the beveled product. Special protractors for welding and sheet metal work are designed to measure without interference, and slant rule protractors with strong magnets measure slopes like a level, specialized for construction work.

Types of Protractors

Protractors are designed for specific jobs, offering efficient and accurate angle measurements:

1. Standard Protractor

It is commonly used for measuring outside angles, combining a metal ruler and a protractor.

2. Digital Protractor

Features a digital angle display that can be zeroed at any angle, offering high accuracy and readability.

3. Inside Protractor

Designed with two arms for measuring inside angles by placing the arms against the angle.

4. Gauge Type Protractor

Used for measuring weld groove angles by inserting directly into the beveled product.

5. Angle Protractor

Specialized in welding and sheet metal fabrication, designed to avoid interference after welding.

6. Slant Rule Protractor

Equipped with a strong magnet for measuring slopes, specialized for construction work.

How to Select a Protractor

Selecting a protractor depends on usage, measurement range and accuracy, material, price, and scale readability:

1. Purpose of Use

Identify the purpose of choosing the suitable type, such as inside protractors for inside angles and angle or gauge-type protractors for welding work.

2. Measuring Range and Accuracy

Consider the required range and accuracy. Digital protractors offer high precision and ease of reading.

3. Material

Choose material based on the environment, with metal protractors being durable and plastic ones lightweight.

4. Price

Balance budget with needs. Higher-priced protractors generally offer greater accuracy and quality.

5. Ease of Reading the Scale

Opt for a protractor with a clear, easily readable scale and low gloss for legibility.

Consider these points to select the protractor best suited to your needs and requirements.