What Is a Booster Pump?

A booster pump is a type of pump used in conjunction with other vacuum pumps to achieve a high discharge rate. It cannot function on its own under atmospheric pressure. The discharge rate and pressure fluctuate based on the pressure supplied by the accompanying pump. Therefore, it’s essential to carefully assess the fluctuation rate before integrating the booster pump into the equipment. These pumps primarily employ positive displacement principles to transport fluids by altering the fluid volume being conveyed.

Uses of Booster Pumps

Booster pumps find applications in residential, institutional, and industrial settings. In residential and institutional contexts, they are used to transport tap water to higher floors of a building without requiring a water storage tank on the top floor. This reduces the need for maintenance, inspections, and space. In industrial settings, booster pumps are employed to enhance the air discharge rate of vacuum pumps, thereby improving productivity in semiconductor manufacturing, vacuum packaging, vacuum drying, and more.

Principle of Booster Pumps

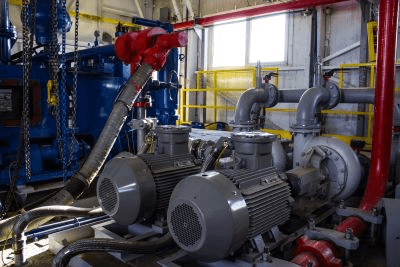

A typical booster pump comprises two cocoon-shaped rotors within a container, equipped with suction and discharge ports, and connected to a motor. Depending on the product, it may also include a non-return valve, a pressure sensor for flow rate control, and a control panel.

In operation, as the two rotors rotate, fluid is drawn in from the inlet port. As the fluid enters the gap between the rotors and rotates, it is compressed, moves toward the outlet side, and is discharged with acceleration. The rotors will only rotate without fluid inflow from the outside. Booster pumps equipped with a pressure sensor and control panel adjust the gear speed according to the pressure difference between the suction and discharge ports and the set value. They perform feedback control to align the discharge rate and pressure with the desired input values. Due to the rotational mechanism, backflow is possible, so products with backflow prevention valves or systems that prevent backflow must be used.