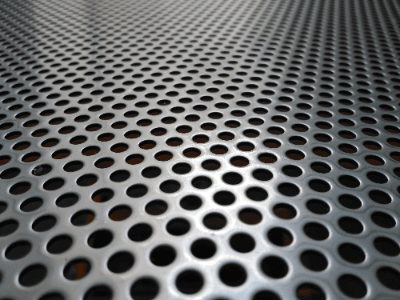

What Is Perforated Metal?

Perforated Metal is a metal sheet in which holes are punched in steel sheet (stainless steel sheet, aluminum-plated steel sheet, etc.) using a punching die.

Perforated Metal is a metal sheet in which holes are punched in steel sheet (stainless steel sheet, aluminum-plated steel sheet, etc.) using a punching die.

Perforating is a method of drilling holes in plate materials. Perforated Metal is punched with holes arranged in a regular pattern, and the use of a special die reduces the processing time.

Perforated Metal is used for safety shields to prevent people from touching it, as well as for objects and lighting that require design.

Uses of Perforated Metal

Perforated Metal can be used not only in its sheet form, but also in a wider range of applications through various processing.

Examples of applications are as follows:

1. Automobile Parts

Exhaust mufflers, air filters, oil filters, radiator covers, front grilles (the front grille of automobiles), etc.

2. Building Materials

Building exteriors, building interiors (elevators, stair railings, sunroom roofs, etc.), ceiling materials, exhaust tops

3. Plant-Related

Strainers, vents, stairs, and fences used in power plants and oil, gas, and chemical refineries

4. Centrifuges

Centrifuges, etc. used in food, chemical, pharmaceutical development, etc.

5. Electronic Equipment

Speakers, electronic storage boxes, air conditioner filters, light fixture covers

6. Furniture

Chairs, table legs, chair backs, bed frames.

Houses and appliances, kitchen and bathroom drains, microwave oven doors (to prevent leakage of radio waves), dishwasher drains

7. Other

Filters for water supply and drainage pipes, metal shelves of vending machines, aircraft engine covers, soundproofing materials, air and water filtration materials, etc.

Principle of Perforated Metal

Perforated Metal is widely used in a variety of applications, mainly for products that require metal plates with numerous regular holes.

In addition, although round holes are the most common type of holes punched in plates, it is also possible to process square holes and long round holes. For this reason, Perforated Metal is used not only for utilitarian purposes but also for decorative items. For example, Perforated Metal can be formed into cylindrical shapes, or Perforated Metal can be bent and assembled into box shapes.

Perforated Metal is processed by using a punch (convex) and a die (concave), which are used to punch numerous holes in a sheet of metal. Perforated Metal processing is capable of producing a large number of holes with a more regular distribution on a metal plate in a shorter time than other processing methods.

Perforated Metal is generally manufactured using a press machine called a turret punch press, which can now be programmed and automatically controlled to process the metal sheet.

Properties of Perforated Metal

Perforated Metal has the following properties:

1. Strength

Since the metal sheet is perforated, the weight can be reduced while maintaining the required strength of the metal sheet. In addition, since the holes are evenly arranged, stress distribution is uniform and stress concentration is less likely to occur. Perforated Metal used in the construction and automotive industries is strong and rigid.

2. Ventilation

Perforated Metal is used in construction, exhaust systems, sound control, etc., because its numerous holes allow wind and air to pass freely through the holes in Perforated Metal. High air permeability reduces increases in humidity and the formation of mold.

3. Lightweight

Perforated Metal has a perforated metal sheet structure, making it lighter than metal sheets of the same external size and of the same material. In the construction and automotive industries, Perforated Metal can be used to reduce the weight of structures and vehicles. Its light weight and ease of handling can reduce construction costs.

4. Durability

Perforated Metal is durable and can withstand outdoor environments because it is made of metal. Air, water, and snow can pass through the holes in Perforated Metal, so the metal sheet is not damaged by accumulated snow and water. This makes it suitable for use in buildings and outdoor facilities.

5. Visibility

Various hole patterns and shapes allow various designs to be expressed on buildings and furniture. A wide variety of patterns can be created by devising hole size, hole arrangement, hole shape, etc.

6. Thermal Conductivity

Perforated Metal has high thermal conductivity because it is made of metal, and is used in heat exchangers and heating equipment. Because of its high thermal conductivity, it can also be used as a heat sink.

Other Information on Perforated Metal

1. Hole Shape

Perforated Metal is generally available with round holes, but can also be processed with square or long round holes. Therefore, it is used not only for utility items but also for decorative items.

2. Manufacturing Method

Perforated Metal is manufactured using a punch (convex) and a die (concave), which are used to punch numerous holes in a sheet of metal. The press machine used to manufacture Perforated Metal is generally a turret punch press, which can now be programmed and automatically controlled to process the metal sheet.

3. Turret Punch Press

A turret punch press is a press machine that drills holes in a metal plate by fixing differently shaped dies to a circular die holder called a turret and using NC control.

NC control is a type of numerical control, a technology that uses computers to control the movements of machines and robots. NC stands for Numerical Control and means a method of moving a machine based on numerical instructions.