What Are Carbide Reamers?

Carbide reamers are precision tools designed for reaming holes with high accuracy. They are used to finish pre-drilled holes to achieve the required dimensional accuracy and surface roughness, optimizing holes for part alignment and fastening with precise internal diameters. These reamers are known for their high machining speed and accuracy, made possible by their construction from durable materials like carbide.

Applications of Carbide Reamers

Carbide reamers are employed in tasks that demand high precision, such as machining the internal diameter of holes, improving the surface roughness of machined holes, and ensuring roundness. They are essential for machining holes that require high accuracy and minimal surface roughness, such as those in machine casings or those supporting rotating shafts.

Principles of Carbide Reamers

Carbide reamers are crafted from hard materials to ensure durability and precision. They balance hardness, necessary for abrasion resistance and sharpness, with sufficient toughness to prevent tool chipping. The tools often feature a PVD coating, cobalt HSS, cermet, diamond, HSS, and powdered HSS materials. Their design includes a shallow peripheral groove and a high web thickness to maintain tool rigidity and ensure accurate machining.

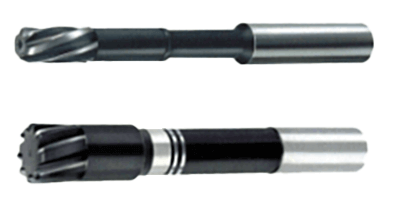

Types of Carbide Reamers

Diverse types of carbide reamers are available, each suited to specific purposes:

- Straight Reamers: The most common reaming tools, used for general purposes.

- Spiral Reamers: Feature twisted cutting edges to reduce resistance and facilitate chip ejection.

- Unequal Split Reamers: Have unevenly divided blades to reduce machining vibration and enhance precision.

- Stepped Reamers: Capable of combining multiple machining steps into one, reducing tooling costs and machining time.

- 3-Flute Reamers: Three cutting edges allow for more accurate drilling than even-numbered blade tools.

- Brazed Reamers: Use carbide only on the necessary machining parts to reduce costs, ideal for larger diameter holes.