What Is a Thickness Gauge?

A thickness gauge is a device used to measure the thickness of an object.

A thickness gauge is a device used to measure the thickness of an object.

A thickness gauge can be a contact type that measures thickness by contacting the object to be measured or a non-contact type that measures thickness without contacting the object to be measured.

Uses of Thickness Gauges

Thickness gauges are used to measure the thickness of various objects. Typical contact-type thickness gauges that measure thickness by contacting the object to be measured are calipers and ultrasonic thickness gauges. Calipers are used to measure the wall thickness of pipes, etc., while ultrasonic thickness gauges are used for items that cannot be pinched, such as tank corrosion inspection.

On the other hand, non-contact types that measure thickness without coming into contact with the object to be measured include infrared and radiation types. The infrared type is used to measure the thickness of plastic film, while the radiation type is used to measure the thickness of cold-rolled metal sheets.

Principle of Thickness Gauges

Thickness gauges are available in two types: contact-type for quick measurement and non-contact type for non-destructive measurement by shining a light on them. Thickness gauge measuring instruments of the contact type measure thickness by placing the instrument directly on the object to be measured and calculating the distance between the reference surface of the instrument and the object to be measured (relative value measurement). On the other hand, the non-contact type thickness gauge measures thickness without contacting the object to be measured, and calculates the thickness by detecting the difference between the surface and the opposite backside of the object to be measured (absolute value measurement).

Types of Thickness Gauges

Thickness gauges can be classified into contact type and non-contact type.

1. Contact Type

Thickness gauges of the contact type have the advantages of being inexpensive, convenient, and easy to see. However, because of the contact, care must be taken to avoid errors due to damage or deformation of the object to be measured. This section describes typical contact-type thickness gauges, such as calipers and ultrasonic thickness gauges.

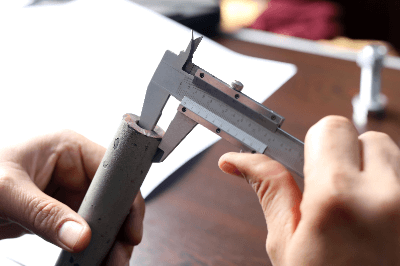

Calipers

Calipers are measuring instruments with a part that can measure length, outer diameter, inner diameter, depth, and steps, and are equipped with a scale called the main scale and sub-scale. Analog, dial, and digital calipers are available, and the digital type is widely used because it is easy to check the value. Operation is simple: slide the jaws open, slowly insert the object to be measured, and check the value.

Ultrasonic Thickness Gauge

Ultrasonic thickness gauges irradiate an object to be measured with ultrasonic waves and calculate the thickness of the object based on the propagation time of the ultrasonic waves. Ultrasonic waves are emitted from a probe (probe or transducer), which is placed in contact with the surface of the object to be measured.

The ultrasonic waves emitted from the probe are reflected from the opposite side of the object to be measured, and the thickness is calculated by measuring the propagation time until the ultrasonic waves return to the probe. The thickness is calculated by the following formula.

Thickness d = 1/2 x sound velocity of the object to be measured c x propagation time t

Since the propagation time t is a round-trip time, it can be multiplied by 1/2 to calculate the one-way time, i.e., the thickness of the object to be measured.

2. Non-Contact Type

Thickness gauges of the non-contact type are large-scale devices, but their advantage is that they can measure thickness without damaging the object to be measured. Thickness gauges of the non-contact type include the infrared type, radiation type, and laser displacement sensor type.

Infrared Thickness Measuring Instruments

Infrared thickness gauges use the property of infrared rays to penetrate specific materials to measure the thickness as an absolute value. When an object to be measured is irradiated with infrared light, the light is reflected from the surface irradiated with infrared light and the opposite back surface. The reflected light is received by the probe, and the thickness is calculated from the time difference (interference difference) of the reflected light.

Radiation Type

A thickness gauge is calculated by measuring the amount of radiation absorbed by the object to be measured. Thickness gauges are used in many products because this absorption is not affected by the color tone of the object to be measured.

The types of radiation include alpha rays, beta rays, gamma rays, and X-rays, but the principle is the same for all. Radiation is irradiated to the object to be measured, and the amount absorbed (attenuation) by the object is measured and converted to thickness. The type of radiation is selected to suit the object to be measured. The materials suitable for each radiation source are as follows:

- Alpha rays … polymer thin film

- Beta rays … thin metal films, rubber, plastic, etc.

- γ-rays/X-rays: metal plate, etc.

Laser Displacement Sensor Type

A thickness gauge is calculated by using one or two laser displacement sensors. When two laser displacement sensors are used, the thickness is calculated based on the difference in transmitted light between the surface and the backside of the object to be measured.

When two laser displacement sensors are used, the thickness of the object to be measured is calculated by measuring the distance between the upper and lower reference surfaces of the laser displacement sensor and the surface of the object to be measured, and subtracting the distance between the reference surfaces.

Thickness d = distance between reference surfaces d0 – (distance between the top of reference surface and surface of object to be measured d1 + distance between bottom of reference surface and surface of object to be measured d2)

Other Information on Thickness Gauges

Precautions for Ultrasonic Thickness Gauges

There are three types of ultrasonic thickness gauges: Zero Point/First Bottom Echo (Pulse Echo), Multiple Echo (Echo Echo), and Surface Echo/First Bottom Echo (Interface Echo).

As each has different characteristics, so it is important to choose the method that best suits the object to be measured. The most common is the pulse echo method (zero point and first bottom echo method), which can measure thick or curved parts, even if the surface condition of the object to be measured is not so good.

Note that since the ultrasonic thickness gauge uses ultrasonic waves, it cannot measure materials that contain air bubbles through which ultrasonic waves cannot pass, such as styrofoam, or rubber, which cannot receive ultrasonic waves because they are attenuated.

In addition, the layer of air has acoustic resistance and inhibits the propagation of ultrasonic waves between the probe and the object to be measured. For this reason, a special liquid called a contact catalyst (couplant) must be applied between the probe and the object to eliminate the acoustic resistance of the air as much as possible.