What Is a Palletizer Robot?

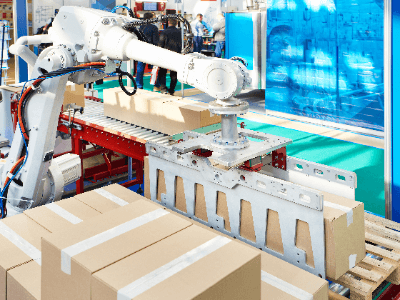

A Palletizer Robot is a type of robot used in the manufacturing and logistics industries.

They automatically transport products and goods and place them on pallets. Palletizer Robots are used for packing and stacking products and for cargo handling in distribution centers and warehouses.

This makes production processes more efficient and improves the work environment, while also reducing labor and being part of technological innovations.

Uses of Palletizer Robots

The main applications of Palletizer Robots are as follows:

1. Manufacturing Industry

Palletizer Robots are used in manufacturing to automatically handle and feed product parts or the product itself to the assembly line. As part of the assembly process, parts and components must be accurately positioned.

2. Food Industry

In the food industry, food and beverage containers are stacked on pallets and packed. Palletizer Robots are responsible for automatically stacking and packing products according to the type and size of the food or beverage.

3. Logistics

In warehouses and distribution centers, incoming products are stacked on pallets for storage, and pallets must be dismantled to transport products for shipping. Palletizer Robots perform efficient loading and unloading operations and speed up the logistics process.

4. Pharmaceutical Industry

In the pharmaceutical and medical device manufacturing industries, product handling and packaging operations must be extremely accurate and sanitary. Palletizer Robots provide the right solution for working in these environments.

5. Automated Warehouses

Automated warehouses and fulfillment centers have proliferated in recent years. These facilities utilize Palletizer Robots to automate the picking and packing of products.

6. Heavy Industry

Palletizer Robots also play an important role in handling heavy machinery and large products. This reduces the risk of exposing humans to hazardous work environments.

Palletizer Robot Principle

1. Object Detection and Acquisition

First, the Palletizer Robot uses sensors and machine vision systems to detect the position and shape of an object. It then moves its arm to hold the item.

2. Placing the Item on the Pallet

Next, the robot brings the item to the appropriate position and places it on the pallet. In this process, the robot controls the spacing between items and the placement pattern to achieve stable stacking.

3. Programming and Control

These detection, holding, and placement are based on pre-programmed instructions. The robot’s control system receives commands containing information on how to move, grasp, and place items, and operates accordingly.

4. Control Algorithm

Palletizer Robots use appropriate control algorithms to ensure efficient placement, taking into account the position, weight, and shape of the goods. Algorithms are important to maintain an optimal balance of safety and efficiency.

5. Sensors and Safety

Palletizer Robots have built-in safety features to avoid collisions with obstacles and people. This ensures safety during operation.

6. Self-Compensation Function

Some Palletizer Robots incorporate a self-compensation function to accommodate positioning errors or fluctuations in the position of the item. This ensures that accurate placement is maintained.

Types of Palletizer Robots

The main types of Palletizer Robots are as follows:

1. Layered Palletizer

This type of robot arranges products of the same size and shape in multiple layers and stacks them on pallets. It has the ability to handle multiple products at one time, allowing for fast and consistent operation.

2. Case Palletizer

Case Palletizer Robots have the ability to individually handle and stack pallets of products of various sizes and shapes. They are highly flexible because they can adapt to fluctuating product sizes and types.

3. Hybrid Palletizer

Hybrid Palletizer Robots are robots that can perform a combination of different types of palletizing tasks. For example, it can perform layer palletizing and case palletizing simultaneously.

4. Robot Arm Palletizer

This is a type of robot that uses an articulated robot arm to perform tasks. Its ability to grasp objects and its versatile range of motion allows it to be positioned in a variety of ways.

5. Portal Palletizer

Portal-type Palletizer Robots use a gantry (a support structure that raises and lowers) to move the material. They are suitable for handling large, heavy products.

6. Scalar Robot

SCARA robots use an arm that extends in a straight line to perform work. They generally specialize in linear movement and are suitable for palletizing products of specific shapes and sizes.

7. Armless Palletizer

Armless Palletizer Robots do not have arms and instead use conveyors or transfer mechanisms to move goods. This can be a simpler and more efficient solution in certain situations.