What Is a Linear Power Supply?

A linear power supply converts commercial AC power to DC power. It uses either a linear power supply or a switching-regulated power supply to stabilize the circuit and reduce voltage fluctuations.

Linear power supplies have been around since the days when vacuum tubes were used. A variable resistor or three-terminal IC is incorporated into the circuit to continuously control the power from the input and adjust the output voltage. It operates with analog control.

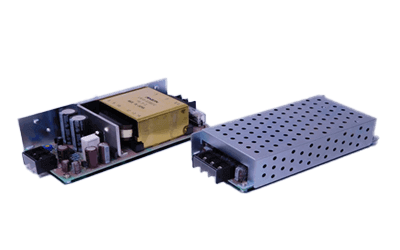

Although the output voltage accuracy is good, the device is large and heavy, and the internal power loss is large, resulting in low efficiency and high heat generation by the variable resistor.

Uses of Linear Power Supplies

Lightweight and compact switching power supplies are often used these days, but linear power supplies are often used for small output power supplies and when noise is to be suppressed.

Although they are larger, they produce less noise and are used in measuring instruments, medical equipment, and high-end audio equipment. They are also used in cordless telephones, desktop computer speakers, power tools, etc. Linear power supplies using three-terminal ICs were especially popular because of their relatively small size and ease of use.

Principle of Linear Power Supplies

Linear power supplies have simple circuit configurations and low noise. A commercial AC power source is extracted, and a variable resistor is placed in series to remove excess voltage to create a DC power source. The removed voltage becomes heat energy with the resistor, increasing the heat generated. Therefore, a heat sink is required at the regulator.

The circuit has a simple structure because it only uses resistors, but the heat cannot be controlled.

There are series regulators and shunt regulators, but series regulators are generally used and shunt regulators are used in limited applications. Zener diodes and three-terminal ICs are used.

Depending on the application, it is necessary to consider whether or not the linear power supplies can withstand the heat generated by the linear power supplies. In addition, since the noise of linear power supplies can be suppressed to a smaller level than that of a switching power supply and the sound quality can be improved, a person who is particular about audio equipment may make his or her linear power supplies to achieve the sound quality he or she desires.

1. Grounding of Noise-Cut Transformers

There are measures to prevent noise between the ground of an electric circuit and ground, even in places where the potentials are different or where the ground is not groundable. Even in such cases, try installing a noise-cut transformer first. If this does not seem to work, the first is to ensure that the location where the noise-cut transformer is installed makes contact with the ground over as large an area as possible. The second is to make the input and output cables into shielded wires that can shield noise and to install this shielded wire and the case of the noise-cut transformer over a large area. The above operations are expected to improve the noise rejection effect.

2. Structure of Noise Cut Transformers

This section describes the structure of a noise-cut transformer. Before that, when you want to cut noise, the measure generally taken is to insulate the noise source. By insulating the source of noise, the noise will have almost no effect. In most cases, a photocoupler is used in the circuit. Another method that can be used when a photocoupler is not used is an isolation transformer. From the standpoint of cost and space, it is preferable to use a photocoupler on a circuit board, but an isolation transformer is used if a circuit board cannot be used.

However, isolation transformers are not a panacea, and the secondary winding is also affected by noise coming from the primary winding. This is where noise-cut transformers come in. This transformer is not just an isolation transformer but a fault wave isolation transformer. Details of its principle and operation are omitted here, but its structure is introduced here.

The structural features of the noise-cut transformer are, in addition to the conventional insulated transformer structure, multiple encircling electromagnetic shielding plates on the outer circumference of the coil transformer. This is the most significant feature. Furthermore, the coil arrangement, core material, and shape are designed so that the magnetic flux of high-frequency noise does not interlock with each other, preventing the transmission of noise by distributed capacitance coupling and electromagnetic induction, making it an extremely excellent transformer for noise isolation.