What Is Beryllium Copper?

Beryllium Copper (BeCu) is a copper-based alloy to which 0.5-3.0% beryllium is added.

While maintaining the high electrical and thermal conductivity of copper, BeCu has high strength and durability comparable to those of special steels, as well as heat and corrosion resistance.

Specialty steels are iron alloys that have unique properties compared to ordinary iron alloys. They are synthesized by adding nickel, chromium, and other elements. Therefore, Beryllium Copper is said to have the best balance of properties of all copper alloys. Beryllium Copper’s superior properties make it a highly reliable component in a wide variety of industries.

Uses of Beryllium Copper

The following are the four main applications of Beryllium Copper.

1. Conductive Spring Materials

Conductive spring materials are materials that can conduct electricity and can be coiled and used as springs. Beryllium Copper in plate or wire form is highly conductive, strong, and durable. This property is used as a conductive spring material for electronic components in automobiles, industrial equipment, cell phones, and home appliances.

2. Sliding Parts

Sliding parts are materials used for parts in contact with each other. Beryllium Copper has high strength and durability, as well as excellent abrasion and galling resistance against steel materials. Therefore, it is used for sliding parts such as landing gears of aircraft.

3. Electrode Member for Resistance Welding

Resistance welding is a welding method that uses the resistance heat generated when electricity is applied to the metal to be welded. Electrode materials for resistance welding are materials used for the electrodes that conduct electricity used in resistance welding.

In addition to high electrical conductivity, resistance welding electrode materials must also be durable because of the pressure applied to them. Beryllium Copper is used in the automotive and other industries as an electrode material for resistance welding because of its high conductivity, high strength, and high durability.

4. Safety Tools

Beryllium Copper has high strength comparable to that of special steel, yet is non-igniting, non-magnetic, and corrosion resistant. Therefore, it is used in pliers and wrenches as safety tools to prevent explosions at work sites.

Strengthening Mechanism of Beryllium Copper

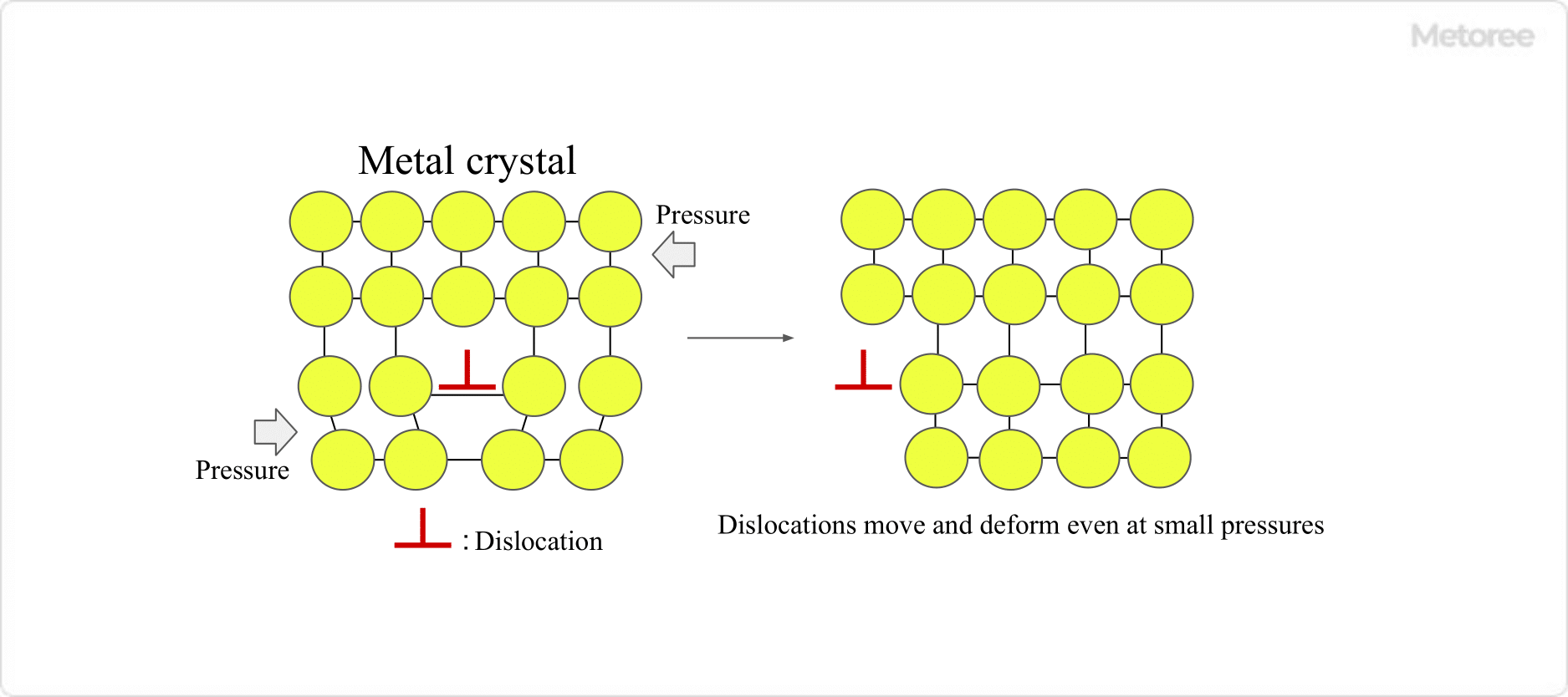

The interior of metals contains many atomic arrangement defects called “dislocations. As these dislocations move through the crystal, the metal crystal is deformed. Therefore, in order to increase the strength of a material, it is necessary to suppress the migration of “dislocations” to prevent them from moving as much as possible.

Figure 1. Dislocation movement

Generally, alloys such as iron, titanium, and aluminum are heat treated to increase their strength. This is done using solid solution strengthening and precipitation strengthening, two of the most common methods of metal strengthening.

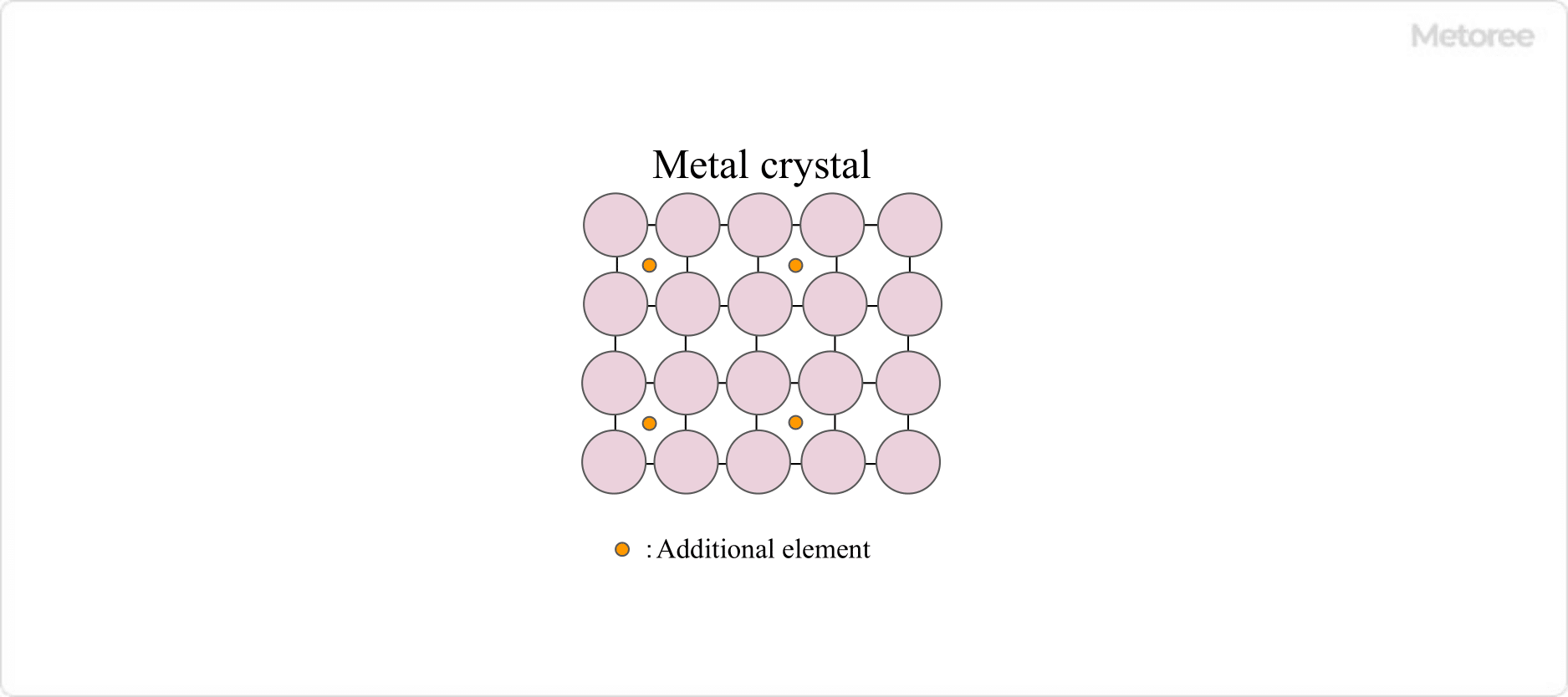

1. Solid Solution Strengthening

Solid solution strengthening is a method of strengthening a material by dissolving alloying additive elements into the metallic elements of the base metal phase and dispersing the additive elements uniformly in the base metal phase. When elements of different sizes are mixed, strain occurs around the mixture. As a result, dislocation migration is inhibited and the metal is strengthened. In the case of beryllium copper, the base metal is copper and the additive element is beryllium.

Figure 2. Solid solution strengthening

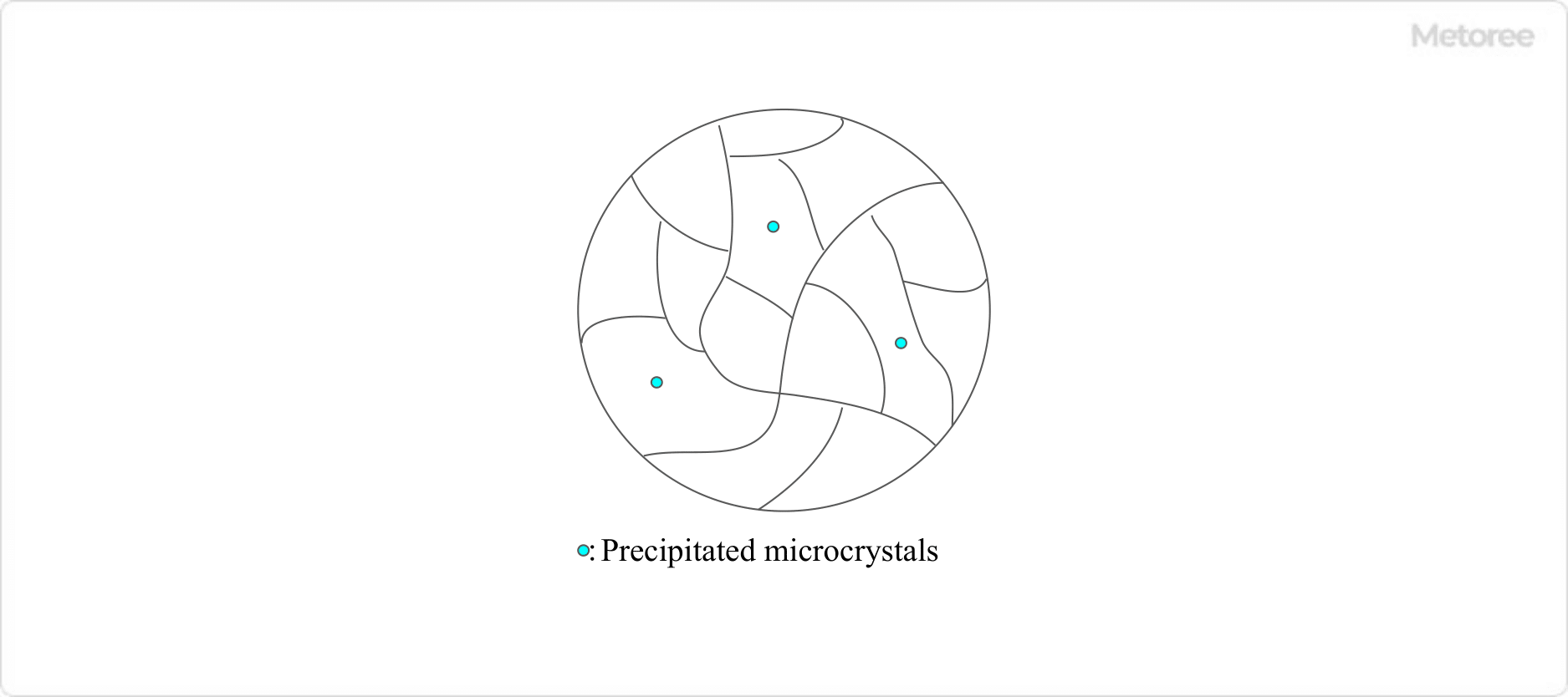

2. Precipitation Strengthening

Precipitation strengthening is a technique to strengthen a metal by precipitating nano-level fine and hard crystals within the crystals, thereby inhibiting the movement of dislocations. To precipitate fine crystals, a heat treatment called aging is used. Fine crystals precipitate as the aging heat treatment time progresses. However, care must be taken because if the aging time is too long, the fine crystals coarsen and the metal crystals soften.

Figure 3. Precipitation strengthening

Beryllium Copper is also heat treated at appropriate temperatures and times to obtain strength and properties comparable to those of specialty steels.

Other Information on Beryllium Copper

Regulations and Handling of Beryllium Copper

Because Beryllium Copper contains beryllium, there are sometimes concerns about restrictions on its use due to environmental and health concerns. However, there are currently no laws or regulations that restrict the use of Beryllium Copper, and the EU RoHS Directive, ELV Directive, and REACH Regulation are not applicable to Beryllium Copper. However, since beryllium itself is highly hazardous, Japan’s PRTR system obliges companies to report to the government the amount of emissions and transfers depending on the size of their business and the amount handled.

In terms of occupational health, Beryllium Copper is exempt from the Ordinance on Prevention of Hazards due to Specified Chemical Substances because its beryllium content is less than 3%, and there is no health risk during normal use. However, protective measures such as local exhaust ventilation and dust masks are recommended for welding, dry grinding, polishing, and other processes that generate fumes and fine dust.