What Is an Insert Nut?

An Insert Nut is a material used to increase the strength of the fastening portion of a plastic material. Since resin is less strong than bolts, insert suts, which are mainly made of metal, are embedded in resin to strengthen the joint.

An Insert Nut is a material used to increase the strength of the fastening portion of a plastic material. Since resin is less strong than bolts, insert suts, which are mainly made of metal, are embedded in resin to strengthen the joint.

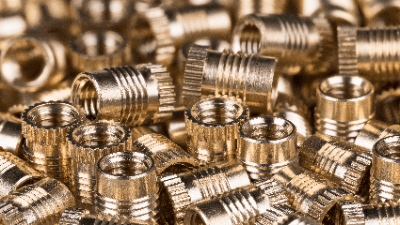

The outer surface of the insert nut is knurled so that it can be adhered to the resin, and the inner surface is a nut-threaded member.

Insert nuts are generally made of free-cutting brass or lead-free brass, which has excellent machinability and ductility. Aluminum or stainless steel may also be used. Resin inserts are also available and are used for automotive and other applications.

There are two methods of inserting insert nuts into plastic parts: inserting the insert nut when the plastic is molded, or inserting the insert nut after the plastic is molded.

Usage of Insert Nut

Insert nuts have a wide range of applications for reinforcing fasteners of plastic parts. The main uses are for fastening parts of resin parts in automobiles, motorcycles, trains, aircraft, and other transportation equipment, smartphones, home appliances, and industrial machinery.

Particularly in the automotive industry, plastic parts are being used to reduce weight in order to improve fuel efficiency. In addition, environmentally friendly bioplastics are increasingly being adopted.

Insert nuts are widely used to fasten these plastic parts. Insert nuts themselves are also being developed made of high-strength resin, contributing to weight reduction.

In machine tools, insert nuts are often used in machining centers, NC machine tools, servo motors, and control panel housings for inverters, etc.

Types of Insert Nuts

There are many types of insert nuts, depending on the combination of shape, material, and insertion method.

There are two types of insert nut shapes: standard type and flange type. The standard type is the most common type and the least expensive. The standard type is further divided into two types: single-sided and double-sided.

The single-sided type has a fixed mounting direction for press-fitting, while the double-sided type is chamfered on both sides so that it can be inserted from either side during press-fitting.

The flange type has a flange on one side and can be inserted in only one direction.

There are also different methods of inserting insert nuts into plastic members.

Other Information on Insert Nuts

Insert Nut Insertion Method

There are two methods of embedding insert nuts into resin: insert during molding and insert after molding.

Post-molding inserts are mainly used for thermoplastic resins that soften when heat is applied.

For thermosetting resins, which harden when heat is applied, post-molding inserts can also be used, although most of them are done at the time of molding.

1. Insert during molding

When molding a resin material, an insert nut is attached to the mold and the resin is poured into the mold. Although the insert nut needs to be assembled to the mold, the resin is melted and inserted around the insert nut, so it has excellent strength after cooling.

2. Insert after molding

There are three methods of inserting after resin molding: expansion method, press-fit method, and thermal press-fit method.

Expansion Method

Insert nut is press-fitted into the bottom hole of the resin member and fixed to the resin member by expanding the tip of the nut. After the insert nut is driven into the plastic member with a hammer, the tip of the insert nut is expanded by pushing the expansion plate downward using a special punch or other tool.

This method is characterized by the fact that it is not affected by the shape of the boss into which the nut is inserted on the material side, and it does not require a heat source.

Press-fit method

This is the most common method. A press or hammer is used to press-fit the nut into the plastic material without using a heat source. Although a larger boss diameter can prevent the boss from cracking, it is necessary to change to the thermal press-fit method depending on the resin material.

Thermal press-fit method

This method uses a heat source to press-fit the insert nut into the plastic part. The insert nut is set in the bottom hole of the part, and the nut is press-fitted while being heated by a soldering iron, ultrasonic welding machine, or thermal press-fit machine.

By applying heat to the insert nut, the heat is transferred to the resin material and softens it, allowing the insert nut to be easily press-fitted into place. Also, since the resin is melted as it is press-fitted, the melted resin is absorbed into the nut, increasing its strength. This method is not affected by the boss shape on the resin member side.