What Is Nylon Tubing?

Figure 1. Overview of Nylon Tubing

Nylon Tubing is a tubing manufactured from nylon resin and intended primarily for plumbing applications.

They are used in a variety of industries for fluids such as air, water, and lubricating oil.

Advantages include excellent flexibility for easy working and low cost. Depending on the product, nylon tubing has excellent pressure resistance, heat resistance, chemical resistance, oil resistance, vibration resistance, and corrosion resistance.

Uses of Nylon Tubing

Nylon Tubing is used for lubrication, pneumatic, hydraulic, and other piping applications as an alternative to copper and other conventionally used pipes. Specifically, nylon tubing can be used in oil and pneumatic equipment, centralized lubrication equipment, coating equipment, and chemical plants.

Nylon Tubing can also be used for piping in tight spaces or where complicated flow lines must be taken, by taking full advantage of nylon’s superior flexibility.

Other types of nylon tubing include more flexible types that can be used in oscillating sections, and special nylon tubing made of nylon that specializes in high pressure and chemical resistance.

Principle of Nylon Tubing

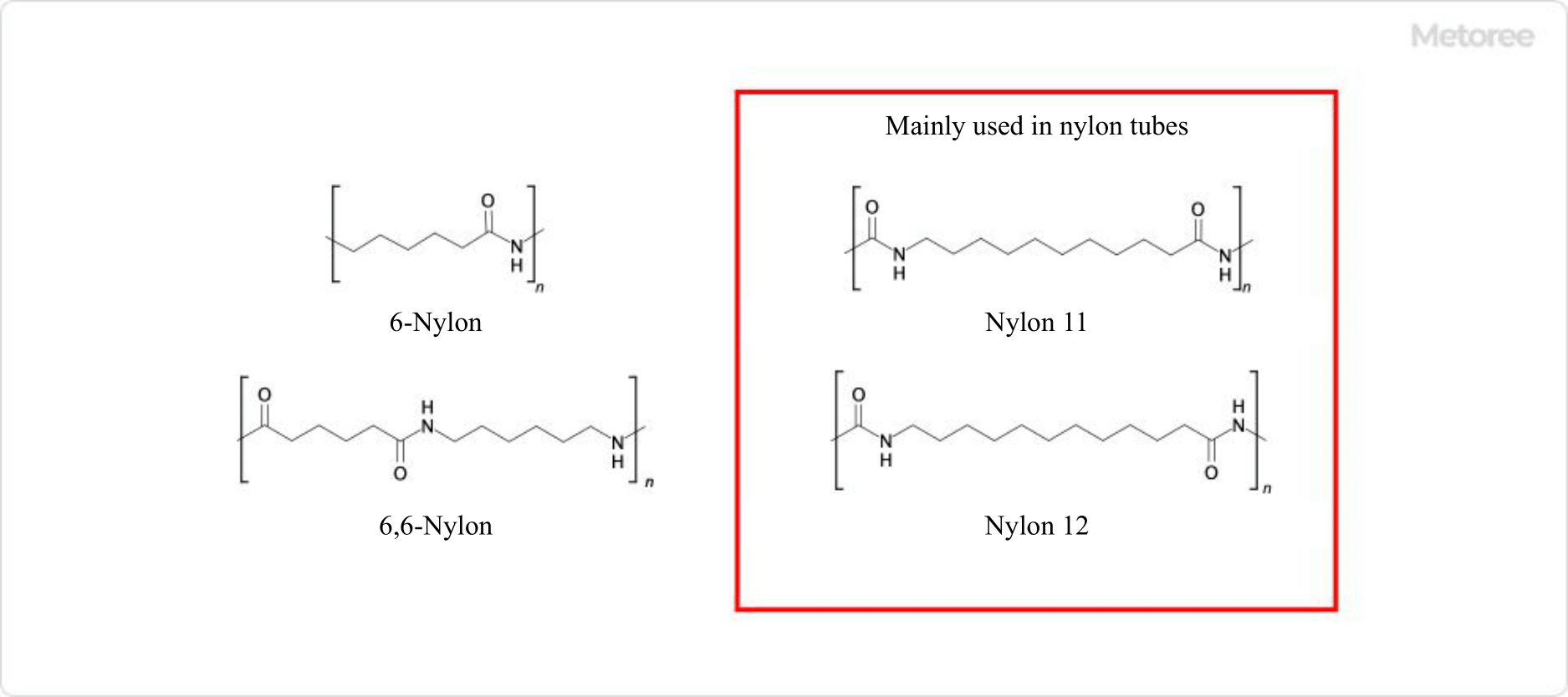

Figure 2. Structural formulas for various nylons

Nylon Tubing, like fiber materials, is strong against expansion and contraction, and has strong abrasion resistance and toughness. At the same time, it has high resistance to heat, impact, and chemicals.

First developed, 6,6 nylon was the world’s first synthetic fiber to be widely used. Today, polyamide is commonly referred to collectively as nylon.

While 6 nylon and 6,6 nylon are commonly used for nylon products themselves, nylon 11 and nylon 12 are often used for Nylon Tubing. This is because nylon 11 and nylon 12 have superior resistance to impacts and temperature changes.

The numbers in these names are derived from the number of carbon atoms in the monomer raw material used to make nylon. Soft hoses are manufactured with plasticizers to provide flexibility, while rigid tubing without plasticizers is called rigid unplasticized Nylon Tubing. Other types of nylon may also be used, such as nylon that has been strengthened by processing.

How to Select Nylon Tubing

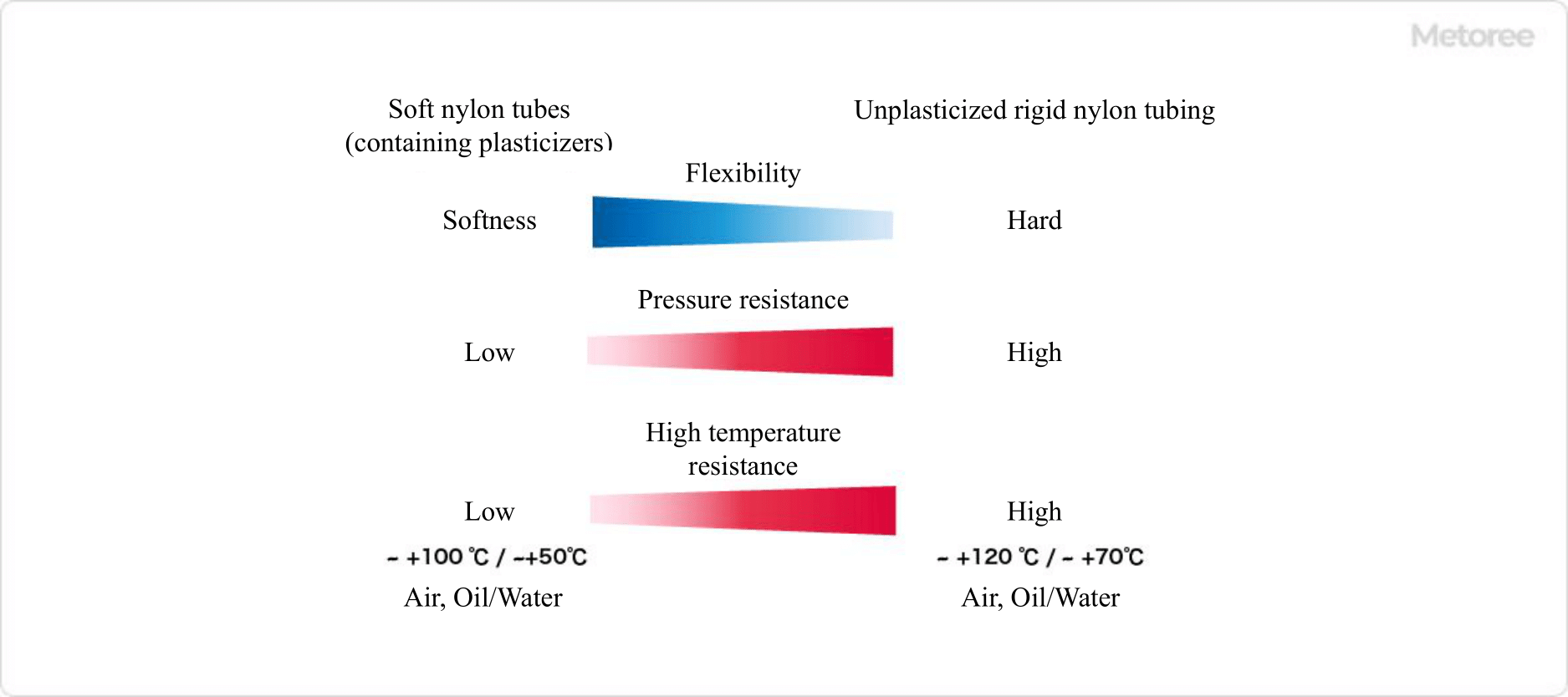

Figure 3. Properties of soft and hard nylon tubes

Nylon Tubing varies in pressure resistance, heat resistance, and flexibility depending on the product. It is important to select the product that best suits your application.

1. Flexible Nylon Tubing

Tubing flexibility varies depending on whether or not a plasticizer is incorporated. Soft Nylon Tubing contains a plasticizer and has excellent flexibility. In terms of pressure resistance and heat resistance, the performance is slightly lower than that of unplasticized nylon, but there are products that can handle high pressure. In addition, there is no difference in the fact that the main component is nylon, so the performance is not significantly inferior.

However, low molecular weight substances called monomers and oligomers contained in the resin may precipitate on the tube surface via the plasticizer and adhere to the surface like white powder. Generally, this does not degrade performance such as pressure resistance or chemical resistance, but there is a tendency for the flexibility of the tube to decrease in the future.

2. Unplasticized Nylon Tubing

Those without plasticizers are called unplasticized Nylon Tubing and are the most rigid. It also has the highest pressure resistance and heat resistance, and can be used under high pressure and high temperature.

Some products are available in a variety of colors, and different colors can be selected for each pipe to distinguish them by color coding. However, since black is superior in terms of weather resistance, some manufacturers recommend black tubing if no particular choice is necessary.

In addition, if chemicals are to be used as fluids, it is necessary to check whether the tubing has chemical resistance to the chemicals to be used before use.