What Is a Power Relay?

Power relays are relay components capable of carrying a current greater than 3A.

Power relays are relay components capable of carrying a current greater than 3A.

Relays can be roughly classified into two types: contact relays and non-contact relays, and power relays are contact relays. Power relays are of robust construction to withstand large currents, as they are expected to carry larger currents than general control relays.

Because of their characteristics, power relays are sometimes used as relays for safety circuits when an abnormally large current flows in a circuit.

Uses of Power Relays

Power relays are one of the most widely used components in industry.

The following are examples of power relay applications:

- Circuits for solar panels and their power feeders

- Driving large powered robots

- For driving elevators and heavy equipment at construction sites

- In charging facilities for electric vehicles, etc.

- Main circuits of hybrid cars

Principle of Power Relays

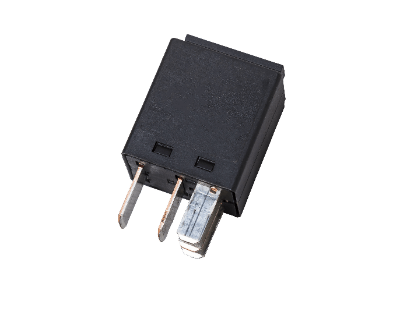

Power relays are composed of terminals, contacts, and electromagnetic coils.

1. Terminals

The terminal is the part that connects to the wiring. In many cases, Power Relays are fixed to the wiring by solder wear. In other cases, Power Relays are mounted on a terminal block unit and the wiring is connected to round terminals or other terminals that have been processed.

2. Contacts

Contacts are driving components that provide a path for electricity. There are larger and more numerous contacts with a higher current application.

To reduce electrical resistance, silver alloys and gold are used for contacts. Silver alloys are widely used because of their low electrical resistance. Gold alloys are more resistant to oxidation than silver alloys, but they have a lower melting point and are more expensive, making them suitable for small loads.

There are two types of contacts in power relays: movable contacts and fixed contacts. Fixed contacts are firmly fixed to the casing or other components. The movable contacts are driven together with the movable iron strip, and when they make contact with the fixed contacts, they conduct electricity.

3. Electromagnetic Coil

The electromagnetic coil is a component that drives the movable iron strip by electromagnetic force. The movable iron strip has a movable contact point, which is brought into contact with the fixed contact point by the electromagnetic force of the electromagnetic coil. When the electromagnetic coil is de-energized, the contacts are pulled apart or in contact with each other by a spring.

Types of Power Relays

Power relays are broadly classified into DC-driven relays and AC-driven relays.

1. DC Driven Power Relay

DC-driven relays are power relays in which the coil is driven by a DC power source. DC power sources are resistant to inductive voltages and are characterized by stable operation even at low voltages. The relay coil is often connected to a diode to prevent reverse current.

The standards include 5 VDC, 12 VDC, 24 VDC, etc., which are used according to the intended use. A 24V power supply with a higher voltage is used when the transmission distance is long or when a relay circuit is built in a control panel. For intrinsically safe explosion-proof circuits, 12 VDC, 5 VDC, etc. are used.

2. AC-Driven Power Relay

The AC drive is a power relay whose coil is driven by an AC power source. The commercial power supply is AC power and can be used directly, eliminating the need for a power supply required for the DC version.

Coil voltages of 100 VAC or 200 VAC are used; AC400 V control circuits are rarely used due to the difficulty of maintaining isolation distances.

Other Information on Power Relays

Power Relay Failures

Power relays are mechanically actuated by electromagnetic forces and have a limited life span. The life expectancy in terms of number of operations is about several hundred thousand times.

If the life is exceeded or excessive shocks are applied, the following failures can occur:

1. Coil Disconnection

This is a failure in which the electromagnetic coil in the power relay is disconnected. The coil disconnection causes all contacts to cease operation. This failure is relatively easy to detect because there is no sound of the contacts operating.

2. Welding

This is a failure that occurs when excessive current flows through the power relay, causing the contacts to weld together and not open. Diagnosis is made by switching the relay on and off and checking the continuity of the contacts.

3. Inoperative Contacts

This is a malfunction in which the relay contacts become frayed or dirty, resulting in a loss of electrical continuity. The contacts remain open without shorting. Diagnose by checking continuity and voltage, as in the case of welding.

4. Short-Circuiting of Coils

This is a failure that occurs when the varnish on the electromagnetic coil peels off, resulting in a short circuit. When the electromagnetic coil is energized, the control power supply itself is tripped, and this is identified.

Since control circuits often have multiple power relays connected in parallel, it may take some time to detect the fault.