What Is a Pelletizer?

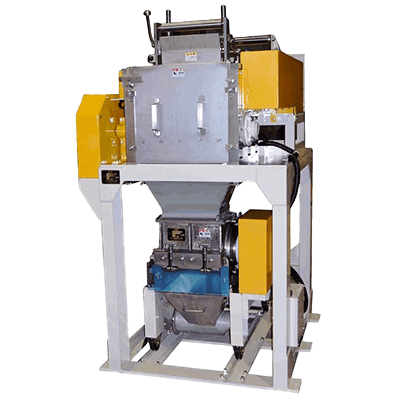

A pelletizer is a mechanical device designed to convert raw materials into small, pelletized forms. This process involves heating and compressing materials such as plastics, metals, feed, and chemicals into pellets.

These pellets are easy to handle, transport, and store, offering consistent shapes and sizes. Pelletization improves the efficiency of storage and transportation and finds applications in various industries.

Regular maintenance and cleaning, particularly of cooling devices and machine components, are essential for optimal performance.

Uses of Pelletizer

Pelletizers are used in various industries, including:

1. Plastic Product Manufacturing

In plastic manufacturing, pelletizers shape raw materials into uniform pellets, improving production efficiency.

2. Recycling Industry

They pelletize waste plastics and other recyclable materials for easier reuse and recycling.

3. Feed Manufacturing Industry

Pelletizers are used in livestock and aquaculture industries to produce convenient, appetizing feed pellets.

Principles of Pelletizer

A pelletizer combines heating, compression, and cooling to form consistent pellets. It starts with feeding raw materials at a constant rate, often followed by heating to melt or plasticize the material.

After heating, the material undergoes compression, typically using pressure rollers or screw compressors, to achieve the desired shape. The pellets are then cooled to solidify and reach the desired hardness before advancing to the next processing step.

How to Choose a Pelletizer

When selecting a pelletizer, consider:

1. Raw Material

Choose a pelletizer compatible with the melting temperature, viscosity, and plasticity of the material being processed.

2. Cut Dimensions

Ensure the pelletizer supports the required pellet dimensions, such as diameter and length.

3. Processing Capacity

Select a pelletizer with a processing capacity that matches your production needs.

4. Durability

Choose a durable pelletizer with a robust structure and plan regular maintenance and cleaning.

Other Information on Pelletizer

Terminology Based on Pelletizer Types

Different pelletizer types are named based on their processing methods:

1. Angular Pelletizer, Sheet Pelletizer

Used for cutting sheet materials like plastics and rubber into square-shaped pellets. Often operates at room temperature and may not require cooling water.

2. Strand Cutter, Round Pelletizer

Cuts extruded rope-like materials into cylindrical pellets. Common in plastics processing, this method often involves cooling during cutting.

3. Pelletizer

A general term for devices solidifying powders, fine particles, or liquids into spherical or granular shapes. Various types exist, including agitating and extruding types, often requiring binders for granulation.