What Is SAW (Surface Acoustic Wave)

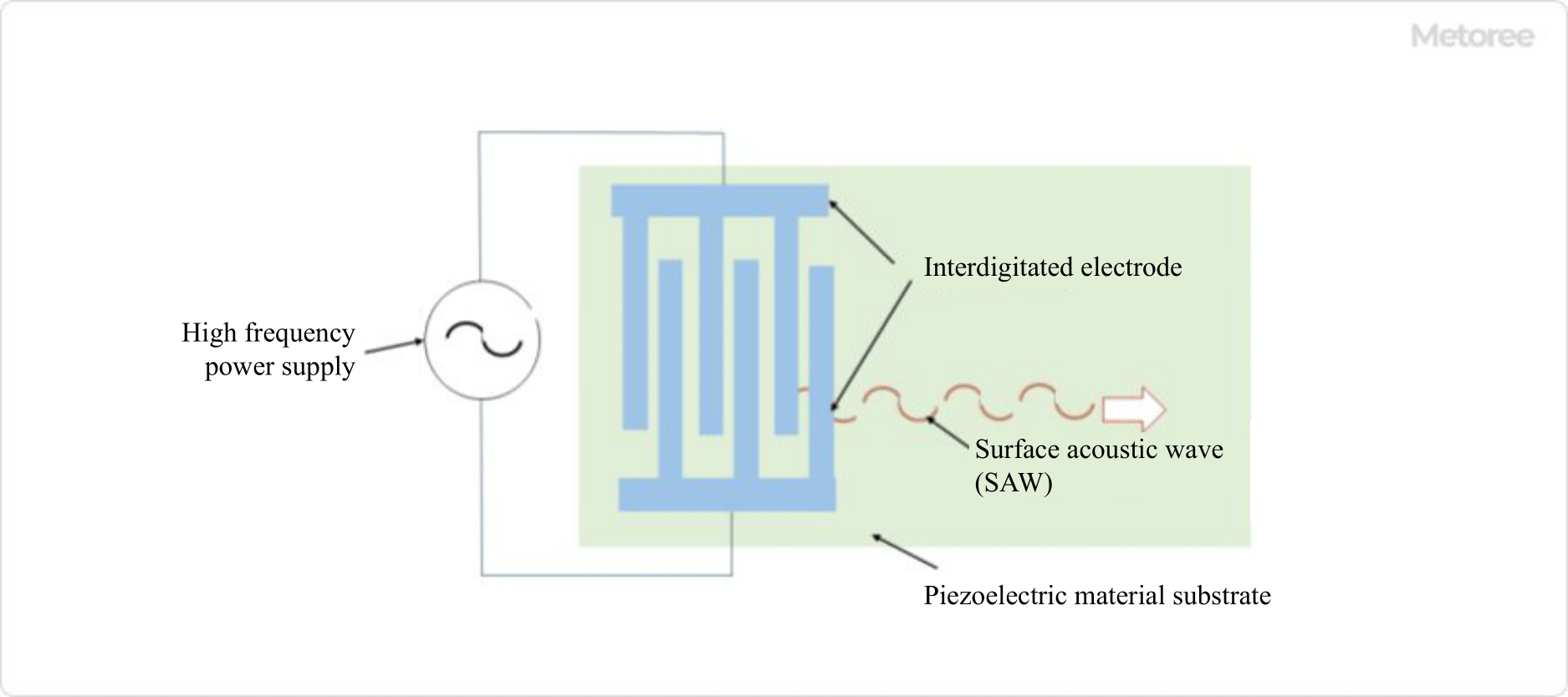

Figure 1. The basic structure of IDT (SAW element) transmitter

SAW (Surface Acoustic Wave) is an elastic wave that propagates only in the vicinity of a piezoelectric material surface.

The nature of the propagation of elastic waves near a solid surface, one of which is a gas, a liquid, a vacuum, or another solid material, is different from that of infinitely expanding (bulk) solids, liquids, or gases. In particular, when the solid substrate material is a piezoelectric material, the piezoelectric effect (piezoelectric effect) generates a surface acoustic wave (SAW) that propagates near the surface in a specific direction when subjected to strain.

The propagation speed of a SAW is about 1 to 5 km/s, about 1/100,000th of the speed of electromagnetic waves, making it possible to miniaturize the circuit.

Principle of SAW (Surface Acoustic Wave)

When piezoelectric material is sandwiched between two electrodes and strain is applied between the electrodes, a voltage is generated (piezoelectric effect), and vice versa (reverse piezoelectric effect).

When a high-frequency voltage is applied between the two electrodes, the IDT generates high-frequency surface acoustic waves and functions as a SAW transmitter.

If an extremely high-frequency voltage is applied, an ultrasonic SAW can also be generated. Conversely, when the IDT receives an SAW, a high-frequency voltage is generated in the IDT, which functions as an SAW receiver. By adjusting the number and shape of the combs, the substrate material, and its thickness, it is possible to generate and receive SAW with various characteristics.

By transmitting and receiving SAWs at the transmitter and receiver, the frequency of the SAW can be modulated by sensing the properties of the substrate between the transmitter and receiver or by placing specific films or elements on the substrate. This property is the reason why SAW is used in a variety of applications.

Applications of SAW (Surface Acoustic Wave)

The range of applications for SAWs is expanding significantly. Some examples are shown below:

1. Application to Electronic Components

SAW filters are widely used in cell phones, radio receivers, TV receivers, digital receivers, etc.

2. Micro Manipulation of Liquids and Droplets

Microfluidic pumps can be created by placing microfluidic droplets on a substrate and taking advantage of the fact that SAW can be transferred to the fluid on the substrate and accelerate the fluid due to large inertial forces. On the substrate, the SAW is a transverse wave, and when it enters the droplet, it becomes a longitudinal wave and creates a vortex, which causes a mixing effect of the fluid droplets. Using SAW as a driving mechanism, droplets are pushed toward two or more outlets for sorting. It is also used to size and split droplets.

3. Flow Sensor

Multiple IDTs (transmitters and receivers) are placed outside the liquid flow pipe, usually non-wetted. SAWs generated by one transmitter propagate into the liquid at a specific angle, producing both forward and reverse received waves as they pass through the liquid. The time difference between the emitted and received waves, which pass through the liquid one to several times, correlates to the flow velocity. By comparing and calculating the time difference between the outgoing and incoming waves, the flow rate and other parameters can be measured.

4. Application to Gas Sensors

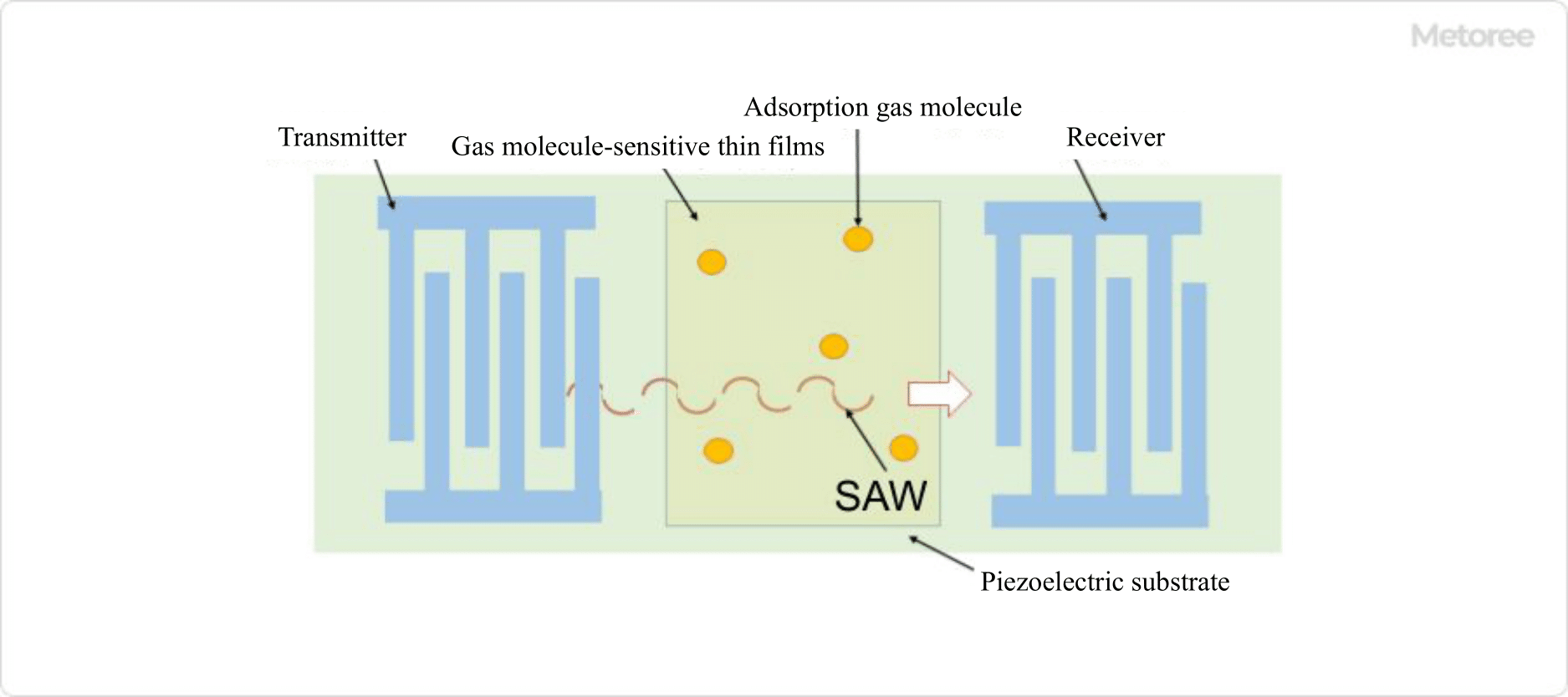

Figure 2. Configuration of the gas sensor using the SAW element

As shown in Figure 2, a thin film sensitive to gas molecules is formed between two IDTs on a substrate. The SAW frequency, amplitude, and other characteristics of the SAW when gas molecules are adsorbed on the thin film can be used to determine the amount of gas adsorbed. The type of gas can be identified by the material of the thin film. In the case of hydrogen, Pd or Pd-Ni alloy is used.

5. Application to Touch Panels

Ultra-super SAW touch panels detect the position of the display when touched by a finger using the attenuation of the ultra-super SAW.

Two IDTs placed at the four corners of the glass substrate emit SAW waves that are transmitted as vibrations to the surface of the panel and received by the two IDTs on the opposite side. When a finger touches the screen, the super cardioid surface elastic wave attenuates, and the position on the touch panel can be identified by detecting the amplitude change in the receiver device.

6. Application to Improve Radiation Resistance of Computers

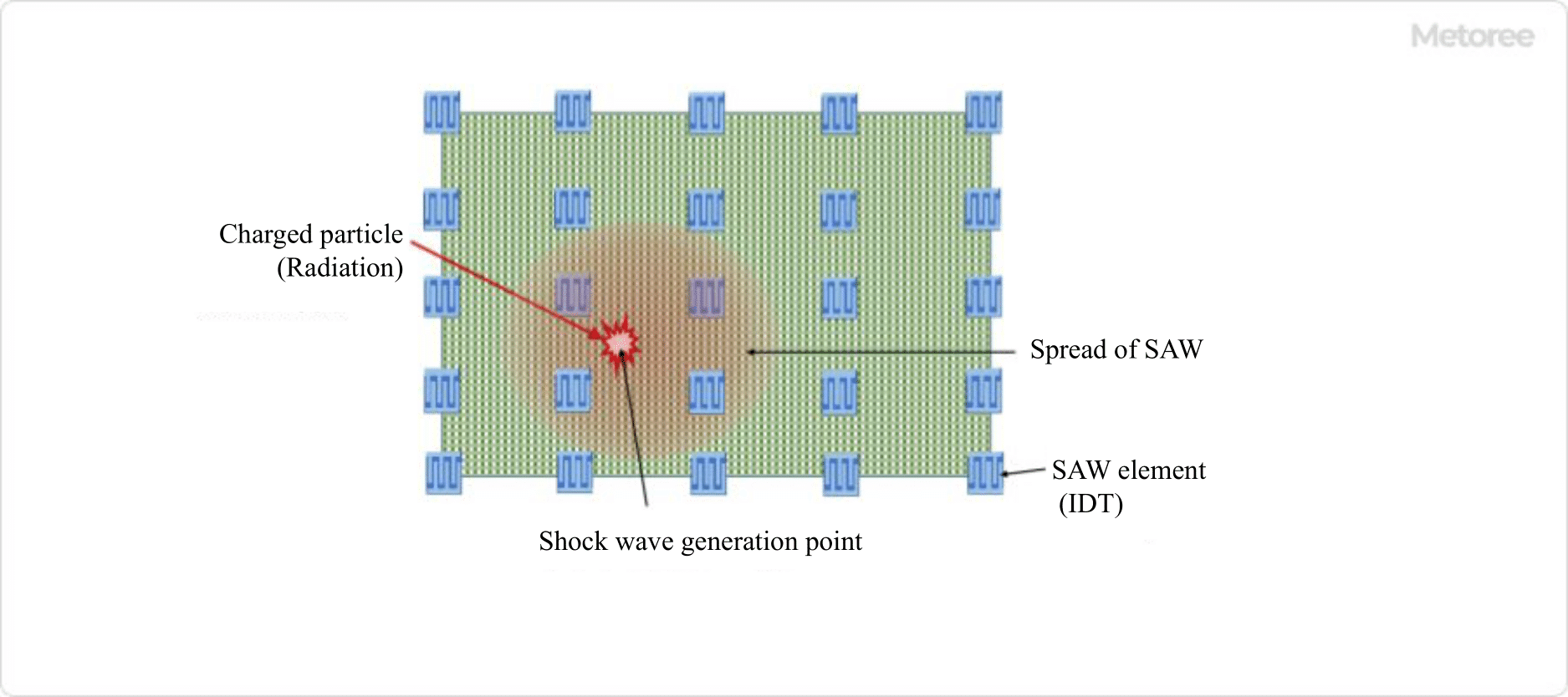

Figure 3. Example application in a computer (L1 cache)

As shown in Figure 3, 5 x 5 SAW elements are placed on the L1 cache memory (about 256kB) for high-speed data exchange with the CPU of a computer. The location of the occurrence of a phenomenon that inverts the memory data when charged particles are injected into a radiation environment such as outer space (soft error), can be calculated from the time difference in the arrival of the shock wave signals to the 25 SAW elements. 7.

7. Application to Quantum Computers

To realize a practical quantum computer, it is necessary to integrate qubits (the smallest unit of quantum information) to a high degree of integration. When a time-varying high-frequency voltage is applied to a specially structured comb-shaped electrode “chirped IDT,” a surface acoustic wave with a wide bandwidth is generated.

By placing a single electron on a SAW isolated pulse formed by superimposing in-phase surface acoustic waves and canceling out unwanted waves, a quantum bit can be transferred.

Other Information on SAW (Surface Acoustic wave)

About Piezoelectric Materials

Piezoelectric materials, which can be used for both sensor and actuator functions, are broadly classified into piezoelectric single crystals, piezoelectric thin films, and piezoelectric ceramics. Single crystals are characterized by low propagation loss and can be used over a wide frequency range. In particular, only single crystals are used for high-frequency materials.

When piezoelectric single-crystal materials were first developed, quartz, lithium niobate (LiNbO3: LN) single-crystals, and lithium tantalate (LiTaO3: LT) were used. Currently, the development of compound single crystals with perovskite-type crystal structures characteristic of transition metal compounds consisting of ternary systems, such as zinc/lead niobate/lead titanate solid solution (PZNT) and magnesium/lead niobate/lead titanate solid solution (PMZT), is underway.

Piezoelectric ceramics have advantages in that they can produce SAW with large amplitude, can be easily mass-produced, and are relatively stable because they are oxides; PZT and BaTiO3 are examples.

To prevent elastic waves from leaking onto the substrate and damaging the SAW characteristics, piezoelectric materials are being made thinner. For example, this can be achieved by forming a thin film of piezoelectric single-crystal material on top of a layer with high sound velocity. Piezoelectric thin film materials include ZnO, AIN / ScAIN, KNN, and PLA.