What Is a Color Illuminance Meter?

A color illuminance meter is an instrument used to measure the color and brightness of light.

It combines the function of a color illuminance meter, which measures the brightness of light, with the function of measuring the color of light. A color illuminance meter measures the intensity of light emitted from a light source per unit area and displays it in lux.

The color of the light is displayed by analyzing the wavelength of the light and measuring the spectral characteristics and color temperature of the light-emitting substance.

Uses of Color Illuminance Meters

Color Illuminance Meters are widely used for light quality control and design/adjustment in lighting and display devices.

Specific applications include:

1. Lighting Design

It is used in lighting design for buildings, stores, and offices to measure light intensity, color temperature, and color gamut, and to propose appropriate lighting. It is also useful in evaluating the performance of existing lighting equipment and planning for retrofits.

2. Product Evaluation

It is used to evaluate and improve light performance in the development of lighting fixtures, displays, and other products. It can evaluate the color reproducibility, uniformity, and brightness consistency of a product.

3. Color Management

It is used to ensure accurate color reproduction in color management for printing and painting. By quantifying color differences and matching them to specified values, consistent quality can be maintained.

4. Health/Safety Management

It is also used to measure the impact of light on health. For example, improper light intensity or color temperature can cause problems, such as eyestrain and sleep disorders. In addition, proper lighting environments must be ensured in safety management at factories and construction sites.

5. Research and Development

In research and development related to light, it is used to evaluate the characteristics of light and light sources. For example, in the development of LEDs, it is important to check the uniformity of color temperature and color gamut. It is also used in the development of medical devices and sensing technologies that utilize light.

Principle of Color Illuminance Meters

The color illuminance meter consists mainly of a light-receiving part and an arithmetic part.

1. Light-Receiving Part

The photodetector is a light-sensing sensor that consists of an optical filter that transmits light in a specific wavelength range, a silicon photodiode (SiPD) as a light-receiving element, and a circuit that amplifies the output current. The light receiving part is usually equipped with a sensor that combines three optical filters and a light receiving element, each of which is sensitive to red, blue, and green, respectively, and is configured to transmit the output signal to an arithmetic unit.

2. Arithmetic Section

The calculation section calculates and displays the brightness and color of light based on the signals from the light receiving section. If the light-receiving part has three sensors with sensitivity in the red, green, and blue regions, the light intensity and color can be calculated from the magnitude of each sensor’s signal.

Furthermore, since the color illuminance meter must numerically evaluate the color as seen by the human eye, the computing section adjusts the sensitivity so that the sensitivity to each wavelength of visible light matches that of the human eye.

3. Other

Color thermometers and spectral distribution meters spectrally measure the wavelength distribution of light and calculate the color temperature and color gamut, which represent the color of light, based on this information.

Types of Color Illuminance Meter

Color illuminance meters are instruments used to measure light intensity and color information. There are different types of color illuminance meters, but the typical types are as follows:

1. Spectroradiometer

Spectroradiometers measure the wavelength spectrum of light. It evaluates the intensity of light at each wavelength and analyzes the color and spectral distribution from the results. It is used for advanced color measurement and color consulting.

2. Color Thermometer

A color thermometer measures the color temperature of a light source. Color temperature is a measure of the hue of light expressed in Kelvin (K). It is used to adjust the color of lighting environments and in fields such as photography and video production.

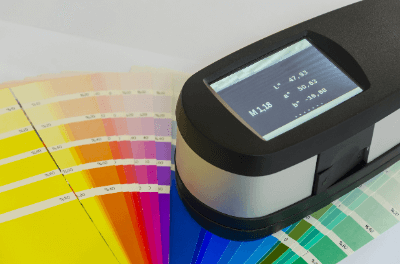

3. Colorimeter

A colorimeter evaluates the color difference between a measured color and a standard color. The color difference is an indicator of color differences and is expressed as a numerical value, such as ΔE. They are used in quality control, manufacturing, and printing industries to help ensure color consistency and accuracy.

While these are common types of color illuminance meters, there are actually a variety of products that combine a variety of special features and applications. It is important to select the best color illuminance meter based on your specific application and requirements.

More Color Illuminance Meter Information

Notes on the Use of Color Illuminance Meters

Since color illuminance meters evaluate color based on the intensity of light hitting the light-sensitive area, the way the light hits the light-sensitive area is important. Specifically, the angle at which the light strikes and the distance from the light source are important.

The silicon photodiode is located at the back of the photosensitive area, so if light enters the photosensitive area at an angle, the light hitting the photosensitive area will be biased and the measured values will be distorted. Install the diode in such a way that the light incident is perpendicular to the light receiving section.

Also, since illuminance is inversely proportional to the square of the distance from the light source, measuring at a distance from the light source will result in a relatively large error due to weak light. If the light source is too close, the light-receiving part will be saturated, and accurate measurement will not be possible.

Although it depends on the intensity (brightness) of the light source, it is generally advisable to measure at a distance of about 1 meter.