What Is an Optical Measuring Machine?

An optical measuring machine is an instrument that mainly uses photodetectors to measure light. They are used to process light waves and other signals to make images more visible and to analyze their characteristics.

An optical measuring machine is an instrument that mainly uses photodetectors to measure light. They are used to process light waves and other signals to make images more visible and to analyze their characteristics.

Optical measuring machines generally include illuminance meters, luminance meters, radiometers, and integrating spheres. Depending on the instrument, these can be combined to measure optical characteristics such as transmission and reflection with high precision. There are also optical measuring machines capable of three-dimensional measurements.

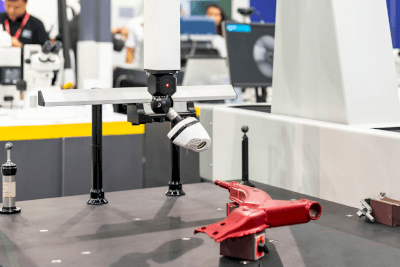

These optical three-dimensional measuring instruments are non-contact measuring instruments that use images to perform measurements, similar to optical comparators and measuring microscopes.

Uses of Optical Measuring Machines

Optical measuring machines are used for various purposes.

For example, illuminance meters, also called UV illuminance meters or UV intensity meters, are used for sealing electronic components and printing printed circuit boards. Most are used to control the intensity of lamps used in sterilization processes in various industries.

Other uses of optical measuring machines include integrating spheres, of which the typical integrating sphere is the spherical luminous flux meter.

The spherical luminous flux meter is used for comparative measurement of the total luminous flux of lamps. It is a small integrating sphere used for measuring spectral reflectance attached to spectrophotometers. It is also commercialized as a portable measuring instrument and can be carried around.

However, large-size integrating spheres are also available, so care should be taken when considering their introduction.

The uses of integrating spheres are mainly to measure the total luminous flux of light sources, such as fluorescent lamps, incandescent lamps, and backlights of mobile devices.

Principle of Optical Measuring Machines

Since optical measuring machines are classified according to all kinds of equipment and measurement methods, the principles of illuminance meters and integrating spheres described in the article are explained in this topic.

UV Illuminance Meter

In general, UV illuminance meters are small and portable instruments. They have a simple structure, with a UV-transmitting filter and a visible-absorbing filter in front of the silicon photodiode, which absorbs visible light and other wavelengths, extracting only the UV light.

Interchangeable photodetectors are also available, and by replacing the photodetector, they can be used for various uses of UV light, such as UV curing and UV cleaning.

Integrating Sphere

There are various types of integrating spheres depending on the measurement method and uses of the sphere. The main types of use include beam measurement, total luminous flux measurement, uniform standard light source method, and transmittance/reflectance measurement methods.

A typical integrating sphere collects light, makes it uniform by multiple reflections within a space, and detects a portion of the light. The space’s interior is spherical, and the inner walls are made of highly reflective materials such as barium sulfate, thermoplastic resin, or gold plating.

The integrating sphere has a hole at the position where the measurement light is irradiated, and the incident light is reflected inside the sphere.

However, repeated diffuse reflection is necessary for uniformity of light. Therefore, the emitted light mustn’t directly hit the detector.

Therefore, a light shielding plate for diffusion, known as a baffle, is installed between the light source and the detector.

Global Market for Optical Measuring Machines

- Presentation by Kenneth Research

A market study by Kenneth Research projects that the global optical imaging equipment market will reach US$2.3 billion in 2022 and US$6.1 billion by the end of FY2030.The market is expected to expand at a compound annual growth rate (CAGR) of approximately 15% during the forecast period 2022-2030.