What Is a Cooled CCD Camera?

A Cooled CCD Camera is a digital camera with a cooled CCD (Charge Coupled Device) sensor as the light receiving element.

Also called a “charge-coupled device,” a CCD is a type of image sensor; CCDs are used to convert light energy into an electrical charge, which is then captured as image data. In particular, they are often used in photography, video production, astronomy, and other fields.

A CCD camera has a large number of light sensors (pixels) arranged on a light-receiving surface, each of which produces an electric charge corresponding to the intensity of the light. These charges are read back as analog signals and converted to digital signals, allowing CCD cameras to achieve high image resolution, dynamic range, and low noise performance.

They are also excellent for capturing images in the dark and detecting weak light sources. However, CCD cameras are relatively sensitive to light, and noise increases with longer exposures.

Uses of Cooled CCD Cameras

Cooled CCD Cameras are mostly used for photography (where images are obtained as digital signals through the light receiving element) when connected to a PC, or for photography requiring long exposures such as astrophotography due to the noise reduction caused by cooling.

In the research field, it is also used for DNA analysis and spectroscopic analysis. It is also used to detect (photograph) faint chemiluminescence, which requires signal integration through long exposures, and to capture luminescence imaging images in combination with electron microscopes and optical microscopes, taking advantage of the CCD’s multichannel detector aspect.

Principle of Cooled CCD Camera

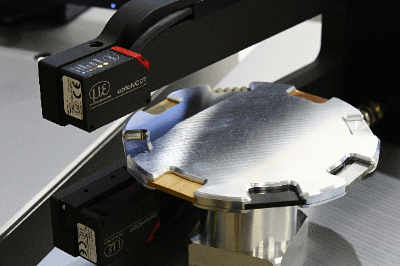

A Cooled CCD Camera uses a Peltier element to cool the CCD to enable long exposures, and a CCD camera uses an image sensor (photosensor) to accumulate an electrical charge from external light, which is converted to an electrical signal by an A/D converter to obtain a digital image.

When used at room temperature, a phenomenon called “dark current” occurs even when the camera is not receiving light, and this is a major cause of noise. This is not a problem for normal photography with exposures of only a few seconds or so, but for long-exposure photography, the noise caused by this dark current can have a significant impact.

Since photography and management of the cooling temperature is performed by a PC with dedicated software installed, a connection to a PC is essential when taking pictures with a Cooled CCD Camera. Because of its ability to reduce noise, a cooled CCD camera is useful for astronomical photography with long exposures with the shutter open, and for chemiluminescence detection photography, in which faint luminescence is detected by accumulating signals through long exposures.

How to Select a Cooled CCD Camera

1. Resolution

Resolution is an important factor that indicates the detail and accuracy of an image. The resolution to choose depends on the application and purpose of use.

Higher resolution is suitable for observing minute objects and detailed structures, but it also affects file size and processing speed, so it should be adjusted according to the purpose and application.

2. Pixel Size

Pixel size indicates the physical size of an individual pixel. The larger the pixel size, the higher the sensitivity, but the resolution is generally lower. The appropriate pixel size depends on the characteristics of the object being observed and the shooting conditions.

3. Noise Level

Noise is a factor that directly affects image quality. Cooled CCD Cameras can reduce noise by cooling the sensor, but noise levels vary among models and manufacturers. Noise level is especially important for dark or low-light conditions.

4. Operating Speed

Operating speed indicates the speed of image acquisition and data transfer. High operating speeds are required for continuous shooting and fast imaging applications. It is important to check the frame rate and data transfer rate of the camera and select the appropriate speed for the intended use.

5. Cooling Capacity

Cooled CCD Cameras are equipped with a cooling system to cool the sensor. Cooling capacity is important to maintain a constant sensor temperature. Check the efficiency of the cooling system and the range of cooling temperatures to select the appropriate cooling capacity for the environment and application in which it will be used.

6. Interfaces and Compatibility

In order to use a Cooled CCD Camera, an interface that allows data to be exchanged between the camera and a computer or control unit is required. Common interfaces include USB, FireWire, and Gigabit Ethernet. It is important to check compatibility with the system to be used and select an appropriate interface.

Other Information on Cooled CCD Cameras

In recent years, more and more cameras are replacing CCD cameras with CMOS (Complementary Metal-Oxide-Semiconductor) sensors, which are less expensive, more energy efficient, and offer faster data readout.

However, with the exception of some specialized applications, they can be inferior to CCD cameras in terms of image quality and sensitivity.

A suction lifter is a device that uses the suction properties of rubber or other materials to adhere temporarily to an object.

A suction lifter is a device that uses the suction properties of rubber or other materials to adhere temporarily to an object.

Laser distance meters are used for non-contact, high-precision distance measurement using laser light.

Laser distance meters are used for non-contact, high-precision distance measurement using laser light.