What Is Semiconductor Lithography Equipment?

Semiconductor Lithography Equipment is used to depict circuit patterns on silicon wafers in the semiconductor manufacturing process. A powerful ultraviolet light is transmitted through a photomask, which serves as a prototype for the circuit pattern, and the circuit pattern is transferred onto a silicon wafer coated with photoresist. In recent years, some equipment uses a laser with a wavelength of 13 nm, called EUV, to miniaturize fine circuit patterns. Since extremely high precision is required for positioning, etc., the equipment is expensive.

Applications of Semiconductor Lithography Equipment

Semiconductor Lithography Equipment is used in the exposure process of manufacturing integrated circuits (ICs), which include semiconductor devices such as MOS (metal oxide semiconductor)-FETs (field effect transistors).

In the IC manufacturing process, photolithography and etching cycles are repeated sequentially on a silicon wafer to stack and process layers (layers) of silicon oxides and metals in a predetermined pattern, which are processed to have the characteristics required for semiconductor devices. In the case of n-type MOS (NMOS), for example, an n-type (n+ type) MOS is formed by forming a silicon oxide film in the gate region on a p-type silicon substrate and a gate metal on top of it, and ion implanting high concentration impurities in the drain and source regions. Each of the photolithography and etching steps in this series of processes is configured as shown in the figure (film deposition process S1~resist stripping process S6).

Of these, the exposure process (S3) is the process performed using Semiconductor Lithography Equipment. Different wavelengths of exposure equipment are used depending on the dimensions of the circuit pattern and the accuracy of the Semiconductor Lithography Equipment.

Principle of Semiconductor Lithography Equipment

Semiconductor Lithography Equipment consists of a light source, condenser lens, photomask, projection lens, and stage. Ultraviolet light generated from the light source is adjusted by the condenser lens so that they face the same direction. The ultraviolet light then passes through a photomask, which serves as a prototype for one layer of the circuit pattern, and the light is reduced by the projection lens to transfer the circuit pattern (one layer of the circuit pattern) of the semiconductor device onto the silicon wafer. In an exposure system such as a stepper, once the transcription is completed, the silicon wafer is moved by the stage and the same circuit pattern is transferred to another position on the silicon wafer. By replacing the photomask, another layer of the circuit pattern of the semiconductor device can be transferred.

KrF excimer lasers with a wavelength of 248 nm, ArF excimer lasers with a wavelength of 193 nm, and EUV light sources with a wavelength of 13 nm are used as light sources.

The design rule (minimum processing dimension) for the latest semiconductor manufacturing process has been miniaturized to 3 to 5 nm, so high precision on the nanometer scale is required for all condenser lenses, photomasks, projection lenses, and stages. Also, because of the progress of stacking, exposure is performed several times before a single semiconductor is produced by changing the circuit pattern.

Semiconductor Lithography Equipment Market Size and Share

The global electronics market continues to expand, and the semiconductor industry is becoming increasingly important in supporting this expansion. The global semiconductor market experienced negative growth in 2019, but has continued to expand in the past despite experiencing the Lehman Shock and other problems. In recent years, memory technology development has shifted from miniaturization to 3D, and etching technology has become more important.

The Semiconductor Lithography Equipment market size is 1.852 trillion yen as of 2018.

The market share by consumption region is as follows: 1st South Korea 36%, 2nd Taiwan 19%, 3rd China 18%, 4th US 14%, and 5th Japan 7%. Semiconductor Lithography Equipment vendor share by nationality (2018) is almost oligopolized by Europe and Japan, with Europe (84%), Japan (14%), and the United States (2%).

About EUV Lithography Equipment

EUV (Extreme Ultraviolet) Lithography Equipment is Semiconductor Lithography Equipment that uses extremely short wavelength light called Extreme Ultraviolet Light. It enables processing of finer dimensions that are difficult to process with conventional exposure systems using ArF excimer laser light.

Semiconductor manufacturing has been progressively miniaturized in accordance with Moore’s Law (semiconductor integrated circuits become four times more highly integrated and functional in three years). The development of reduced projection exposure technology called steppers, shorter exposure wavelengths, and immersion exposure technology has dramatically improved resolution.

Miniaturization means that the minimum process size that can be burned onto a wafer becomes smaller, and the minimum process size R is expressed by the following Rayleigh’s formula.

R = k/λ/NA *k is a proportionality constant, λ is the exposure wavelength, and N.A. is the numerical aperture of the exposure optical system.

Various technological developments have enabled miniaturization by making k smaller, λ smaller, and NA larger.

EUV lithography systems are considered to be a technology that can break through the limitations of the past by shortening the exposure wavelength, and they have been mass-produced in recent years.

Prices of Semiconductor Lithography Equipment

Semiconductor Lithography Equipment is indispensable for the efficient mass production of semiconductors.

The shorter the wavelength of the light source used in Semiconductor Lithography Equipment, the finer the pattern can be formed and the more expensive the exposure equipment becomes. For each wavelength, i-line lithography costs about 400 million yen, KrF about 1.3 billion yen, ArF dry about 2 billion yen, ArF immersion about 6 billion yen, and EUV about 20 billion yen.

The finer the circuit, the faster the signal transmission and the more energy efficient it can be, but in recent years, the increase in process cost due to miniaturization, including the price of Semiconductor Lithography Equipment, has become impossible to ignore.

In addition, the throughput of Semiconductor Lithography Equipment is also an important indicator of the required performance from the standpoint of semiconductor manufacturing costs. Throughput is a performance indicator of how fast a circuit pattern can be exposed, and as throughput increases, the production cost (running cost) per silicon die decreases. It is considered important during the mass production of semiconductor chips.

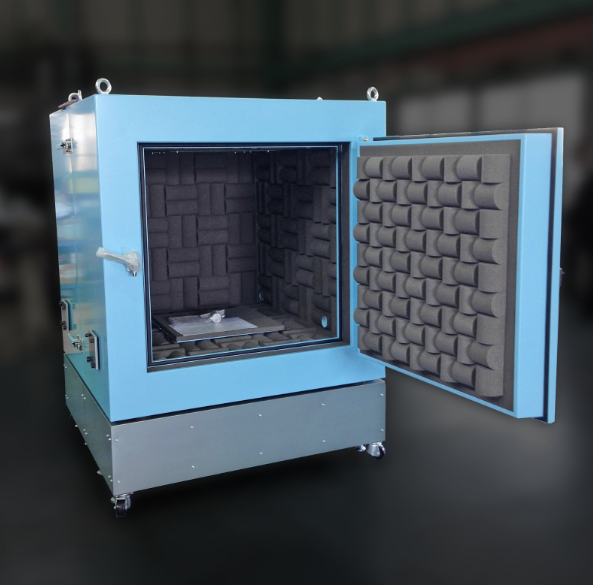

An anechoic box has two properties: sound insulation and sound absorption.

An anechoic box has two properties: sound insulation and sound absorption. Un sensor de temperatura es un dispositivo de control con un sensor para medir la temperatura ambiente y una función para suministrar energía.

Un sensor de temperatura es un dispositivo de control con un sensor para medir la temperatura ambiente y una función para suministrar energía. A noise-cut transformer is a device designed to prevent noise interference. It is a trademark developed by DENKEN SEIKI KOGYO K.K. in 1960 and is also called Isolation Transformers, although its common names are fault wave isolation transformers and transformers for noise suppression. Noise-cut transformers are a practical application of transformer-type noise prevention elements.

A noise-cut transformer is a device designed to prevent noise interference. It is a trademark developed by DENKEN SEIKI KOGYO K.K. in 1960 and is also called Isolation Transformers, although its common names are fault wave isolation transformers and transformers for noise suppression. Noise-cut transformers are a practical application of transformer-type noise prevention elements.