What Is a Linear Guide Rail?

A linear guide rail is a rail-like structure used to attach sensors or other devices, commonly found in industrial and automation applications. These rails feature holes or slots for easy mounting and are known for their ease of replacement and maintenance. Wiring can be conveniently routed along the rails for a cleaner appearance.

Linear guide rails adhere to standardized specifications, allowing compatibility with a wide range of manufacturers and devices. It is important to consider the electrical characteristics and requirements of the devices being mounted, including proper isolation and grounding.

Uses of Linear Guide Rails

Linear guide rails have diverse applications:

1. Industry

Used in automation and control systems, linear guide rails support the installation of various sensors and devices. In production lines, they can hold position and temperature sensors for process monitoring and control. These devices work in conjunction with controllers to facilitate automated processes.

2. Security

Linear guide rails play a crucial role in security systems, supporting equipment like surveillance cameras. They also mount motion sensors and door access controls, enhancing security by detecting unauthorized entry or movement.

3. Building Management Systems

In building management systems, linear guide rails are used for environmental monitoring. They support lighting and light sensors in lighting control systems and can hold temperature and humidity sensors for maintaining comfortable environments and improving energy efficiency.

Principle of Linear Guide Rails

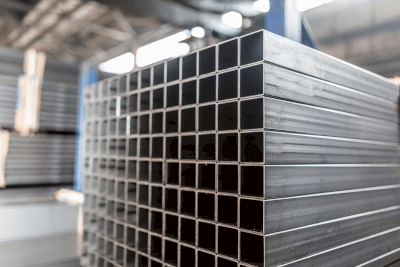

Linear guide rails provide a standardized structure for positioning sensors and devices. They are typically made from lightweight and cost-effective materials like aluminum, although stainless steel is preferred for corrosion resistance. Rails can be cut to required lengths and feature holes or slots for mounting sensors or devices.

Types of Linear Guide Rails

Various types of linear guide rails include:

1. Flange Parallel Type

This type has a parallel flange at the top, providing space for sensor mounting, and is suitable for horizontal placements.

2. Orthogonal Flange Type

Featuring a flange protruding at a right angle at the top, this type is used for perpendicular mounting, useful in tight spaces or complex arrangements.

3. Straight Type

A straight rail without a top flange, this type is ideal for simple, straight-line arrangements or when a high density of sensors and devices is required.

A metal square tube is a general term for

A metal square tube is a general term for