What Is a Whitworth Screw?

Invented in England in 1841 by Whitworth, the Whitworth screw is distinguished by its 55-degree thread angle and triangular threads. As the first standardized screw type, it’s expressed in inches and marked with the symbol “W.”

Usage of Whitworth Screws

Whitworth screws are integral to the waterworks and construction industries, where precision and reliability in fastening are paramount. Their design ensures higher accuracy and durability, making them suitable for applications demanding tight tolerances.

Characteristics of Whitworth Screws

These screws feature a unique 55-degree thread angle, differing from the 60° angle commonly found in metric and other inch screws. Their dimensions, including the outer diameter and thread pitch, are measured in inches, catering to specific engineering and manufacturing requirements.

Material and Surface Treatments

Materials for Whitworth screws vary, with selection crucial for ensuring strength and safety in critical applications. Protection against electrical corrosion is important, particularly when combining different metals like aluminum and stainless steel. Surface treatments are chosen based on corrosion resistance, aesthetic quality, and cost considerations.

Proper Use and Preventing Loosening

Proper use of Whitworth screws involves ensuring the tightening force and repetitive forces like vibration are within safe limits. It’s essential to prevent damage to the fastened objects and the screws themselves. Preventative measures against loosening include using loosening adhesives, double nuts, and specifically designed products to maintain the integrity of fastened objects, particularly in applications where safety is critical.

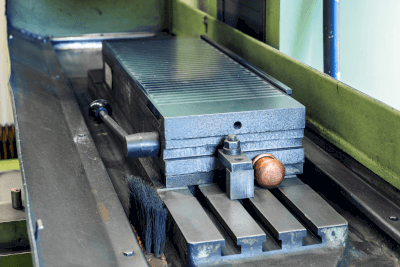

A straight reamer is a type of blade used in reaming, a process for high-precision hole finishing. It is similar to a

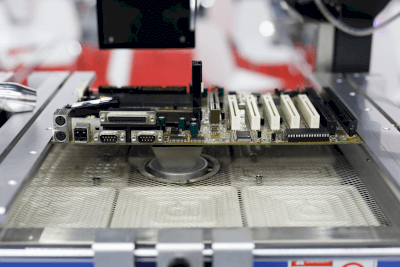

A straight reamer is a type of blade used in reaming, a process for high-precision hole finishing. It is similar to a  An electric lifting device is an apparatus powered by electricity that can raise, lower, and adjust the height of objects such as tables, chairs, and beds.

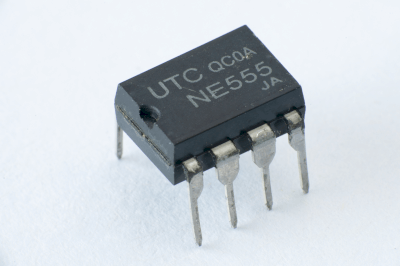

An electric lifting device is an apparatus powered by electricity that can raise, lower, and adjust the height of objects such as tables, chairs, and beds. A 555 timer IC is commonly used as an

A 555 timer IC is commonly used as an