What Is an Electric Chain Hoist?

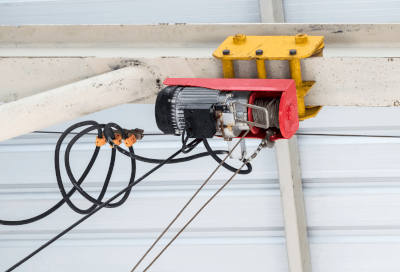

An electric chain hoist is a lifting device that utilizes an electric motor to raise heavy loads. Unlike manual hoists, electric chain hoists provide powered assistance, making them suitable for heavier or more frequent lifting tasks. Typically, these hoists are mounted to the ceiling or used alongside tripods or cranes. While they primarily lift and lower loads, when paired with overhead or gantry cranes, they can also facilitate horizontal load movement.

An electric chain hoist is a lifting device that utilizes an electric motor to raise heavy loads. Unlike manual hoists, electric chain hoists provide powered assistance, making them suitable for heavier or more frequent lifting tasks. Typically, these hoists are mounted to the ceiling or used alongside tripods or cranes. While they primarily lift and lower loads, when paired with overhead or gantry cranes, they can also facilitate horizontal load movement.

Uses of Electric Chain Hoists

Electric chain hoists are versatile and used in various settings where heavy lifting is required. They can facilitate the safe loading and unloading of heavy items from trucks in confined spaces using a simple tripod setup. At demolition sites, they’re employed to extract foundations or remove large tree roots due to their portability. A lever block, a smaller and more compact version of the chain block, is also commonly used in similar applications.

Principle of Electric Chain Hoists

Manual chain hoists operate using a combination of pulleys, a principle familiar to many from school physics. These devices feature a ring-shaped chain integrated with a toothed combination pulley. Pulling the chain manually enables the lifting of heavy objects with human effort.

Electric chain hoists, in contrast, employ an electric motor and multiple gears to generate the necessary torque for lifting. Generally, they have a lower lifting capacity than their manual counterparts of similar size. Due to their heavier weight and the need for a power supply, electric chain hoists are less suited for mobile applications and are ideal for factory use with gantry cranes and other equipment. Despite being motorized, many models are designed to be dustproof, waterproof, and durable for outdoor use.

A thickness gauge is a precision instrument used to measure the thickness of various materials. It typically employs a

A thickness gauge is a precision instrument used to measure the thickness of various materials. It typically employs a

A flag hinge is a metal

A flag hinge is a metal  A container dolly, also known as a

A container dolly, also known as a  A hardcase, also known as a protector tool case, is a durable and airtight container typically made of resin, designed for storing and transporting precision instruments and tools. These cases are equipped with a cushion on both the top and bottom, a lockable lid, and a handle for easy carrying. Hardcases vary in specifications, including features like waterproofing, drip-proofing, air pressure adjustment, and shock resistance, making it important to select one based on the specific intended use.

A hardcase, also known as a protector tool case, is a durable and airtight container typically made of resin, designed for storing and transporting precision instruments and tools. These cases are equipped with a cushion on both the top and bottom, a lockable lid, and a handle for easy carrying. Hardcases vary in specifications, including features like waterproofing, drip-proofing, air pressure adjustment, and shock resistance, making it important to select one based on the specific intended use. A battery spring is a contact terminal designed to supply electricity from batteries in devices like battery boxes that use dry-cell batteries. There are two main types: wire springs and plate springs. Plate springs are further categorized into those with a wire spring for the negative pole and others with plate springs for both poles. These springs are standardized for each battery size in terms of contact area and terminal height, typically made from materials like nickel-plated

A battery spring is a contact terminal designed to supply electricity from batteries in devices like battery boxes that use dry-cell batteries. There are two main types: wire springs and plate springs. Plate springs are further categorized into those with a wire spring for the negative pole and others with plate springs for both poles. These springs are standardized for each battery size in terms of contact area and terminal height, typically made from materials like nickel-plated