What Is Tungsten Machining?

Tungsten machining refers to the processing of tungsten, a metal known for its high melting point and hardness. This metal’s name is derived from the Swedish word for heavy stone. It exhibits a silver-gray color and is characterized by metallic stability and high electrical resistance. Tungsten’s exceptional heat resistance makes it ideal for ultra-high temperature applications, such as in heat treatment furnaces, while its low thermal expansion and high shape stability at extreme temperatures are noteworthy.

Uses of Tungsten Machining

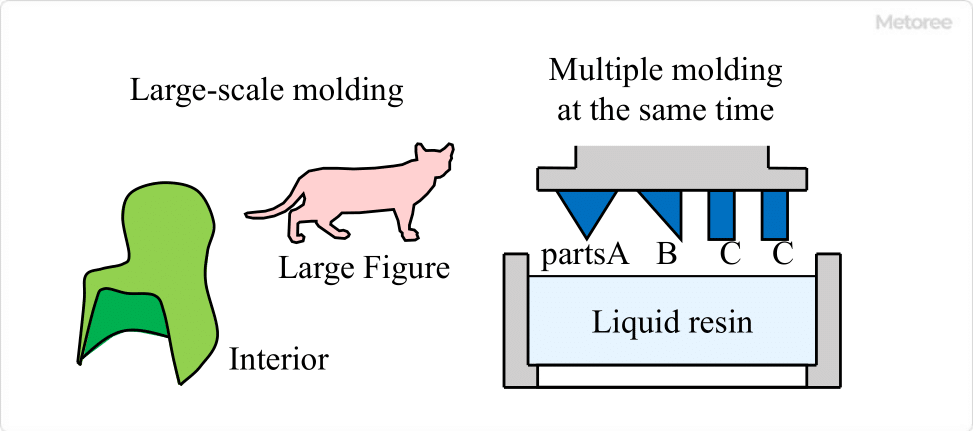

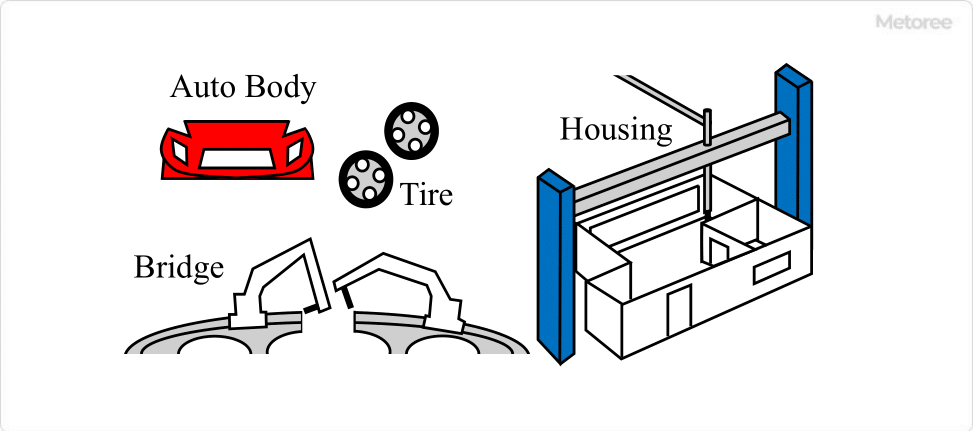

Machining tungsten is crucial in industries requiring mechanical stability, including industrial and medical sectors. Despite the challenges posed by its hardness, tungsten’s applications range from electromagnetic wave sources in microwave ovens to weights in fishing and sports equipment, and its radiation shielding properties are valuable in medical devices. Though once common in incandescent light bulb filaments, tungsten has largely been supplanted by LEDs.

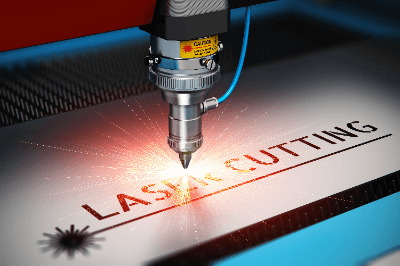

Types of Tungsten Machining

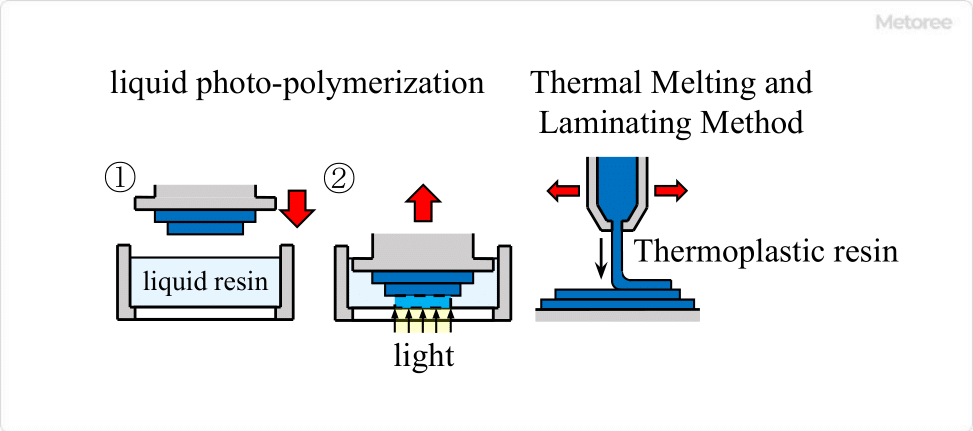

Machining methods for tungsten include turning, milling, and tapping, each with specific considerations:

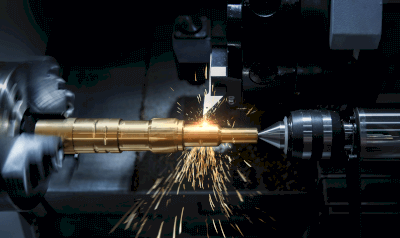

1. Lathe Turning

Surface roughness in lathe turning varies with the insert material. Cermet inserts, known for their larger rake angle and lower cutting resistance, produce finer finishes, whereas cemented carbide inserts, with their smaller rake angles, result in rougher textures due to thicker chip formation and higher resistance.

2. Milling

For milling, a combination of wet roughing to reduce speed and dry finishing ensures stable surface quality, as wet finishing can lead to inconsistencies.

3. Tapping

Tapping a challenging material such as tungsten requires careful control of the feed rate to prevent tap breakage, with planetary cutters recommended after initial drilling to shorten machining time.

How to Select Tungsten Machining

Selection criteria for machining tungsten involve choosing the appropriate tools and processes to mitigate its inherent processing challenges. Recommendations include using cermet inserts for smoother lathe turning surfaces, wet roughing and dry finishing in milling for optimal surface quality, and employing planetary cutters for efficient tapping.

Structure of Tungsten Machining

Tungsten, symbolized as W and with an atomic number of 74, boasts the highest melting point among metals at 6,192 °F (3,422 °C) and the lowest coefficient of thermal expansion. Its density, comparable to gold, and superior radiation shielding capabilities make it preferable to lead in medical and industrial applications. Tungsten’s combination with carbon forms tungsten carbide (WC), a compound with a Mohs hardness of 9, extensively used in cutting tools for its exceptional hardness.