What Is an Earth Clamp?

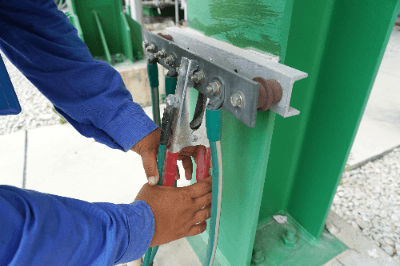

An Earth Clamp is a type of tool used in electrical and welding works, serving as a grounding clamp.

Electrical circuits must be grounded for safety. By using an Earth Clamp, the entire electrical circuit is grounded, preventing electrical leakage and electric shock accidents.

The clamp is also made of metal and is sturdy, so it can be used for a long period of time. However, they are often subjected to bending and other forces, which may cause them to deteriorate and break.

Regular inspection and replacement are necessary because use of a broken wire can cause electrical leakage and electric shock accidents.

Uses of Earth Clamps

Earth Clamp is one of the tools used in work. It is widely used mainly for work related to electricity. The following are some examples of uses for Earth Clamps:

1. Electrical Work

In electrical work involving high-voltage or higher, grounding of the electrical circuit is necessary to discharge residual electric charges and ensure safety. By using an Earth Clamp, grounding work can be performed efficiently and safely.

2. Welding Work

In welding work, a strong electric current is applied when metals are joined together. The use of an Earth Clamp can prevent electrical leakage and electric shock accidents.

3. Geological Survey

Geological surveys sometimes measure the electrical properties of underground rocks and soil. Earth Clamp can be used to ground the measurement device.

4. Ground Improvement Work

During ground improvement work, electrodes may be installed in the ground. The electrode is embedded in the ground using an Earth Clamp.

5. Electromagnetic Wave Measurement

Electromagnetic wave measurement requires a reference ground potential in order to measure ground-to-ground voltage. By using an Earth Clamp, the measurement device is grounded to the ground and the ground potential is detected.

Principle of Earth Clamp

An Earth Clamp consists of a main unit and wiring.

1. Main Unit

The main body part is a clamp for clamping the target metal part. If the clamp is an alligator type, it has a handle to open and close the clamp by gripping the handle. If the clamp part is a vise, the clamp is opened and closed by turning the handle.

2. Wiring

The wiring section is divided into a wire section and a sheathed section. The material of the wire is generally copper conductor. Copper is often used for electrical wiring because of its high electrical conductivity, corrosion resistance, and heat resistance. In addition, wires for Earth Clamp are often twisted together because of the durability required.

3. Sheathing

Insulating materials such as PVC (polyvinyl chloride) or rubber are generally used, although the sheathing may be omitted. The sheath material prevents direct contact between the clamp body and the wire, thereby preventing electrical leakage and electric shock.

PVC is widely used in general because of its high durability and excellent weather resistance. Rubber is ideal for use as moving wires because of its excellent oil and abrasion resistance. However, it deteriorates due to ultraviolet rays and oxygen, so periodic replacement is necessary.

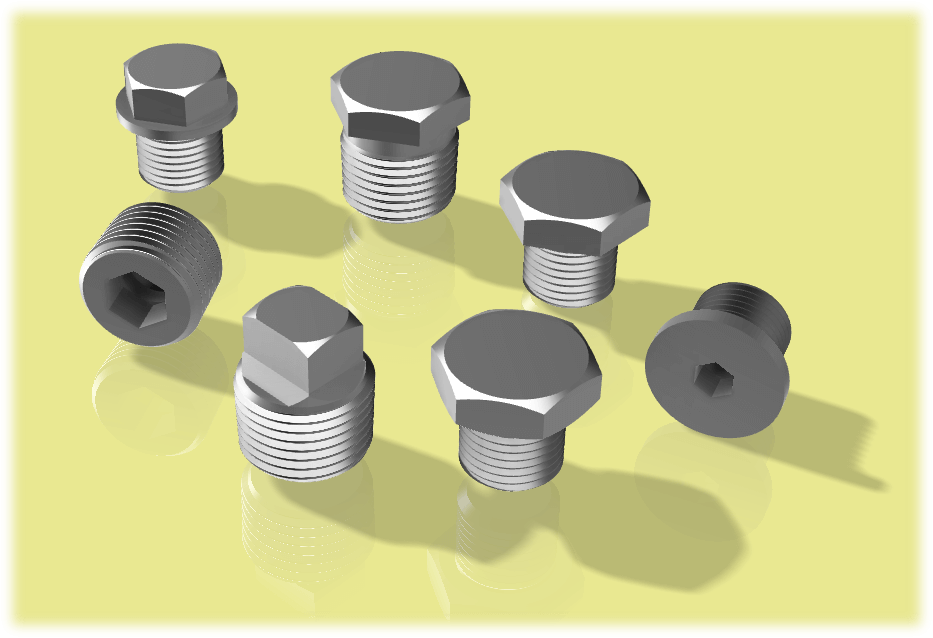

Types of Earth Clamps

Earth Clamps are available in the following types, depending on the material of the clamp part:

1. Pinch-Type Earth Clamp

Pinch-type clamps are used to clamp a metal part to be worked on. They are characterized by their high versatility, as they can be adjusted to fit the shape of the work object. They are widely used in electrical work and welding operations.

2. Vise-Type Earth Clamp

This is a vise-type clamp that can firmly hold a metal part to be worked on. It is used for high-precision welding work.

3. Earth Clamp for Soil

This is an Earth Clamps that can be embedded in the ground. It is shaped like a pile. It is used in ground improvement work and geological surveys.

4. Magnetic Earth Clamp

This is an Earth Clamp that sticks to metal parts by means of magnets. It is characterized by the fact that it can be easily attached using magnetic force. They are used in electrical work and welding operations.

Aluminum cutting is a

Aluminum cutting is a

Asphalt Emulsions are materials that can be applied at room temperature. It can be applied at room temperature, whereas

Asphalt Emulsions are materials that can be applied at room temperature. It can be applied at room temperature, whereas