What Is a Threading Service?

A threading service is a process used to create screw threads. This service can apply to both male screws (common rod-shaped screws) and female screws (internal threads). The interaction between bolts and nuts exemplifies the relationship between male and female screws.

A threading service is a process used to create screw threads. This service can apply to both male screws (common rod-shaped screws) and female screws (internal threads). The interaction between bolts and nuts exemplifies the relationship between male and female screws.

1. Threading Service

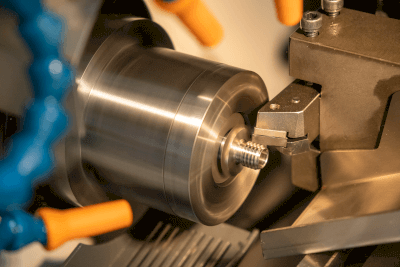

Threading can be performed using cutting techniques with a lathe or through plastic rolling methods.

2. Female Threading Service

Female threading involves similar techniques to male threading: cutting and plastic forming.

Uses of Threading Services

Threading services cater to various shapes, such as triangular, square, or trapezoidal threads, with triangular screws commonly used in machine parts. These services ensure threads conform to specific standards, like metric coarse threads, where the distance between adjacent threads is known as the pitch.

For smaller quantities, tools like dies and taps are used, while large-scale production employs processes such as cutting and threading using lathes and threading machines.

Types of Threading Services

Threads can be manufactured either by plastic forming or cutting service.

1. Plastic Forming

Plastic forming, which doesn’t produce cutting chips, includes methods like thread rolling. Thread rolling can be performed using flat dies, round dies, or segment dies. However, the process requires time for mold design and setup.

Threading services may also be executed using forging dies.

2. Cutting Process

Cutting services are versatile on a single lathe but are not ideal for mass production. External thread turning is used for male threads, while internal thread turning creates female threads. NC lathes, which automate all cutting operations, have become increasingly popular.

Threading machines, specialized for threading services, are used for items like anchor bolts in construction. The drawbacks of cutting include the generation of a large amount of waste, high costs due to cutting tools, and the time needed for tool changes.