What Is Brass Machining?

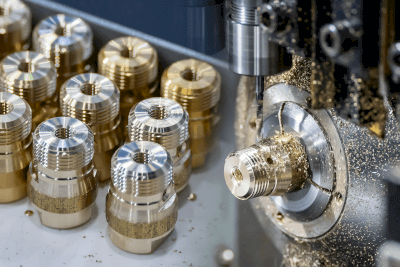

Brass machining involves using brass materials in various processing methods to create diverse products. The main types include cutting, casting, bending, and welding.

Known for its high ductility, brass does not easily break when stretched, making it suitable for stretching into plates or bending into thin wires. Its excellent hot castability also facilitates easier processing when heated, and its cutting workability makes it a preferred material in parts for watches and precision instruments.

Uses of Brass Machining

Brass is commonly used to manufacture machine parts, bolts, and nuts, which require precise cutting and bending, thanks to its outstanding machining properties. Beyond its functional advantages, the aesthetic appeal of brass makes it a popular choice in various non-industrial products as well.

Brass is also used in accessories, electrical outlets, and wiring, leveraging its high electrical conductivity. Its application extends to brass instruments, water pipes, architectural parts, and furniture fittings, among others.

Principles of Brass Machining

There are five key methods in brass machining:

1. Cutting

With its high machinability, brass is ideal for precision cutting using milling machines or lathes. This method is essential for producing clocks, machine parts, screws, and valves requiring precision machining.

2. Casting

Brass’s high hot forgeability allows for effective cast machining. Cast brass offers manufacturing flexibility but can be prone to air bubble formation, which may affect strength.

3. Cutting Process

Brass can be machined using laser, shearing, press, or chip saw. Laser cutting is particularly popular due to its processing speed and versatility.

4. Bending

Brass bending is achieved through press working or press braking, producing stronger bends compared to those made by cutting.

5. Welding Process

Welding brass is challenging due to its high thermal conductivity. Silver soldering, which melts at lower temperatures than brass, is often employed.

Despite its advantages, brass is susceptible to moisture and oxidation, often leading to a surface covered with oxidized copper. To prevent this, plating or clear coat treatments are applied. Additionally, brass is prone to deformation, warping, and burr formation during cutting, requiring careful post-processing maintenance.