What Is a Variable Resistor?

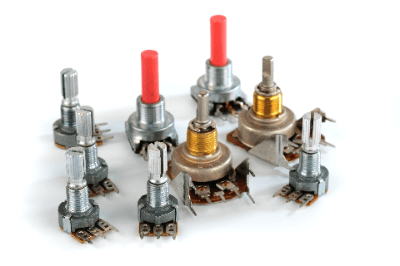

A variable resistor is a resistor whose resistance value can be freely changed.

Generally, it consists of a resistive element and a sliding element that moves on the surface of the resistive element. In other words, the resistance value is determined by the position of the sliding element.

Variable resistors are also sometimes called potentiometers.

Uses of Variable Resistors

Variable resistors are used in a variety of electronic devices. A typical example is the volume control mechanism in audio equipment. It is called a volume control.

Variable resistors are also used in game controllers, brightness adjustment mechanisms for lighting equipment, and position detection. For example, if a variable resistor is designed to move in synchronization with the windshield wipers of a car, the resistance value will change depending on the position of the windshield wipers. Using this feature, the position of the wipers can be detected by monitoring the resistance value of the variable resistor when controlling the movement of the wipers.

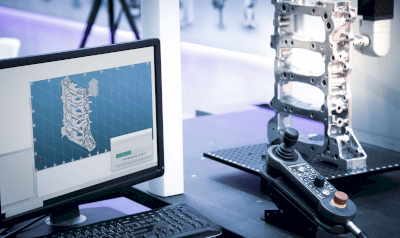

Because of these various applications, variable resistors are widely used not only in electronic equipment but also in marine equipment, medical equipment, construction machinery, and machine tools. Variable resistors include those whose resistance value is changed by turning a rotary shaft and those whose resistance value is changed by sliding a knob.

Principle of Variable Resistors

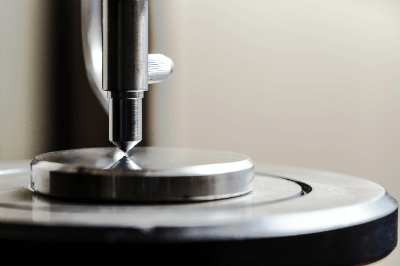

A variable resistor has both ends of a resistive element with a constant resistance value and three electrodes connected to a sliding element that moves on the resistive element. The resistance value between the electrodes on one side of the resistive element and the electrodes of the sliding element varies as the sliding element moves. When a voltage is applied between both terminals of the variable resistor’s resistive element, the voltage divided by the voltage is obtained from the terminals of the sliding element.

That is, when a signal voltage is applied to both ends of the resistive element, the signal voltage between one of the reference terminals and the sliding element terminal is determined by the position of the sliding element. Therefore, the level of the signal voltage can be controlled freely by moving the slider.

By applying a constant voltage to both ends of the resistive element and measuring the voltage between the reference terminal on one side and the sliding element terminal, a voltage corresponding to the position of the sliding element can be obtained. From this voltage, the position of the sliding element sliding element can be obtained, so it can be used as a displacement sensor.

Types of Variable Resistors

1. Classification by Rotary Shaft Movement

Linear Type

The linear type is a type with a sliding knob. In mutation sensor applications, it is used to detect a position on a straight line.

Rotation Type

The rotary type rotates a rotary shaft. In mutation sensor applications, it is used to detect the angle of rotation.

Multi Revolution Type

In order to change the resistance value with high accuracy, there is also a variable resistor called a multi-turn type. This type uses gears to decelerate the movement of the rotating shaft to enable subtle resistance value settings.

2. Classification by Resistance Value Change Characteristics

The resistance value of a variable resistor indicates the resistance value between the terminals at both ends of the resistive element, and generally, resistors in the range of 100Ω to 1MΩ are often used. In the rotary type variable resistors, there are three types of resistance value change with the rotation angle of the sliding element: Type B, which is a straight line; Type A, which is a logarithmic curve; and Type C, which is an inverse logarithmic curve.

Variable Resistors With A Curve Characteristics

Variable resistors are mainly used for volume control of audio equipment. Since human hearing is not proportional to the loudness of electrical signals, but to their logarithm. The A-curve characteristic is perceived as a linear change in volume by the auditory sense.

Variable Resistors With B Curve Characteristics

Variable resistors with B curve characteristics are used for adjusting electronic circuits, mutation sensors, etc.

Variable Resistors With C Curve Characteristics

This curve has the opposite characteristics of the A curve and is limited to special applications. Examples of use include adjustment of audio sound quality and effectors.

Other Information on Variable Resistors

Digital Variable Resistors

Digital variable resistors are electronic components whose resistance value can be varied by a controller, such as a PC, etc. A set of resistors and switch elements configured inside an IC can be switched by a control signal from the controller to set a desired resistance value.

Since there are no sliding elements, there is no abrasion, and a highly accurate resistance value can be obtained stably. There is also no noise generated by the sliding element. In addition, they generally have a long service life and high performance.