What Is a Laser Mirror?

Laser mirrors are specialized mirrors designed to reflect laser light.

They are characterized by high reflectivity and thermal tolerance and are used to maximize the energy of the laser beam. They serve various purposes in laser devices and optics, with their primary application being the focusing and propagation of laser light in the form of a beam.

The laser beam emitted from a laser device is directed by a laser mirror, allowing precise control of the beam’s direction. Laser mirrors are also used as reflectors for lasers. Ordinary mirrors can lead to thermal damage since laser beams are produced at specific wavelengths and power levels.

Laser mirrors are often manufactured with specialized coatings and materials that provide high reflectivity for specific wavelengths and power levels while minimizing thermal damage.

Uses of Laser Mirrors

Laser mirrors find applications in various fields and industries. Below are some examples of their uses:

1. Manufacturing

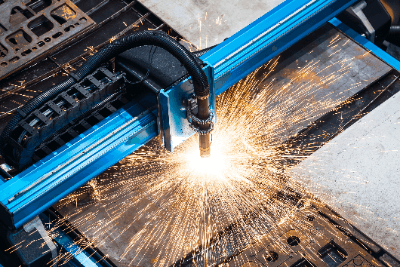

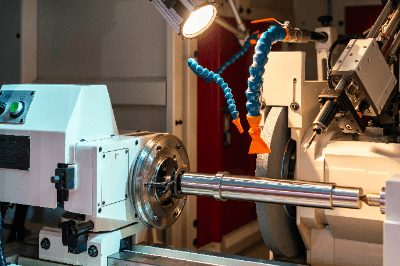

Laser mirrors play a vital role in manufacturing processes like laser cutting and laser marking. Their high reflectivity and heat tolerance enable precise laser beam guidance.

In laser cutting, laser mirrors focus the laser beam on the material to be cut. In laser marking equipment, a focused laser beam is used for marking or engraving. In laser welding, laser mirrors control the welding process by focusing the laser beam on the material.

2. Medical Applications

Laser mirrors are widely used in the medical field, particularly in laser surgery. They guide the laser beam into a patient’s body.

In skin treatments, mirrors are used to precisely direct the laser beam for treating skin lesions and unwanted tissue. In ophthalmic surgery, mirrors guide the laser beam into the eye for surgery or treatment. Laser mirrors are crucial for the effective and safe use of laser light due to their high reflectivity and heat tolerance.

3. Telecommunications

Laser mirrors are essential components in the field of fiber optics and optical communications. Optical fibers are used for high-speed transmission of information, and laser mirrors reflect and guide optical signals.

Mirrors are used at the ends and junctions of optical fibers to precisely control optical signals, ensuring high-speed, high-quality communication. Optical communication networks also employ mirrors for routing and optical switching to transmit and control signals effectively.

Principle of Laser Mirrors

A laser mirror consists of a reflective layer, a substrate, and a protective coating.

1. Reflective Layer

The reflective layer’s role is to reflect the laser beam and is typically coated with a highly reflective material like metal or dielectric deposition. The thickness and material choice depend on the mirror’s characteristics and the laser mirror’s wavelength.

2. Substrate

The substrate provides support to the reflective layer, ensuring stability. Typically, rigid materials like glass or metal are used. Substrate flatness and heat resistance are crucial, and high-quality substrates are preferred to maintain laser beam quality.

3. Protective Coating

A protective coating is often applied since laser mirrors may be exposed to dirt and scratches during use. This coating protects the mirror surface and enhances wear and chemical resistance.

Types of Laser Mirrors

There are several types of laser mirrors with varying coatings, properties, and applications. Here are some typical examples:

1. Metal Coating

These mirrors are coated with materials like gold, silver, or aluminum. They are cost-effective and suitable for a broad wavelength range.

Gold transmits at wavelengths of 600 nm or less, while silver transmits at wavelengths of 400 nm or less. However, they are susceptible to surface scratches.

2. Broadband Dielectric Coating

This type of mirror features a broadband, highly reflective coating. The film doesn’t absorb light and is used for laser light sources with multiple wavelengths.

3. Dielectric Coating for Lasers

These mirrors have coatings highly reflective at specific wavelengths. They are commonly used for short-wavelength lasers and high-power lasers. Additionally, they have the advantage of not absorbing light and are hard and scratch-resistant.