What Is a Plastic Rod?

A plastic rod is a rod-shaped product made from resin, a polymer compound. These rods are produced using various types of resins, each with unique properties and applications. Resin’s polymer structure, comprising long molecular chains, gives it distinct physical properties based on its composition.

Plastic rods are created by processing these resins and molding them into specific shapes and sizes.

Applications of Plastic Rods

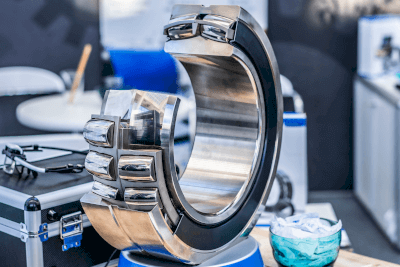

1. Industrial Product Parts

Utilized for their durability and lightweight, plastic rods are key components in machinery and equipment. They are found in bearings, gears, springs, shafts, and various machine elements.

2. Automotive Industry

Plastic rods contribute to the strength and lightweight nature of automotive interior and exterior components. Used in bumpers, door handles, and dashboards, they aid in fuel efficiency and reducing vehicle weight.

3. Electronics

With excellent electrical insulation properties, plastic rods are integral in electronic devices and electrical components. They are essential in printed circuit boards, terminals, and housings, enhancing safety and reliability.

4. Construction Materials

In construction, plastic rods are used for both exterior and interior materials. They enhance window frames, door handles, and lighting fixture components with weather resistance and durability.

5. Medical Equipment

Valued for their chemical resistance and biocompatibility, plastic rods are used in medical devices, instruments, and prostheses, ensuring patient safety and comfort.

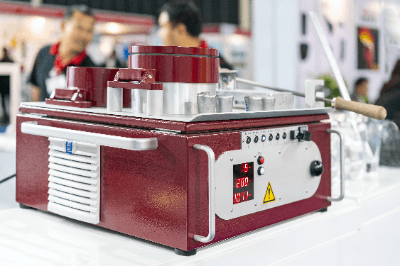

6. Industrial Equipment

Plastic rods serve as structural elements in industrial machinery, particularly in chemical and corrosive environments, where durability is crucial.

7. Crafts and Hobby

These rods find applications in crafts and hobbies, such as model making, jewelry, and art production.

8. Agricultural Tools

In agriculture, plastic rods reinforce nets, poles, and sprayer parts, offering durability and weather resistance.

Features of Plastic Rods

1. Light Weight and Strength

Plastic rods combine light weight with high strength, ideal for structural parts and reinforcement materials.

2. Durability

Resin’s weather resistance extends the product life of plastic rods, withstanding external and environmental changes.

3. Chemical Resistance

Some resins resist chemicals and corrosives, making them suitable for the chemical industry and research.

4. Electrical Insulation Properties

Their non-conductive nature makes plastic rods perfect as insulators in electronic and electrical components.

5. Processability

Resin’s moldability and ease of shaping allow for the creation of complex designs, broadening plastic rods’ applications.

6. Biocompatibility

Certain resins are biocompatible, ideal for medical devices requiring contact with human tissue.

7. Heat Insulation Properties

As heat insulators, plastic rods are used in construction and industry to protect against extreme temperatures.

8. Recyclability

The recyclability of some resins aligns with the growing emphasis on sustainable materials in today’s environmentally conscious world.

Types of Plastic Rods

1. Polyethylene (PE) Rods

PE rods, made of Polyethylene, offer durability, chemical resistance, and lightweight. They’re frequently used in water and chemical contact environments.

2. Polypropylene (PP) Rods

PP rods, made from polypropylene, exhibit heat resistance and electrical insulation, useful in the food industry and electronic equipment.

3. Polyurethane (PU) Rods

PU rods, made from polyurethane, are noted for their elasticity and abrasion resistance, vital in machine and vehicle part production.

4. Polyvinyl Chloride (PVC) Rods

PVC rods, made from PVC resin, are known for their weather and chemical resistance, widely used in building materials and water treatment components.

5. Acrylic (PMMA) Rods

PMMA rods, made from polymethyl methacrylate (acrylic), are used for their excellent light transmission properties in signboards, decorative items, and lighting components.

6. Delrin (POM) Rods

POM rods, made from polyacetal, are characterized by their wear resistance and low friction, suitable for gears, bearings, and machine parts.

7. Nylon (PA) Rods

PA rods, made from polyamide, excel in wear and chemical resistance, ideal for high-friction applications like gears and bearings.

8. Fluoroplastic (PTFE) Rods

PTFE rods, made from fluoroplastic, offer high heat resistance and chemical stability, essential in corrosive environments and high-temperature conditions.