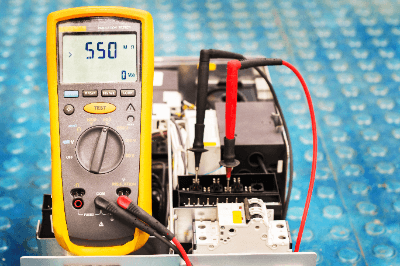

What Is an Insulation Tester?

An insulation tester is a device used to diagnose insulation conditions. Insulation resistance testers capable of applying high voltages of about 1,000 VDC according to the system voltage are also available.

It is essential for any equipment that uses electricity to be well insulated. If the insulation deteriorates, it can cause electrical leakage, fire, or electric shock. To prevent the above accidents from occurring, it is necessary to evaluate the insulation performance periodically with an insulation resistance tester.

Usage of Insulation Testers

Insulation testers are used to quantify insulation capability. It is rarely seen in ordinary households.

In production, they are used for the final testing of electrical products at the factory where they are shipped. In addition, maintenance personnel of electrical equipment often have it as a measuring instrument for maintenance.

Resistance measurement involves the application of a voltage, and the applied voltage varies according to the system voltage.

Insulation Tester Principle

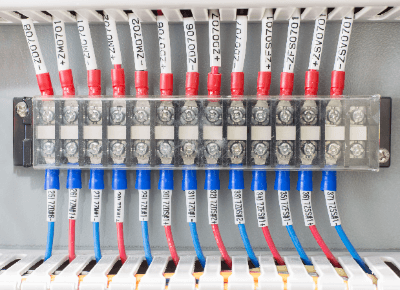

Insulation testers include wiring terminals, switches, DC power supplies, ammeters, and current protection elements.

The wiring terminal uses two terminals: the ground terminal and the line terminal. The ground terminal is grounded, and the line terminal is connected to the measuring section for measurement.

By pressing the switch, a DC voltage created by a DC power supply is applied. The minute current flowing to the earth is called leakage current, and the insulation resistance is obtained by measuring the leakage current when the voltage is used with an ammeter.

Since a high-voltage is applied, the impedance is increased with a current protection element to prevent overcurrents from flowing in the circuit. Due to the existing protection element, the internal impedance of the insulation resistance tester is designed to be very high.

The insulation performance is better with a higher the insulation resistance value. The insulation resistance value will be extremely low if an insulation breakdown occurs.

Other Information on Insulation Testers

Insulation resistance testers measure the insulation condition of electric lines and electrical components installed in factories and homes.

Causes of insulation defects may include poor installation of electrical circuits, poor insulation between charging and non-charging parts, deterioration over time, deterioration of internal wiring, damage due to shorts in parts used, and damage to the housing. If left unattended, these problems can lead to extremely dangerous electrical leakage, fires, and electrocution.

To prevent such problems, shut off the power supply system and measure insulation resistance as soon as the leakage breaker trips or an electric shock occur during operation appears.

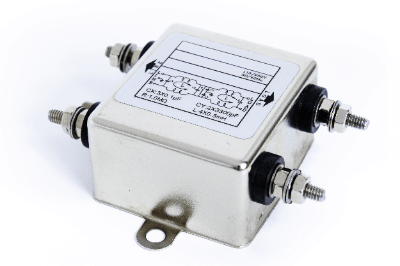

A noise filter is an electronic component used to remove noise from a power supply or signal.

A noise filter is an electronic component used to remove noise from a power supply or signal.