What Is a Resin Tube?

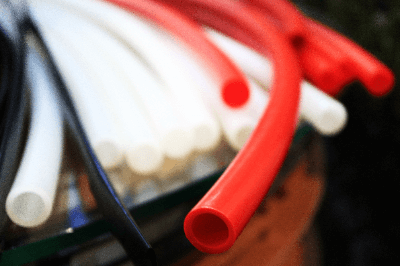

Resin tubes are tubes made from plastic.

Materials include polyolefin, polyurethane, and fluoropolymers. The durability, chemical resistance, and hardness of the tubing vary depending on the material and thickness. Therefore, the appropriate tubing should be selected according to the application.

Resin tubes are used to transport chemicals at various manufacturing sites for pharmaceuticals, chemicals, and inorganic materials. They are also useful as conductor sheathing due to their excellent electrical insulation properties. Resin tubes are also useful for coating conductors. While Resin tubes are conductive, some products have been developed to be electrically conductive, although normal tubes are easily electrically charged.

Applications of Resin Tubes

1. Medical Industry

Resin tubes play a vital role in the medical industry. They are used for intravenous catheters, conduits, drain tubes, and tubes for blood tests. The flexibility and smooth inner surface of resin tubes ensure patient comfort and safety during medical procedures.

2. Automotive Industry

In the automotive industry, resin tubes are widely employed in engine components, brake systems, and fuel delivery systems. Resin tubes are increasingly being used as alternatives to metal tubing in automotive parts where durability and chemical resistance are required.

3. Food Industry

Resin tubes are used for piping and transportation in the food industry. The tubing is suitable for transferring food and beverage fluids, exhibits high chemical resistance, and meets food safety standards. Resin tubes are commonly used in production lines for dairy products, beverages, and seasonings.

4. Electronics Industry

In the electronics industry, resin tubes serve as insulating material for electrical wires and coating circuit boards. The properties of resin tubes are crucial because they require high electrical insulation and heat resistance.

5. Agriculture and Horticulture Industry

Resin tubes also find applications in the agricultural and horticultural industries. They are used as sprinkler tubes for watering and fertilizer application and are sometimes integrated into agricultural machinery parts. Being lightweight and durable, they enhance the efficiency of agricultural operations.

6. General Industrial Use

Resin tubes are also extensively employed in various industrial applications. They are used in piping for a range of industrial machinery, including hydraulic and pneumatic equipment, gas supply systems, etc. Notably, their light weight and ease of handling facilitate installation and replacement work.

Features of Resin Tubes

1. Flexibility and Bendability

Resin tubes are crafted from flexible resin material. Thanks to this flexibility, they adapt easily to bending, twisting, and other deformations, making them suitable for installation in tight spaces and complex geometries.

2. Durability and Chemical Resistance

Resin tubes are made from durable resin material, providing them with exceptional durability for long-term use. Resin materials are also generally resistant to chemicals, playing a crucial role in industries handling chemicals due to their resistance to corrosion and deterioration.

3. Low Friction and Smooth Inner Surface

The smooth, low-friction inner surface of resin tubes enables smooth fluid movement, making them suitable for transporting liquids and gases with minimal energy loss.

4. Electrical Insulation Properties

Resin tubes typically exhibit high electrical insulation properties, making them widely used as insulating materials for electric wires and electrical equipment. They prevent the leakage of electrical signals, ensuring the safety of electrical systems.

5. Lightweight

Resin tubes are constructed from lightweight materials, making them easy to handle. Particularly in industrial fields where they are used in large quantities, their light weight contributes to cost reduction.

Types of Resin Tubes

1. PVC (Polyvinyl Chloride) Tubing

PVC tube is the most popular type of resin tube in general. Due to its flexibility and cost-effectiveness, it is widely used in various applications, including industrial and domestic applications such as water and air supply, drainage, and plumbing. Its excellent chemical resistance also makes it suitable for chemical transfer.

2. PU (Polyurethane) Tubing

PU tubing is characterized by excellent abrasion and oil resistance, high strength, and flexibility. These qualities make PU tubing widely used in industrial fields requiring high reliability, such as pneumatic tools, robots, and automotive braking systems.

3. Silicone Tubing

Silicone tubing offers excellent heat resistance and is suitable for high-temperature environments. It is commonly used in medical equipment and the food industry and is ideal for transporting chemicals and high-temperature liquids. Silicone tubing is highly durable and can withstand long-term use.

4. Fluorine Tubing

A Fluorine tube is a specialized resin tube with high chemical and heat resistance. It exhibits excellent resistance to strong acids, strong alkalis, and organic solvents, making it suitable for use in the semiconductor and chemical industries. It is also appropriate for transferring chemicals and solvents at high temperatures.

5. Nylon Tube

Nylon tubes offer excellent abrasion and oil resistance. They are used in fuel supply and brake systems in the automotive industry and pipelines for industrial machinery. The high tensile strength of these tubes makes them suitable for pneumatic tools and power transmission in robots.