What Is a Tip Dresser?

A tip dresser is a device used to reshape the electrodes of spot-welding machines to restore their weldability.

Previously, manual filing was commonly used for grinding electrodes, but this posed issues with worker safety, workload, and quality. Tip dressers address these concerns.

Tip dressers are particularly beneficial for achieving precise tip shapes, a task that is challenging with standard polishing machines.

Uses of Tip Dressers

Applied to spot welding equipment, tip dressers are used in various fields. They not only restore weldability but also remove burrs formed during welding.

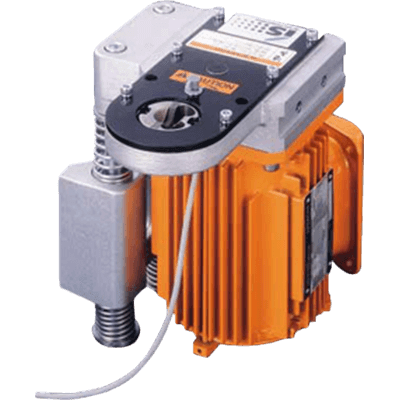

Available in both handy and stationary types, the handy type is ideal for on-site maintenance, while the stationary type is preferred for precision grinding.

Principles of Tip Dressers

The circular component, which contains the polishing parts, rotates at a high speed to efficiently grind the tip. Additionally, a floating unit is employed for vertical and precise polishing, reducing stress on both the tips and the dresser.

Some models feature a tip discrimination sensor for quick verification of proper polishing.

Advanced models use an electro-pneumatic proportional valve and a multi-function controller to apply appropriate pressure to the dresser electrode. General tip dressers can handle simple chip shapes like A, F, and P types, whereas special models are required for complex shapes like E and R types.