What Is a Power Roller?

A power roller is a roller equipped with an integrated drive motor and reduction gears.

Unlike standard conveyor systems that rely on separate drive components such as drive motors, drive chains, or sprockets, power rollers can rotate solely through the roller itself.

Power rollers are commonly used to drive belt conveyors and are also integrated into roller conveyors as part of the system.

Applications of Power Rollers

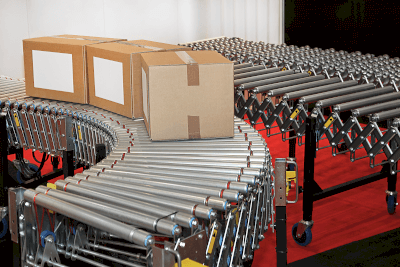

Power rollers serve as integral components in conveyor systems. They are installed at the ends of belt conveyors, functioning as drive pulleys, and they are also utilized in roller conveyors, which consist of multiple rollers arranged at regular intervals.

When integrated into a roller conveyor, the drive torque generated by the power roller is transmitted to the adjacent free rollers using a drive element like a V-belt, causing the other rollers to rotate.

Because they have built-in motors, power rollers can be combined with sensors and other control devices. When a load is introduced onto the conveyor, sensors detect it, allowing for precise control over conveyor movement and stopping.

Principles of Power Rollers

Each power roller incorporates a drive motor and reduction gear within the roller structure. Various types of power rollers are available to suit specific applications, including waterproof variants, models with integrated brakes, and those designed for curve conveyors.

A power line extends from the roller shaft, enabling power to be supplied to the internal motor by applying voltage to this power line. Power can be provided through both DC power supply and AC power supply. It is possible to directly supply AC power from the breaker, or the system can operate using DC power from a power supply source.

In the case of a power roller serving as a drive pulley for a belt conveyor, the belt and rollers are engaged by maintaining a certain tension in the belt, causing it to adhere to the rollers. This allows the drive torque to be transferred to the belt. To achieve this, a V-belt is employed, so power rollers equipped with V-pulleys are used. These power rollers feature a pulley groove on one side where the V-belt is secured, facilitating the transmission of driving torque to the free rollers.