What Is a Drill Press?

A drill press is a machine tool used to drill holes in materials such as wood, resin, and metal.

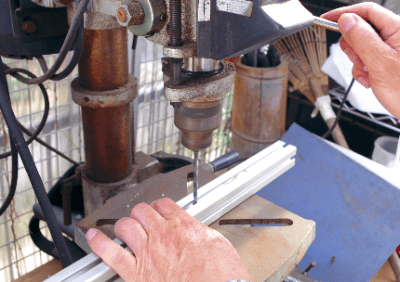

The material is fixed to the table, and a cutting tool such as a drill or reamer attached to the main spindle is rotated and the spindle is lowered toward the material for drilling. Drill presses are capable of drilling, expanding, reaming, tapping, buckling, and boring.

Uses of Drill Presses

Drill presses are often used to process and modify prototype parts before mass production.

Drill presses are not suitable for mass production, as milling machines and machining centers are superior in terms of automation. They are less expensive than other machine tools and are used for DIY and other personal manufacturing projects.

Drill Presses Principle

Drill presses can be used for a variety of machining operations by changing the tools to which they are attached.

1. Drilling

The basic use of a drill press is to drill a hole in a workpiece using a drill. This process includes ordinary solid drilling and trepanning, in which a large-diameter hole is drilled leaving a cylinder in the center of the hole.

2. Boring

A cutting tool called a boring bit is used to widen the inside diameter of the drilled hole to achieve dimensional accuracy.

3. Spot Boring

A large-diameter step is drilled into the top of the drilled hole using a boring drill, which is often used for hexagonal bolts.

4. Reaming

A tool called a reamer is used to improve the accuracy of the drilled hole. It is important to increase the rigidity of the spindle and chuck, since any vibration of the spindle or chuck will deteriorate the machining accuracy.

5. Threading

Threading is the process of creating the threads of a female thread using a tool called a tap in a drilled hole.

Types of Drill Presses

Drill presses come in a variety of types.

1. Upright Drill Presses

The most common drill presses are floor-mounted. The spindle head is moved manually or mechanically in the vertical direction to drill holes in workpieces placed directly under the spindle. The rotation speed of the main shaft can be changed by replacing the reduction gear. The hole diameter is about 13-50 mm.

2. Radial Drill Presses

Drill presses are larger than upright drill presses. The spindle head is mounted on a movable arm, and by moving the arm, several holes can be drilled without moving the large workpiece.

3. Tabletop Drill Presses

This is the smallest drill presses and is mainly used for DIY and simple processing. Drill presses are less accurate than upright drill presses, but they are easier to use. Hole diameter is up to about 13 mm.

4. Turret Ball Machine

A swivel table with several types of tools mounted on the main spindle allows multiple work processes by sequentially changing tools.

5. NC Drill Presses

High-precision machining is performed automatically by numerical control.

6. Other Drill Presses

Multi-axis drill presses are drilling presses with an increased number of spindles and can process multiple holes at the same time. Some drilling machines have 50 spindles and are used for machining special parts, etc., rather than general-purpose machines. A multi-head drilling machine is equipped with a large number of spindle heads, and can perform processing such as drilling, counterboring, and tapping in sequence with a single machine.

Other Information on Drill Presses

How to Use Drill Presses

1. Securely Install the Drill

If the drill is not securely fastened to the chuck, it will run dry during machining, resulting in loss of machining accuracy and damage to the Drill Presses.

2. Safety First

The use of gloves is extremely dangerous as they can get caught in the drill.

3. Fixation of Workpiece

The workpiece must be securely fastened using a clamp or vise.

4. Appropriate Rotation Speed

Appropriate rotation speed and feed rate should be selected according to the diameter of the drill and the hardness of the workpiece.