What Is a Power Conditioner?

A power conditioner is an inverter that converts the power generated by solar panels into commercial AC power. It also plays a key role in the system control of solar power generation.

A power conditioner is an inverter that converts the power generated by solar panels into commercial AC power. It also plays a key role in the system control of solar power generation.

Key functions include:

- Efficiency maximization in power generation

- Grid connection and disconnection control with the power utility

This latter function helps prevent issues like spillover accidents in case of system malfunctions. The efficiency of a power conditioner is indicated by its conversion efficiency, typically around 95%.

Uses of Power Conditioners

Power conditioners are essential in solar power generation systems, used in both industrial and private roof-mounted installations. They manage the connection and disconnection to the power grid and can serve as emergency power sources when paired with batteries, operating independently during disasters or power outages.

Principle of Power Conditioners

Power conditioners transform DC power from photovoltaic sources into AC power, compatible with electric utility transmission. Their components include:

- DC/DC Circuit: Stabilizes the power from the solar panels.

- DC/AC Circuit: Converts the stabilized DC power into AC power by rapidly switching polarity.

- Shutdown Circuit: Safeguards the system from spillover during abnormalities.

Post-conversion, the AC power is fed into the distribution board for use. Power conditioners also regulate current and voltage to optimize solar power utilization, adjusting to varying weather and sunlight conditions.

Other Information on Power Conditioners

1. Life Span of Power Conditioners

The lifespan of power conditioners, typically 10 to 15 years, is shorter than that of solar panels due to wear and deterioration of components like cooling fans. Regular maintenance, including filter cleaning and lubrication, can extend their service life.

2. Failure of Power Conditioners

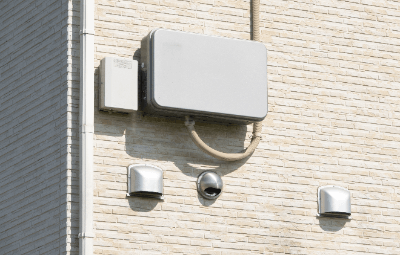

Failures can stem from poor installation connections, aging and heat, or external environmental factors. Examples include cable faults due to poor connections, component wear, or damage from rain, animals, and insects. Preventative measures include thorough installation management and sealing against environmental intrusions.