What Is Austenitic Stainless Steel?

Austenitic stainless steel is a general term for an alloy of stainless steel that has a crystal structure called austenite at room temperature.

It is classified as chromium-nickel stainless steel because it contains chromium and nickel in addition to iron as major components. The composition varies depending on the steel grade, but it is characterized by the presence of nickel as the main component to stabilize the austenite structure. It is the most commonly used material among stainless steel grades, and its production volume accounts for about 60% of all stainless steel.

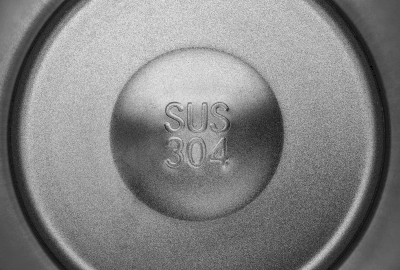

In particular, SUS 304, a typical austenitic Stainless Steel, is used in a very wide range of applications, and SUS 316, an alloy of SUS 304 to which molybdenum is added, is another alloy with high corrosion resistance.

Applications of Austenitic Stainless Steel

Austenitic stainless steel is used in a wide range of applications because it is generally non-magnetic and highly corrosion resistant, depending on the type of steel. Since austenitic stainless steels are not susceptible to loss of strength due to the external temperature environment and excel in welding and plastic working, they can be used in construction materials, plant equipment, and other applications where harsh conditions and reliability are required.

The most commonly used steel grade is SUS304. SUS305, which prevents work hardening, and SUS316, which offers improved corrosion resistance, are also widely used.

Properties of Austenitic Stainless Steel

Austenitic stainless steel has excellent toughness and ductility, making it suitable for cold working and press forming. They have good weldability, exhibit high hardness by heat treatment, and have the highest corrosion resistance of all stainless steels. It is not magnetic.

The reason for its lack of magnetism is that its crystal structure is a face-centered cubic lattice. If the structure transforms to martensite during plastic working, it may become magnetic in rare cases.

Austenitic stainless steel cannot be quenched to increase its strength, but its properties can be changed by solution treatment, annealing, and stabilization. Solution heat treatment is used for almost all austenitic stainless steel. Solution heat treatment improves corrosion resistance, reduces sensitization, and eliminates work hardening when heated to high temperatures and then quenched.

Structure of Austenitic Stainless Steel

The metallurgical structure of stainless steel is austenite at room temperature. In pure iron, austenite is formed only at high temperatures, while ferrite is formed at room temperature. When chromium is added to pure iron, the lowest temperature at which austenite is stable is approximately 830°C.

Ferrite-producing elements are those elements, such as chromium, that extend the temperature range of the stable existence of ferrite. The temperature range becomes smaller as chromium content increases above about 7%, and the stable existence temperature range of austenite eventually disappears as chromium content increases.

Elements that broaden the stable existence temperature region of austenite, such as nickel, are called austenite-producing elements. When nickel is added to pure iron, the austenite stable temperature range is broadened, with a minimum temperature of approximately 500°C at 30% nickel.

Types of Austenitic Stainless Steel

Austenitic stainless steel contains nickel and chromium and has higher corrosion resistance than other types of stainless steel. Localized corrosion such as pitting corrosion and intergranular corrosion may be a problem with SUS304, a typical austenitic stainless steel grade, but this can be addressed by changing the amount and type of additives. Specifically, SUS304L with a carbon content of 0.03% or less and SUS316 with molybdenum additives have higher corrosion resistance than SUS304.