What Is an Oil Skimmer?

A floating oil skimmer is a device to recover unwanted oil (floating oil) from water-soluble coolant used as cutting oil in machine tools such as lathes and milling machines. It is also called an oil skimmer.

Floating oil includes lubricating oil and hydraulic oil, which can cause coolant rancidity and foul odors.

The use of an oil skimmer will recover the oil that causes these problems, thereby extending the life of the cutting tool.

There are two types of oil recovery methods: the belt type and the screw type, with the belt type being more commonly used today.

Uses of Oil Skimmers

Oil skimmers are mainly used in coolant tanks of machine tools for cutting and in drainage tanks in factories.

Since hydraulic oil and lubricating oil tend to get mixed in with the coolant during the machining process, the oil must be removed frequently to keep the coolant clean.

Oil can also contaminate the water discharged from the factory. If these are released into the environment, they can be a serious cause of environmental pollution.

Oil skimmers can be used to clean wastewater and help prevent environmental pollution.

Principle of Oil Skimmers

Floating oil gradually accumulates in the coolant reservoirs used in machine tools.

This floating oil can cause coolant rancidity and foul odors, which can lead to deterioration of work environment safety as well as contribute to environmental pollution due to wastewater.

Floating oil skimmers must be used to remove the floating oil.

Oil skimmers are classified into belt-type and screw-type depending on the oil skimming method.

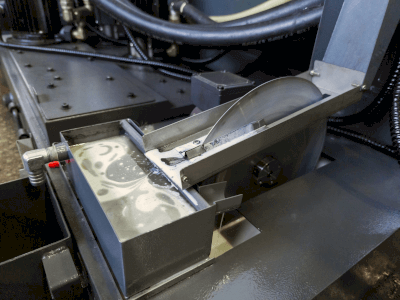

Belt-Type Oil Skimmers

In the belt-type, a rotating plastic or steel belt is installed in the storage tank, and the liquid adhering to the belt is discharged into a separate tank (separation tank).

The discharged liquid is separated into oil and water in the separation tank, and only the surface floating oil is discharged through the collection port, leaving coolant in the small tank.

Screw-Type Oil Skimmers

In the screw-type, a screw with a special helical structure is rotated to collect oil.

By utilizing the difference in viscosity between aqueous solution and oil, only oil with high viscosity adheres to the screw.

Unlike the belt-type, this system does not require a tank for separating coolant and oil.