What Is a Drive Chain?

A drive chain is a chain utilized to transmit power between rotating shafts that are spaced apart.

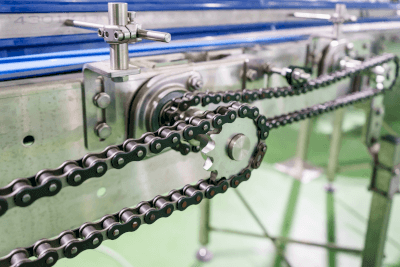

Most drive chains consist of metal roller chains. These roller chains operate in tandem with sprockets and thin gears to transfer power from the input to the output shaft.

Altering the sprocket teeth count on both the drive and driven ends can modify the rotation speed. Beyond drive chains, conveyor chains are also used in factories for product transportation along production lines.

Uses of Drive Chains

Drive chains find application in driving the wheels of bicycles and motorcycles, in automobile engines and transmissions, and industrial machinery. Bicycle drive chains represent a common example of their application in everyday life.

Drive chains in sports bicycles, like road and mountain bikes, must not only convey power but also adapt to various speed shifts. The chainring and the rear wheel sprockets, featuring different teeth counts, can be swapped to alter gear ratios.

The design of the drive chain allows significant lateral movement based on the sprocket’s position, enhancing its versatility. In automobiles, drive chains are integral to engine timing, transferring power in 4-wheel drives, linking transmissions to drive wheels in motorcycles, and operating in chainsaws and forklifts.

Principle of Drive Chains

The drive chain transmits power as the teeth of the driven sprocket engage the chain’s rollers, thus pulling the chain. Rollers, maintained in position by pins and bushings, with plates affixed on either side, facilitate continuous power transmission.

Structure of Drive Chains

The drive chain comprises four main components: pins, bushings, rollers, and plates.

1. Pin

Pins support rollers that directly receive power from sprockets and connect the plates. They must withstand significant shear stress during power transmission.

2. Bushing

Bushings facilitate the smooth sliding action between pins and rollers, essential when rollers engage with sprockets under pressure, thereby minimizing friction and wear.

3. Plate

Plates, connected by pins, transmit power under tension. Inner and outer plates are arranged alternately, and chains must be linked by connecting these plates.

4. Sealing Rings

Certain drive chains include sealing rings to encase lubricating grease for the bushings.

Other Information on Drive Chains

1. Standards for Drive Chain

Drive chains adhere to various domestic and international standards. Chain sizes are denoted in inches, with a three-digit number representing the pitch and inner pin width.

2. Alternatives to Drive Chain for Power Transmission

Aside from drive chains, rubber belts, gears, and shafts also transmit power. Nevertheless, drive chains are prevalent in daily-use products like cars and motorcycles due to their reliability and cost efficiency. Metal belts are commonly used in continuously variable transmissions (CVTs) for vehicles, though metal chains are sometimes preferred for their torque transmission efficiency despite being noisier, limiting their market presence.