What Is a Miter Gear?

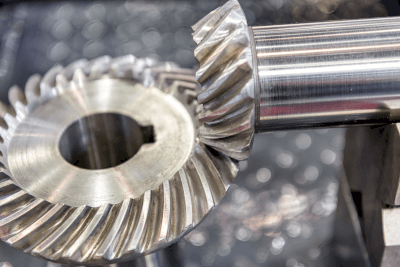

A miter gear, a specific bevel gear, is designed to transmit rotational motion to an orthogonal axis. This gear is typically shaped like the umbrella of a mushroom, and when two miter gears mesh at right angles to each other, they can effectively transfer motion.

While bevel gears come in various angles and tooth counts, miter gears are characterized by:

- Meshing gears having an equal number of teeth, preventing compatibility with gears of different tooth counts.

- Gears meshing at a 90-degree angle.

Consequently, miter gears are primarily used to alter the rotation direction by 90° while preserving the same rotational speed.

Uses of Miter Gears

Miter gears are crucial in transmitting rotation to a perpendicular shaft without altering the rotational speed. For instance, if shafts A and B intersect at right angles, miter gears attached to both shafts allow shaft B to rotate at the same speed as shaft A through seamless teeth meshing.

These gears are essential in applications like conveyor belts, machine tools, and automotive gears.

Principle of Miter Gears

As a subclass of bevel gears, miter gears are conical or mushroom-shaped, distinct in their 1:1 tooth ratio and a 90° crossing angle. This equal tooth count means miter gears are incompatible with gears having different numbers of teeth and must be mounted to intersect at 90 degrees.

Miter gears feature a keyhole-shaped hole for the rotating shaft, accommodating a keyed shaft. The shaft’s keyway aligns with the miter gear’s keyhole, and a metal fitting (key) secures the gear in place.

Typically made from S45C, a carbon steel for machine structural use, miter gears are hardened for enhanced tooth strength. Adequate bending strength prevents tooth breakage from the root, while sufficient tooth surface strength avoids chipping. It’s vital to adhere to specifications and ensure the mechanical device’s rotational energy stays within the gear’s load capacity.