What Is a Pipe Threader?

A pipe threader, often used at construction sites, processes external threads on pipes, facilitating the connection of water and gas pipes. This equipment is crucial for fitting pipes to required lengths and threading them to ensure secure connections, and varies from manual threading dies, suitable for smaller pipes, to powerful machines designed for large-diameter pipes which require significant force for threading.

Uses of Pipe Threaders

Pipe threaders are indispensable at construction sites for connecting pipes such as water, gas, and electric conduit pipes. Cutting threads directly into pipes and securing them with connectors ensures a robust connection, ideal for stable installations. Despite the hardness, corrosion resistance, and cost-effectiveness of stainless steel pipes, their challenging processing requirements make pipe threaders a necessary tool. Available in both manual and electric models, electric pipe threaders are preferred for their speed and convenience, with manual versions serving as backups in areas without power.

These machines are versatile, capable of threading bolts and conduit pipes in addition to gas and water pipes.

Principle of Pipe Threaders

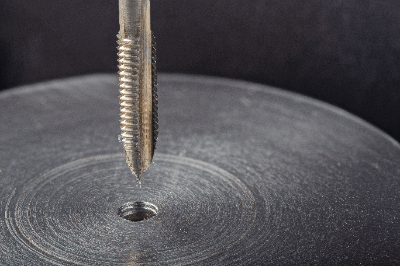

Pipe threaders operate by cutting threads with a die head and chasers. The die head secures the chasers, the blades that form the external thread on the pipe. It ensures the screws are cut to precise sizes, holding four chasers at a 90° angle. Different sized threads can be achieved by swapping out the die head. The chasers, directly contacting the pipe, have a thread shape matching the standard, with multiple blades arranged in concave and convex patterns. Threading is executed by positioning the pipe with the set die head and chasers and rotating it to form the threads.

Types of Pipe Threaders

Electric pipe threaders primarily come in two variants.

Automatic Cut-off Threaders

Automatic pipe threaders allow for setting the desired thread length, automatically stopping the threading process once the set length is achieved. This type is widely used for its efficiency and precision.

Manual Cut-up Threaders

Manual pipe threaders require the operator to manually monitor and control the thread length during processing, offering more control at the cost of increased labor.

Other Information on Pipe Threaders

Thread Roller

Thread rollers, which utilize pressure instead of cutting to form threads, deform the pipe surface plastically. This method preserves the pipe’s wall thickness, resulting in stronger pipe connections compared to the chaser type, albeit at a higher cost.

Precautions for Using Pipe Threaders

Using thread cutting oil is crucial when working with chasers to prevent damage and extend their lifespan. Additionally, the choice of chasers must correspond to the piping material to avoid unnecessary wear, underscoring the importance of a thorough pre-use check of the chasers.