What Is a Pumping Engine?

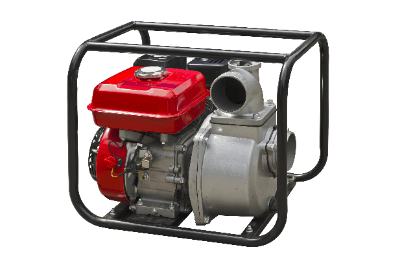

Pumping engines are driven by internal combustion engines and are designed to move fluids efficiently. These engines enable operation in remote or unstable power supply locations, making them invaluable for rural areas, construction sites, and emergency disaster response. With robust and reliable designs, they excel in challenging environments and can move large volumes of liquid quickly for tasks like drainage and firefighting.

Using the correct fuel and lubricants is crucial for safety and performance. Proper handling minimizes risks of leaks and fires, and it’s essential to implement fire safety measures due to the engine’s heat output.

Uses of Pumping Engines

Pumping engines serve various roles across multiple industries, including:

- Fire Fighting – They provide high-pressure water flow for firefighting, integral to extinguishing forest and vehicle fires.

- Agriculture – Used for irrigation, pesticide and fertilizer application, and drainage, they enhance crop growth and manage water levels in fields.

- Disaster Response – During floods, they play a critical role in water removal and levee reinforcement, and can supply drinking water or support sewage drainage for sanitation post-disaster.

Principle of Pumping Engines

Pumping engines combine an internal combustion engine with a pump to move liquids. These engines, which can be gasoline or diesel-powered, convert fuel energy into mechanical motion to drive the pump. The pump’s components, including the impeller, create suction and pressure to efficiently move liquids through the system.

Types of Pumping Engines

Pumping engines are categorized by their internal combustion engine type.

2-Cycle Engine Pump

These are lightweight, compact, and relatively simple to maintain, suitable for portable applications and light-duty tasks. They have a simple two-stroke operation cycle, but may have lower fuel efficiency.

4-Cycle Engine Pump

Four-stroke engine pumps offer high efficiency and lower emissions, making them ideal for industrial use and demanding applications. They feature a more complex design with distinct operational phases, requiring regular maintenance.