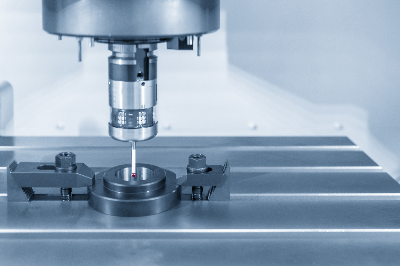

What Is a Ring Gauge?

A ring gauge is a measuring instrument used to measure the inside diameter of holes or to control the diameter of shafts and cylinders through threaded inspection. It is also used as a master gauge for calibrating other inside diameter measuring instruments.

Uses of Ring Gauges

Ring gauges are used for multiple purposes, including:

- Setting zero points for bore measuring instruments like cylinder gauges and micrometers.

- Dimensional inspection of shafts and cylindrical parts in manufacturing.

- Quick inspection of thread geometry with thread ring gauges.

Principle of Ring Gauges

Ring gauges operate on the principle of ensuring measurement accuracy and making pass/fail decisions for inspected products by maintaining precise dimensions. They must resist wear and dimensional changes over time. Common materials include tool steel and cemented carbide for their durability and resistance to wear. Finishing processes like grinding and lapping are applied to prolong the lifespan of the gauges.

Other Information on Ring Gauges

1. Precautions for Using Ring Gauges

Care must be taken when handling ring gauges as they are susceptible to dimensional changes due to thermal expansion. Both the gauges and the workpieces being measured should be at a stable temperature during inspection to ensure accurate readings.

2. Calibration of Ring Gauges

Regular calibration of both master and limit ring gauges is necessary to maintain accuracy. Calibration should be conducted by the manufacturer or a specialized measurement company. This is especially crucial for threaded gauges in thread ring gauges, which can wear out and change dimensions over time, affecting the inspection process.