What Is a Grease Cup

Grease cups are a type of lubricator used to supply oil (lubricant) to parts of machines and equipment that require lubrication.

These cups play a crucial role in ensuring smooth operation and reducing friction in various mechanical systems. Grease cups can be attached to machines and equipment to facilitate the easy and controlled supply of a fixed amount of oil. They are known for their simple structure, high reliability, and cost-effective maintenance benefits for machinery and equipment.

Uses of Grease Cups

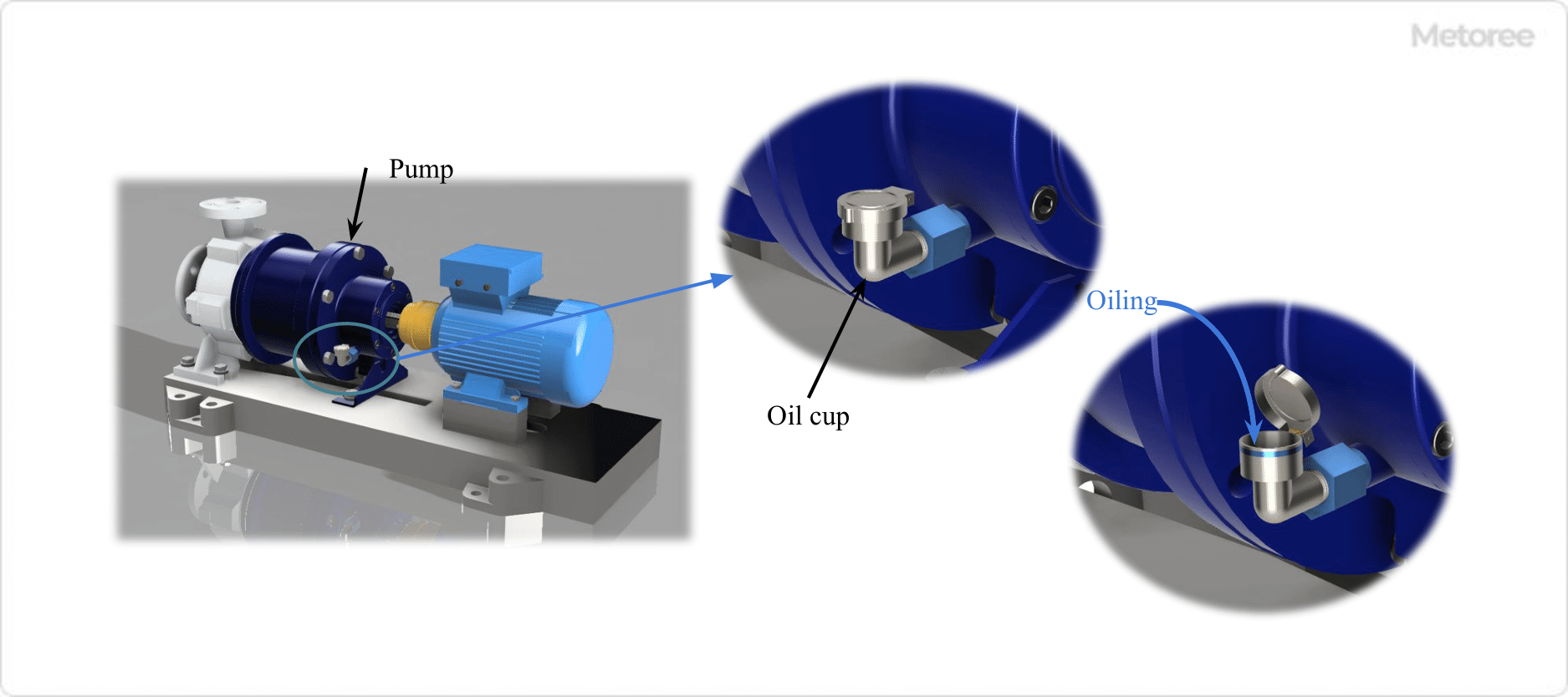

Figure 1. Example of oil cup use

Grease cups find applications in lubricating, cooling, and maintaining machinery and equipment. Here are some common uses of grease cups:

1. Lubrication and Cooling

Grease cups are used to supply the required amount of oil to frictional and operating parts of machines and equipment. They also provide oil to areas that generate heat, helping to absorb and dissipate heat, thereby preventing overheating.

2. Oil Supply to Gearboxes

Grease cups are used to supply oil to components and mechanisms such as gearboxes to ensure accurate gear operation and reduce friction. They are filled with the required amount of oil to maintain the proper oil level.

3. Bearing Lubrication

Grease cups are installed in the bearings of machines and equipment to provide the necessary amount of oil to reduce friction and wear in the bearings. By filling them with the required amount of oil, the proper oil level can be maintained.

Principle of Grease Cups

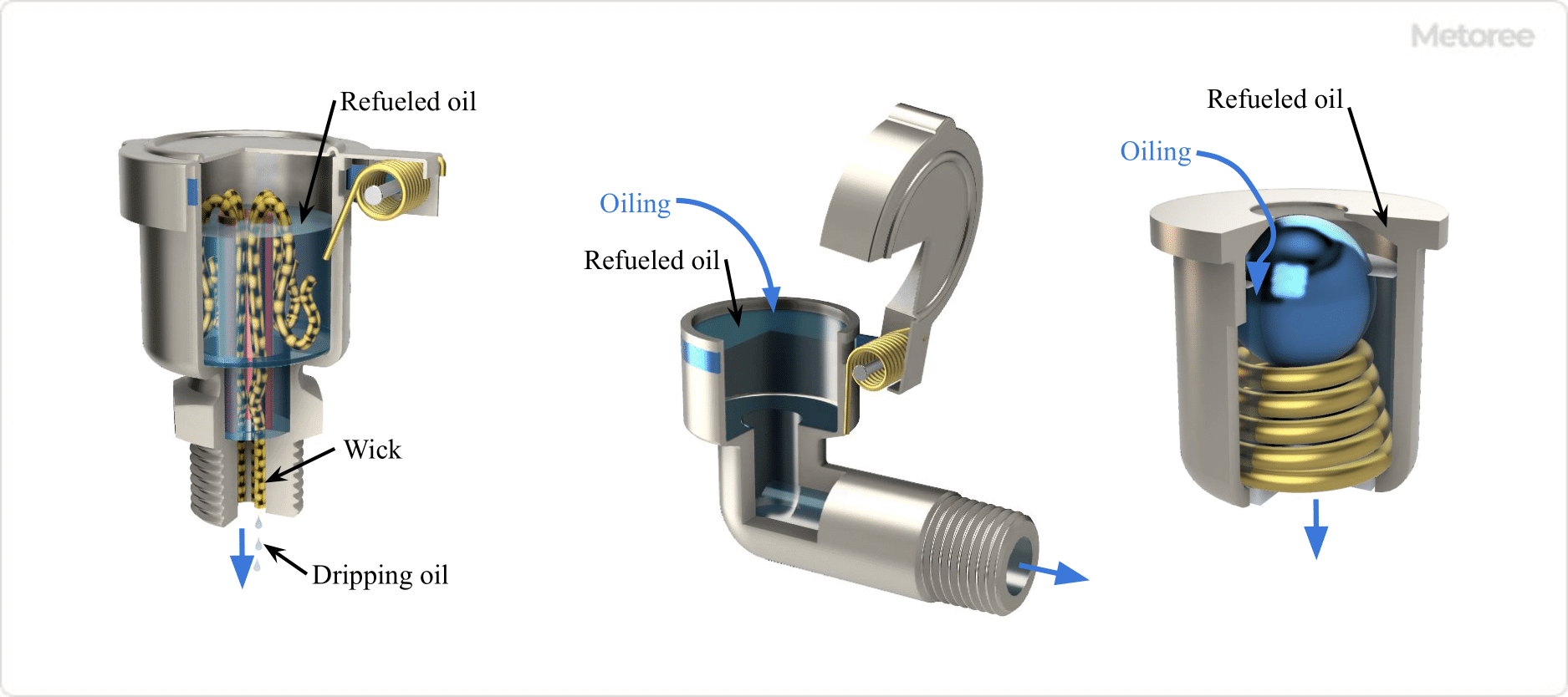

Figure 2. Principle of the oil cup

The principle and role of the grease cup are as follows:

1. Capillary Action

Grease cups are equipped with lamp cores that extend from the cup into the machine or equipment. These lamp cores draw in oil through capillary action, causing a small amount of oil to drip into the machine. This phenomenon helps control the rate of oil delivery and prevents excessive oil supply.

2. Oil Reservoir

oil cups also serve as reservoirs that hold a certain amount of oil. The oil level in the cup indicates the oil level in the machine or equipment, allowing for visual monitoring. As the machine operates and consumes oil, more oil is supplied from the cup to maintain the proper oil level.

Types of Grease Cups

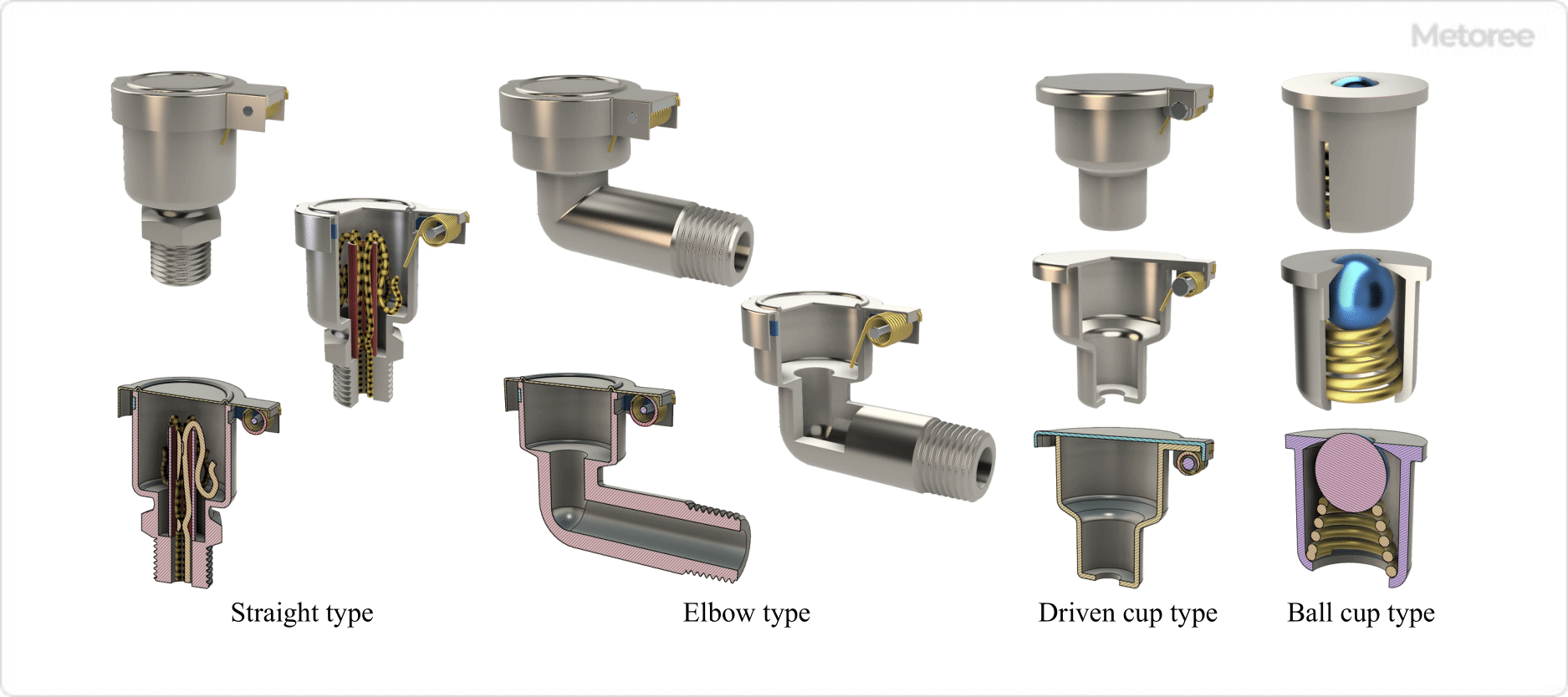

Figure 3. Types of oil cups

Grease cups come in various types based on their feeding method, shape, and structure:

1. Classification by Feeding Method

Grease cups use the capillary action method and lamp cores for oil delivery. The rate of oil supply can be adjusted by changing the thickness, number, and material of the lamp cores.

2. Classification by Shape and Structure

- Straight and Elbow: These cups can be straight or bent at a 90-degree angle. They are equipped with a cover that remains closed to prevent dust and particles from entering the cup.

- Threaded and Punch-in: Cups can be threaded or punched-in for mounting on machines and equipment. Threaded types are screwed into a female thread on the mating side, while punch-in types are embedded in a hole on the mating side.

- Ball-Loading: These cups contain a ball and spring mechanism. Oil is supplied by pushing the ball with a refueling pot or similar tool. The spring keeps the ball pressed against the cup lid to prevent dust ingress.

Other Information on Grease Cups

Installation Position of Grease Cup

When using grease cups for direct lubrication, it’s essential to consider the mounting position carefully. The cup should be installed so that the oil level in the cup matches the required oil level in the machine or equipment. For light-core types that drip oil, the cup should be mounted at a higher position, regardless of the required oil level in the machine or equipment.