What Is Vacuum Equipment?

Vacuum equipment is equipment that creates a vacuum using a certain power source.

There are three main types of vacuum equipment: ejectors, vacuum pumps, and vacuum blowers. Each is used for different purposes. The main applications of a vacuum include adsorption by suction pads and degassing by reducing the pressure in the system.

Among vacuum equipment, ejectors are very useful because they can be used in areas where hazardous materials are used by using air as the driving force. Vacuum pumps and blowers, on the other hand, are electrically driven and can efficiently create a vacuum.

Uses of Vacuum Equipment

One application of a vacuum is suction with suction pads. This is used to lift a workpiece by adsorbing it when it is transported by a robot or other equipment.

It is also used for degassing by reducing the pressure in a system. For easily oxidizable materials, it prevents oxidation by removing air (oxygen). They can also be used to separate or concentrate liquids by evaporating unwanted water from mixtures or chemicals.

Among vacuum equipment, ejectors use air and are used to generate vacuum inexpensively due to their small size and simplicity. Vacuum pumps are used to create a high vacuum, while vacuum blowers are used to vacuum vented workpieces.

Principle of Vacuum Equipment

Ejectors use the Venturi effect to create a vacuum. The inside of the ejector has a partially constricted structure that allows air, the driving fluid, to pass through at high speed. The area where the air passes through at high speed becomes partially vacuumed. Because of this principle, the driving source is a fluid, and there is a wide variety. Various fluids, such as steam, air, water, etc., can be used.

The vacuum pump rotates the vanes as the motor rotates, and the gas inside the casing is discharged while being sealed. Since the gas is continuously discharged and the motor can be used as the power source, high vacuum and pumping speeds can be achieved. They are also used as pressure reducing equipment to lower the boiling point.

Vacuum blowers use a motor to rotate the built-in blades. As the blower blades rotate, gas is drawn in. By drawing in gas, the gas is compressed to create a vacuum. The feature of the vacuum blower is its large suction volume. However, due to its principle, it can be used more efficiently if the workpiece to be adsorbed has air permeability.

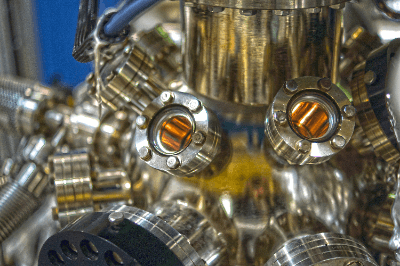

Structure of Vacuum Equipment

Vacuum equipment has different functions depending on the equipment, but the common unit consists of a vacuum pump (ejector, vacuum blower), vacuum chamber, vacuum valve, and vacuum gauge.

1. Vacuum Pump

A vacuum pump is a machine that releases the air in a vacuum chamber to the outside and maintains a low pressure, or vacuum, below atmospheric pressure. The type of vacuum pump used depends on the degree of vacuum required and the composition of the gas to be evacuated. The most common type of vacuum pump is the rotary pump, which is superior in terms of displacement volume, pressure limits, and cost.

2. Vacuum Chamber

A vacuum chamber is a container for creating a vacuum. The vacuum chamber uses a vacuum pump to expel air, which causes the pressure inside the container to drop. When the pressure drops, the vacuum chamber is subjected to pressure from the outside because the outside air pressure is greater than the air pressure inside the vacuum chamber. Therefore, if the vacuum chamber itself cannot withstand the pressure generated, it will not be able to maintain its shape, so care must be taken in selecting the strength of the vacuum chamber.

3. Vacuum Valve

A vacuum valve is a unit that shuts off the different pressures between the vacuum chamber and the vacuum pump. There are different types of vacuum valves, such as the gate bubble, the L-shaped valve, and straight bubble, and the vacuum valve to be used must be selected according to the pressure.

4. Vacuum Gauge

A vacuum gauge is a device that measures the pressure inside a vacuum chamber. Different types of vacuum gauges can measure different amounts of pressure, so it is necessary to use a vacuum gauge that is appropriate for the pressure of the vacuum equipment to be used.