What Is a Motor Pump?

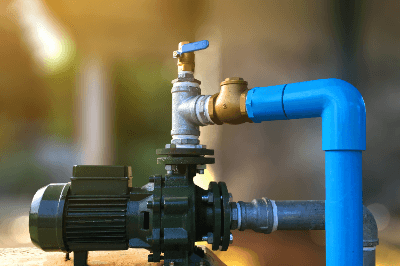

A motor pump is a device that combines a pump with a motor as its driving force. This integrated structure is commonly referred to as a motor pump.

The motor provides power to the pump, which is responsible for moving liquids or gases. Connected to a power source, the motor’s rotation activates the pump. Motor pumps are capable of generating high pressures and flow rates, making them suitable for long-distance fluid transportation and high-pressure applications such as water supply systems and fire pumps.

While motor pumps are prevalent, other types like air-driven pumps and engine pumps are also used.

Applications of Motor Pumps

Motor pumps have a vast array of applications:

1. Tap Water Supply

Commonly used in high-rise buildings to supply tap water to upper floors, motor pumps are effective in pumping water at high pressures. They are also used in irrigation systems for farmlands and greenhouses, drawing water from various sources like wells and rivers.

2. Drainage

Motor pumps are essential for draining spring water in basements and underground parking lots, efficiently moving wastewater to sewage systems. They are also utilized for domestic wastewater disposal in bathrooms and toilets.

3. Industry

In industrial settings, motor pumps are used for liquid fuel delivery and equipment cooling in boiler systems, particularly in power plants and manufacturing facilities. They also circulate lubricating oil in steam turbines to reduce wear from friction and heat.

Principle of Motor Pump

A motor pump comprises a motor and a pump section.

The motor, typically an induction motor known for its durability and ease of maintenance, rotates its shaft using a magnetic field and induced current. The motor shaft is connected to the pump shaft through a coupling, which in turn rotates the impeller of the pump. Centrifugal force pumps the fluid, and a mechanical seal and gland packing at the impeller base prevent leaks, though they require periodic replacement.

Types of Motor Pumps

Motor pumps vary depending on their pumping mechanisms:

1. Volute Pump

This centrifugal pump features an impeller within a volute-shaped casing. Fluid enters through the suction port, is propelled outward by the impeller, and is converted to pressure in the volute chamber.

2. Diaphragm Pump

Diaphragm pumps operate by reciprocating a membrane or diaphragm. With strong self-priming capabilities, they are suitable for high-head and high-viscosity liquids, often used in chemical plants.

3. Propeller Pump

Propeller pumps use a rotating propeller within a cylindrical housing to move fluid. These pumps are efficient at moving large volumes of liquid at low pressures but are not ideal for high-pressure applications.