What Is a Steam Flowmeter?

A steam flowmeter is an essential measurement device used for determining the flow rate of steam. Steam, which is a gaseous form of water with thermal energy, plays a crucial role in various industrial processes and energy management. Accurately measuring its flow rate is of paramount importance in these applications.

Steam flowmeters are employed to precisely control steam supply, enhancing process stability and efficiency. Maintaining appropriate steam flow rates can boost productivity and conserve energy resources.

Moreover, these instruments facilitate steam system maintenance and fault detection. By monitoring steam flow with precision, they enable early detection of steam leaks and other issues, contributing to improved system reliability and extended equipment lifespan.

Applications of Steam Flowmeter

Steam flowmeters are instrumental devices used across diverse industrial sectors. Here are some key applications:

1. Power Plants

In power plants, steam flowmeters are used in steam turbine power generation to measure steam flow from boilers. This allows for accurate electricity generation metering and efficiency optimization. Additionally, these flowmeters find use in gas turbines within cogeneration systems, where waste heat from gas turbines is converted into steam for dual energy production.

2. Iron and Metal Smelting Plants

Steel mills use steam flowmeters to control oxygen injection into blast furnaces, a vital process for converting iron ore into iron. These flowmeters are also common in metal refineries, where waste heat from exhaust gases is converted into steam, enhancing overall efficiency.

3. Food Processing Plants

Food processing facilities rely on steam flowmeters to regulate the supply of steam for heating equipment and jacketed tanks. Accurate control of steam ensures product quality and heating efficiency in this industry.

Principle of Steam Flowmeter

Steam flowmeters operate on a basic principle that involves measuring changes in physical parameters proportional to steam flow rate. The specific parameters measured may vary depending on the flowmeter’s type and sensor, including steam temperature, pressure, vibration, or heat dissipation.

Types of Steam Flowmeter

Various types of steam flowmeters are available, each with unique characteristics. Here are some common types:

1. Differential Pressure Type

The differential pressure steam flowmeter calculates steam flow by measuring the pressure difference caused by flow obstruction devices installed in the steam pipe. Devices like orifice plates and pitot tubes are commonly used. This type offers cost-effective solutions, even for large pipe diameters. Orifice plates, in particular, are compact, lightweight, and easy to install.

However, differential pressure steam flowmeters restrict steam flow, leading to pressure drops that should be considered during meter selection or design.

2. Ultrasonic Type

Ultrasonic steam flowmeters estimate flow rates by analyzing the phase changes of ultrasonic waves reflected off steam. They consist of a transmitter emitting ultrasonic waves and a receiver. These flowmeters offer contactless flow measurements with no pressure loss.

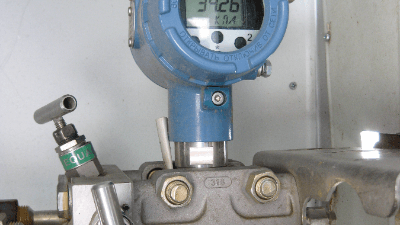

3. Vortex Type

Vortex steam flowmeters determine flow rates by monitoring the number and frequency of Karman vortices generated within the pipe. They consist of a vortex generator and a vortex detection sensor. These flowmeters have no moving parts, ensuring robustness and extremely high measurement accuracy.