What Is a Film Thickness Meter?

A film thickness meter is a device that measures the minute thickness of an object.

A film thickness meter is a device that measures the minute thickness of an object.

For example, it is used to examine thin films that are difficult to measure visually, such as the thickness of paint film or metal plating. There are several types of film thickness meters, and the measurement method is selected according to whether the object to be measured is light-transparent or not, and whether the measurement is done by contact or non-contact.

Uses of Film Thickness Meters

Film thickness meters are mainly used to measure the thickness of painted surfaces. Paint is applied to many everyday items such as home appliances, automobiles, etc., to maintain their durability as well as to maintain their aesthetics.

The thickness of the paint film must be appropriate and uniform. If the film thickness is not appropriate, i.e., if it is too thick, cracks may occur. If it is too thin, discoloration, loss of luster and deterioration of the substrate may occur. If the coating is not uniform, the durability may vary from place to place, making it impossible to maintain quality.

Therefore, a common method of quality control is to use film thickness meters to measure and control the thickness of the coated film on various items. There are various types of film thickness meters, and the appropriate device is used depending on the object to be measured. For example, when measuring the thickness of a transparent thin film, a spectral interferometer that uses a broadband light beam or an infrared film thickness meter that uses infrared light is used.

However, these methods cannot be used for metals because they do not allow light to pass through. When measuring metal plated thin films, electromagnetic film thickness meters that use changes in magnetic flux or eddy-current film thickness meters that use eddy-currents are suitable. In addition, non-contact film thickness meters, such as ultrasonic film thickness meters, are also used when it is difficult to make contact with the object to be measured.

Principle of Film Thickness Meters

Film thickness meters are available in a variety of measuring methods, and the appropriate device is used depending on the object to be measured. The following five methods are typical.

1. Spectral Interferometry Film Thickness Meter

This is a film thickness meter that uses light interference. When light is incident on the object to be measured, light is reflected from the surface and the back of the thin film. These two reflected beams have a phase shift, and the shift is proportional to the thickness of the thin film. Waves are strengthened when they overlap in the same phase and weakened when they overlap in the opposite phase, making it possible to measure thickness by measuring the difference in interference.

2. Infrared Film Thickness Meter

This film thickness meter utilizes the absorption of infrared rays by the object to be measured. When an object is irradiated with infrared rays, certain wavelengths of infrared rays are absorbed depending on the material and thickness of the object to be measured. This property is used to measure the film thickness based on the spectrum obtained by spectroscopy of the transmitted or reflected light. If the relationship between the absorption rate of the material to be measured and the film thickness is measured in advance, the film thickness can be calculated.

3. Electromagnetic Film Thickness Meter

This is a film thickness meter that utilizes changes in magnetic flux density. This measurement method is used when the object to be measured is formed on a metallic surface with magnetism, and utilizes the fact that the magnetic flux density changes when a magnet is brought close to the metal only or when a magnet is brought close to the object to be measured while it is on the metal. However, this method can only be used when the object to be measured is in contact with metal and the object is not metal.

4. Eddy-Current Film Thickness Meter

The eddy-current film thickness meter uses the change in magnetic flux generated by a coil to measure the thickness of the object to be measured. When the coil is energized, magnetic flux is generated around the coil, and when the coil is brought close to the object to be measured, the magnetic flux changes according to the thickness of the object to be measured. The thickness of the object is measured by detecting this change in magnetic flux.

5. Ultrasonic Film Thickness Meter

An ultrasonic film thickness meter is a film thickness meter that utilizes the reflection of ultrasonic waves. When ultrasonic waves are emitted from the surface of the object to be measured, they pass through the interior of the object to be measured and are reflected on the reverse side. The thickness can be measured from the time it takes for this reflection to occur.

For example, when measuring the thickness of a transparent thin film such as glass, a spectral interference film thickness meter using a broadband light beam or an infrared film thickness meter using infrared light is used. On the other hand, these film thickness meters cannot be used for thin films that do not transmit light, such as metals.

When measuring thin films of metal plating, electromagnetic film thickness meters that use changes in magnetic flux or eddy-current film thickness meters that use eddy-currents are used. In addition, non-contact film thickness meters, such as ultrasonic film thickness meters, are also used when it is difficult to make contact with the object to be measured.

Types of Film Thickness Meters

Film thickness meters can be classified into three types: contact, non-contact, and cross-sectional observation.

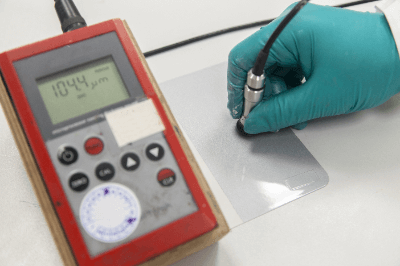

1. Contact Film Thickness Meter

In contact-type film thickness meters, the sensor part is connected to the main body of the meter by a cable, and the sensor part is brought into contact with the object to measure the film thickness. Contact-type film thickness meters include the electromagnetic induction type, overcurrent type, ultrasonic type, and stylus type. The most orthodox type of film thickness meter can be purchased for several tens of thousands to 200,000 yen, depending on its performance.

Using a contact-type film thickness meter is simple; just place the sensor part against the substance to be measured, and a numerical value will be displayed. However, since the reaction speed varies depending on the substance, you may have to wait a few seconds for the sensor to react. Among contact-type film thickness meters, the electromagnetic induction type and the overcurrent type must be used depending on the substrate on which the measurement is to be made.

The electromagnetic induction type is used for magnetic materials such as iron and steel, while the overcurrent type is used for nonmagnetic materials such as aluminum and stainless steel. Dual types that measure with both methods are also available. The dual type can measure both magnetic and non-magnetic materials.

2. Non-Contact Film Thickness Meter

Non-contact film thickness meters emit light from the body of the meter and measure film thickness by detecting the interference of wavelengths of light reflected from the surface of the film and penetrating into the film as a spectrum. Basically, this form is used in places inaccessible to the human hand. Reflectance spectrophotometer, infrared spectrophotometer, capacitance spectrophotometer, and radiation spectrophotometer are available. Since a high-precision semiconductor device is used for the detection part, the price is higher than that of the contact type.

3. Cross-Sectional Observation Type Film Thickness Meter

Cross-sectional film thickness meters are electron microscopes such as TEM and SEM. They are used to measure extremely small materials that cannot be measured with contact or non-contact methods. However, they are often used in research and technological development and are rarely employed in the field.