What Is a Vacuum Flange?

A vacuum flange is an essential component used in vacuum systems to connect various parts of the equipment while maintaining an airtight seal. It is a plate-shaped element that can be circular or square and features threaded holes or grooves for bolting purposes. Vacuum flanges play a critical role in creating a vacuum environment within the system, adhering to standards such as NW, KF, and JIS.

Uses of Vacuum Flanges

Vacuum flanges find application across industries that depend on vacuum environments for their processes, including:

1. Semiconductor Industry

Vacuum conditions are crucial for wafer fabrication in the semiconductor industry, where processes like deposition and etching are performed. Vacuum flanges ensure the chamber is sealed off from impurities while allowing the introduction of necessary gases and reactants.

2. Optical Device Industry

In optical equipment manufacturing, vacuum flanges are indispensable during the coating process of components like lenses and mirrors, enabling the precise and uniform application of thin films to enhance optical performance.

3. Power Generation

Vacuum flanges are used in steam turbines within condensers to convert steam back into water, maintaining a vacuum that enhances efficiency and performance.

4. Materials Research and Development

In R&D, particularly in physics and chemistry, vacuum flanges are crucial for conducting experiments under vacuum conditions to prevent contamination and accurately study the properties of materials.

Principles of Vacuum Flanges

Vacuum flanges ensure the airtightness of vacuum systems by using gaskets or packings at the joints, preventing external gas leakage. Materials like stainless steel (e.g., SUS316L, SUS304) or nickel alloys are used for their construction, with teflon packing or copper gaskets often employed as sealing materials to achieve optimal airtightness.

Types of Vacuum Flanges

Vacuum flanges are categorized by their standards and applications, including:

1. KF and NW Flanges

These modular flanges are suited for medium to high vacuum applications, utilizing sealing materials and clamps for hermetic connections, making them ideal for systems requiring frequent reconfiguration.

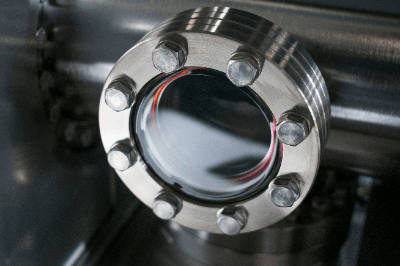

2. Conflat (CF Flange

CF vacuum flanges are designed for ultra-high vacuum applications, using metal gaskets for connections that withstand thermal cycling and chemical corrosion, ensuring high levels of tightness.

3. ANSI Flange

Adhering to the American National Standards Institute, these flanges are used in low vacuum and general piping systems, typically connected with bolts and nuts.

4. JIS Flange

JIS standard flanges are prevalent in vacuum equipment, offering standards for a wide range of industrial products and technologies.