What Is a Resistance Temperature Detector (RTD)?

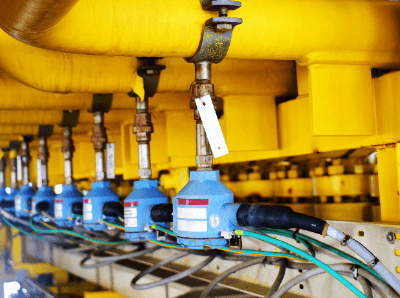

Resistance temperature detectors (RTD) are used in chemical plants to measure the temperature of process fluids (liquids and gases).

Resistance temperature detectors (RTDs), however, have less measurement error than thermocouples and are more accurate, especially at low temperatures. For this reason, they are often used when low temperatures are important or when high temperatures are not measured often.

They are also widely used in temperature measurement in chemical plants because they can be used for a wide variety of fluids if a protective tube is used.

Uses of Resistance Temperature Detectors (RTD)

Resistance temperature detectors (RTDs) are used to measure the temperature of process fluids (liquids and gases) flowing in pipes or tanks or stored. They are often used to display temperatures, especially when they are used to control or regulate temperatures.

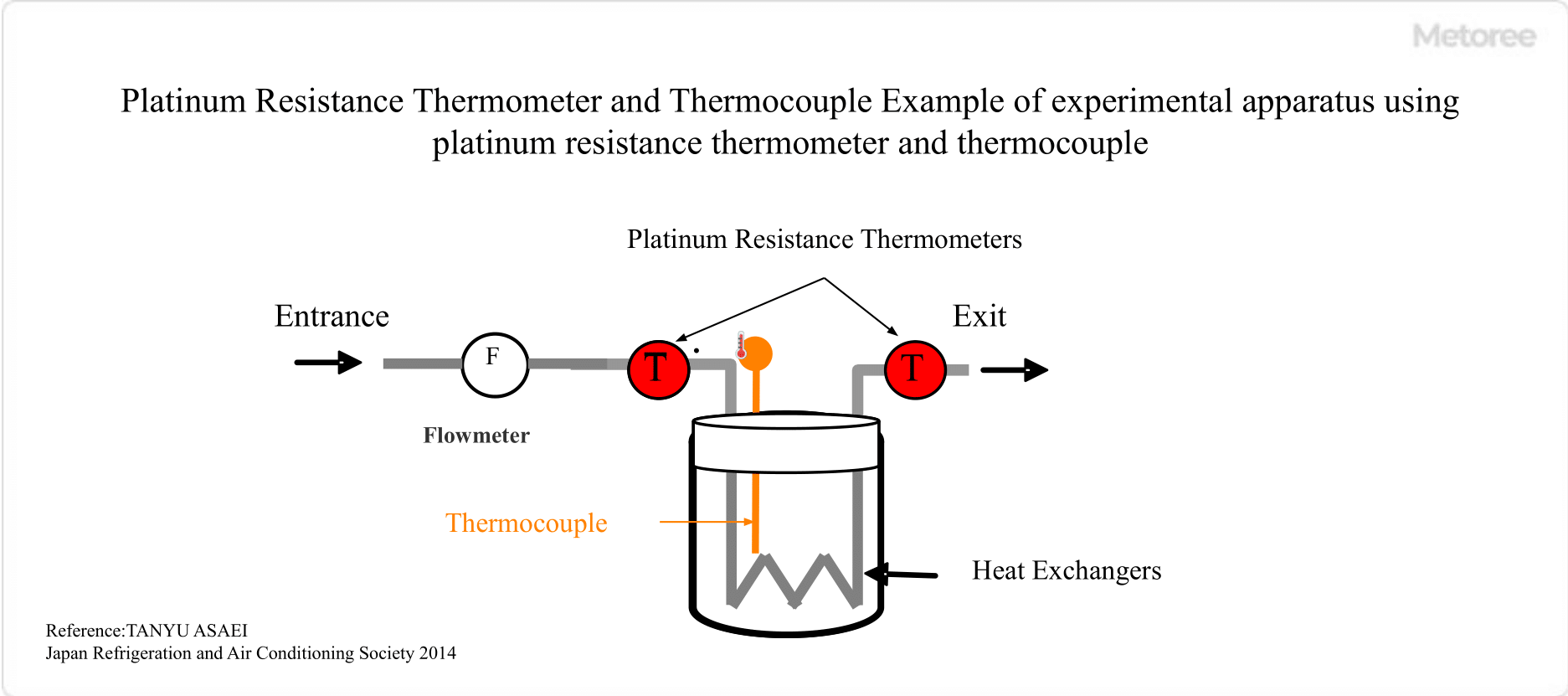

For example, the temperature of the cooling water at the inlet and outlet of a heat exchanger is measured to adjust the amount of cooling water according to the amount of heat exchanged. The temperature of a gas is measured when measuring the flow rate of an orifice flow meter to apply temperature compensation.

Resistance temperature detectors (RTD) have low temperature error and high accuracy, so they can be used to control locations where the temperature is not so high or to control or regulate low-temperature antifreeze, for example.

Principle of Resistance Temperature Detectors (RTD)

Resistance temperature detectors (RTD) measure changes in temperature by utilizing the property of a metal that its resistance value changes with temperature. Metals increase their resistance value as their temperature rises, and this characteristic is used in many cases, platinum is used.

For this reason, resistance temperature detectors (RTD) made of platinum, known as Pt100, are widely used in Japan. Also, since it is common to control and regulate the temperature in industrial processes by means of a 4-20 mA current, some products have a converter built into the terminal box of the resistance temperature detector (RTD) to enable a 4-20 mA output. Such products are very convenient because they eliminate the need for a converter in the control panel.

Resistance temperature detectors (RTD) are also specified by their grade. Although these devices can measure temperatures accurately with high precision, the required accuracy varies depending on the process fluid (liquid or gas) used, so consideration must be given. However, if the thermal response is slow, it may not work well depending on the physical properties of the process fluid (liquid or gas) used, so care must be taken when performing precise control or control.

Wiring Method for Resistance Temperature Detectors (RTD)

Resistance temperature detectors can be wired in three different ways: 2-wire, 3-wire, and 4-wire. 2-wire is the simplest method, with one wire at each end of the resistance temperature detector (RTD). However, the disadvantage is that the resistance of the wiring is added as it is. Since the resistance of the wiring must be measured and corrected in advance, it is not practical.

The 3-wire method is the most common wiring method, with two wires at one end of the resistance temperature detector (RTD) and one wire at the other end, and if the electrical resistance of the three wires is equal, the resistance of the wires can be ignored. The 4-wire type is more expensive, but the resistance of the wires can be completely disregarded.

Other Information on Resistance Temperature Detectors (RTD)

Comparison of Resistance Temperature Detector (RTD) And Thermocouple

Resistance temperature detectors (RTD) and thermocouples are both temperature measurement devices, but there are differences in temperature measurement range and accuracy.

1. Main Materials and Measuring Temperature Range

Resistance Temperature Detector (RTD)

Platinum, copper, nickel, and platinum-cobalt are available, each of which has a different temperature measurement range of up to 600°C.

Thermocouple

Platinum-rhodium alloy,” “nickel-chromium alloy,” “iron,” and “copper” are used, and their temperature measurement ranges differ. The superheat working temperature of B thermocouples is 1,700°C. For measuring high temperatures, thermocouples can be used. Thermocouples are used when measuring high temperatures.

2. Measurement Accuracy

Resistance Temperature Detector (RTD)

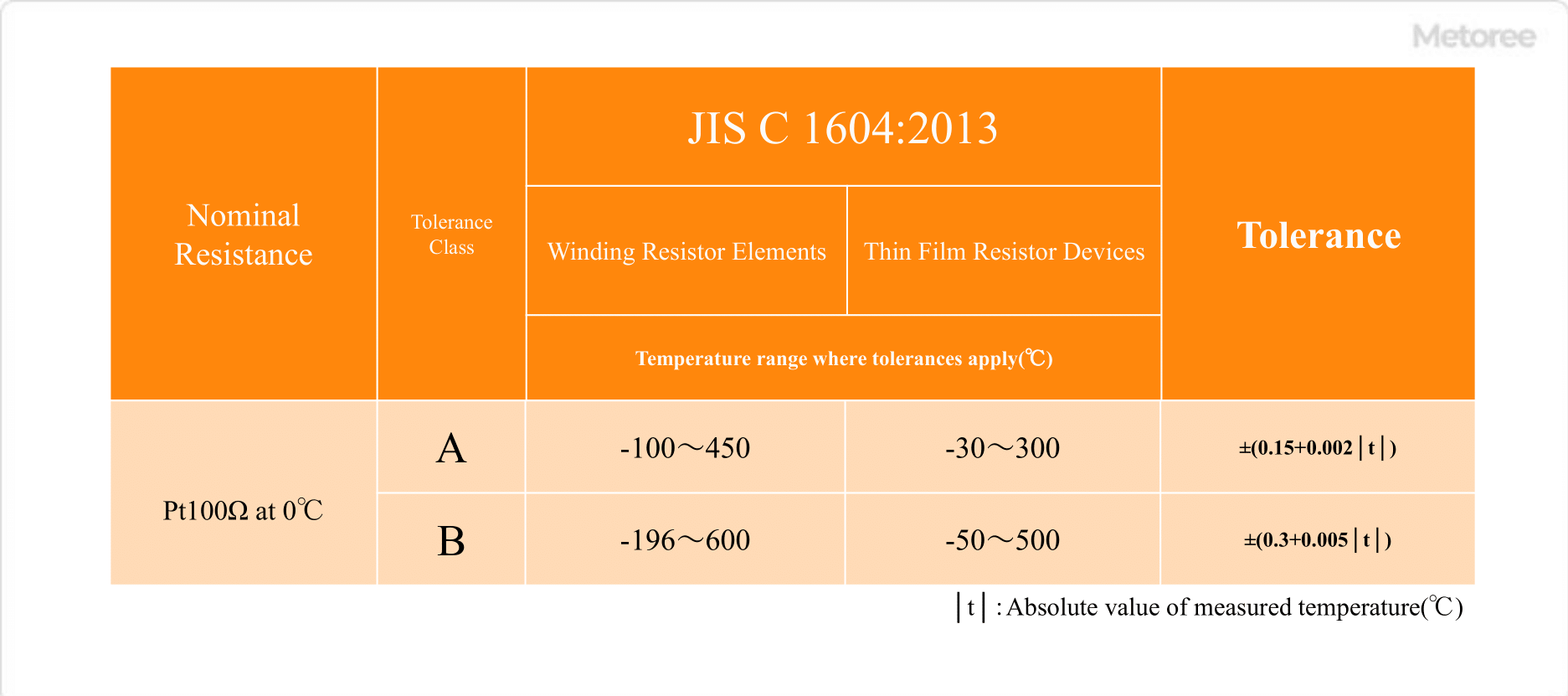

Tolerance of JIS C1604 standard for resistance thermometer

Resistance temperature detectors (RTD) are available in two measurement accuracy classes, A and B. Comparing the tolerances at 450°C, the maximum measurement temperature for Class A resistance temperature detectors (RTD), the tolerances are ±1.05 °C for Class A and ±2.55 °C for Class B.

Thermocouples

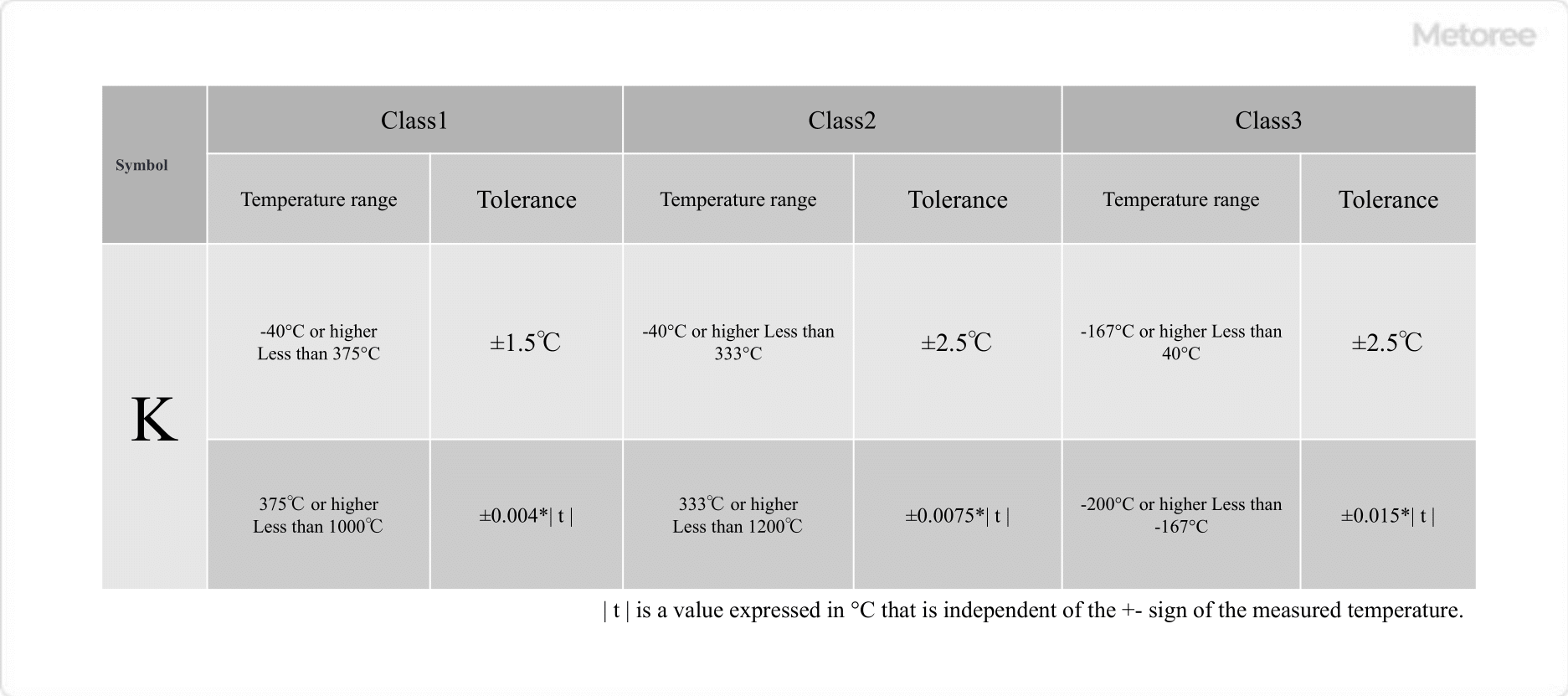

Thermocouple Temperature Tolerance

Thermocouples have measurement accuracy classes 1 to 3, which are specified for each measurement temperature range. When the thermocouple (K) is 450 °C, the tolerance is ±1.8 °C for Class 1, ±3.375 °C for Class 2, and 450 °C is not specified for Class 3. From the tolerances, it can be said that Resistance temperature detectors (RTD) have higher measurement accuracy than thermocouples, and are used for measurements that require high accuracy.