What Is a Hydraulic Nut?

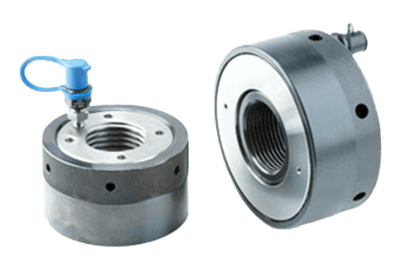

A hydraulic nut is a nut that is fastened by an axial force generated by hydraulic pressure, not by a screw.

The fastening force between a bolt and nut with a screw is generated by pulling up the axis of the screw using the screw’s helix. Hydraulic nut, on the other hand, uses hydraulic pressure to pull the bolt to generate the fastening force. As is the case with bolts that use screws, the nut can be subjected to torsion due to the frictional force of the screw, and variations in axial force can be suppressed.

No tightening tool is required because the bolt is pulled and fastened by a component that has a hydraulic function in the nut itself. The hydraulic nut is set on the bolt and a hose connected to a hydraulic pump is connected to the hydraulic nut supply port. By attaching the hose, multiple nuts can be tightened simultaneously. When hydraulic pressure is applied, oil is fed into the hydraulic nut, and the bolt is pulled to tighten.

A hydraulic nut uses a nonflammable glycol fluid instead of oil to provide the hydraulic function. The difference between a hydraulic nut and a bolt tensioner is that a hydraulic nut acts as a nut, whereas a bolt tensioner is set on the bolt and nut and removed after tightening, so it does not remain in place like a hydraulic nut.

Uses of Hydraulic Nuts

Hydraulic nuts are used in fastening relatively large-size bolts. The screws used are in the range of M20~300.

They are also used for mold fixing bolts for molding presses and injection molding machines and for the temporary fastening of large bolts on the mating surfaces of gas turbine and steam turbine casings for thermal power generation.

Principle of Hydraulic Nuts

A hydraulic nut uses hydraulic pressure to pull the bolt and generate an axial force on the bolt. Hydraulic pressure is based on Pascal’s principle, which states that when a certain force is applied to a sealed container of liquid, the pressure acts perpendicular to the surface of the container equally in all directions without reducing the volume.

The hydraulic nut allows the bolt to continue to generate the axial force on the bolt even after the hydraulic pressure is removed by allowing the nut to sit on the object to be fastened while the bolt is being pulled by the hydraulic pressure. When axial force is generated by an ordinary screw, the bolt will break at a lower axial force than simple tension because the friction of the threaded surface and the seating surface of the bolt’s head will cause the bolt to twist.

In addition, the frictional force of the screw and seat surface is variable, and when combined with the variation in tightening torque, there is typically a very large variation in axial force. With hydraulic nuts, the bolt is not subjected to torsion and the exact axial force can be determined from the hydraulic pressure.

Additional Information on Hydraulic Nuts

Advantages of Hydraulic Nuts

Hydraulic nuts can be used in tight places where a hydraulic torque wrench or bolt tensioner would have difficulty. Hydraulic nut is also suitable for tightening many bolts at the same time and evenly in other tight places where tools cannot enter. Tightening work is possible even in places with complicated shapes or where it is difficult for tools to enter if a hydraulic hose can be attached. Hydraulic nut is also suitable for tightening where the base shifts when the nut is tightened since there is no twisting power.

Compared to a hydraulic torque wrench, which controls torque, the hydraulic nut can be tightened more precisely without being affected by friction. By attaching a hose, multiple nuts can be tightened at the same time, thus eliminating variations in bolt tightening. Another advantage is that it prevents one-sided tightening of flanges and eliminates the need for diagonal tightening, thereby increasing work efficiency.

Hydraulic nuts are also useful when frequent and precise fastening and unfastening of multiple bolts and nuts is required, when loosening due to vibration is a concern, and in high-temperature locations. They are used in nuclear power plants because they are efficient and can be used at high temperatures, thus contributing to reduced worker exposure.

Unlike hydraulic torque wrenches used for manual tightening and torque management, this wrench does not twist the bolt and applies axial force directly, so there is no friction when tightening and highly accurate axial force management is possible. Also, since the bolt is not twisted, frictional heat is not generated, and there is no burning of the flange or threaded parts.