What Is an EDA Tool?

An EDA (Electronic Design Automation) tool is a set of software and hardware tools used to streamline and automate the electrical design process.

It can be thought of as the electrical design counterparts to the CAD and CAM tools commonly used in mechanical design.

For instance, in the design of household appliances, the product design journey typically begins with system (conceptual) design, followed by circuit design, assembly, iterative prototyping, and final product completion. Throughout this process, EDA tools play a crucial role in facilitating product design.

Applications of EDA Tools

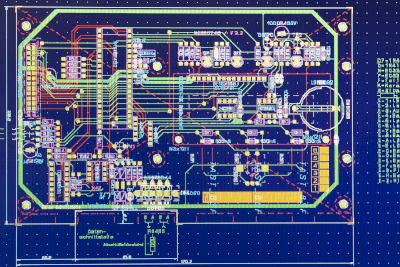

EDA tools cater to various stages of the design process. In the context of product design, including household appliances, they encompass tools for system (conceptual) design and simulation, which represents the initial design phase. Additionally, they encompass tools for circuit design and simulation, tools for printed circuit board layout, and tools for mitigating unwanted emissions.

In the semiconductor design field, EDA tools encompass tools for semiconductor device design and their simulation, logic and timing design tools and simulation tools, as well as layout design tools and simulation tools.

Principles of EDA Tools

It is technically possible to proceed with product design without employing EDA tools or by using only a subset of these tools.

However, in today’s competitive landscape, where manufacturers of various products, including household appliances and semiconductor devices, vie on a global scale, the notion of “build it, and it will sell” no longer applies. Success hinges on the ability to swiftly and cost-effectively deliver high-functionality, high-performance products. Consequently, circuits are becoming increasingly compact, smaller in size, lighter, and more power-efficient.

Remaining competitive necessitates an unmatched blend of development prowess and speed in this environment, and EDA tools serve as invaluable aids in achieving this.

The initial step in designing a product entails defining the product’s nature. What functions should it encompass? What should the production cost be? Subsequently, one must devise a system configuration that aligns with this cost target.

System design tools prove to be invaluable in this process. The simulation functionality of system design tools enables the evaluation of whether the virtual system configuration, conceived on a computer, is optimal. This involves assessing whether the performance, functionalities, and costs meet predefined expectations.

If simulation results prove unsatisfactory, the system can be reconfigured, and simulations rerun, iterating the trial-and-error process until an optimal system configuration is attained. Conducting this process by physically building a product would entail significant time and resources, but EDA tools empower users to conduct such verifications swiftly on a computer.

A similar approach can be employed in subsequent design phases, effectively shortening the overall design timeline.